Frustration can surge when the anticipation of powering up your generator is met with silence. Picture the scenario: you’re ready for action, the need for reliable power is paramount, but alas, the generator won’t start. In those moments, a mix of confusion and annoyance takes center stage. Fear not, for you’re not alone in this predicament.

We understand the importance of seamless power, and the hiccup of a non-starting generator can disrupt plans and leave you in the dark—both literally and figuratively. Let’s delve into the reasons behind this hiccup and illuminate the path to reigniting your power source.

Core Insights

- Fuel Issues: Ensure an adequate fuel supply; check for fuel leaks, stale fuel, or a clogged fuel filter as common culprits for a non-starting generator.

- Ignition Problems: Investigate the ignition system, including spark plugs and ignition coil, to address issues like poor spark or faulty connections that may hinder generator startup.

- Battery Troubles: Check the generator’s battery for charge levels and potential corrosion, as a weak or dead battery can impede the starting process.

- Maintenance Neglect: Regularly service your generator, addressing issues like air filters, oil changes, and overall upkeep, as neglecting maintenance can lead to starting failures.

12 Common Reasons Your Generator Won’t Start

Generators are invaluable during power outages, but encountering issues with starting can be a frustrating experience. Understanding the common reasons behind a non-starting generator can help troubleshoot and resolve the issue efficiently.

1. Fuel Issues: Insufficient or contaminated fuel can be a primary reason why your generator won’t start. If the fuel level is low or if the fuel is contaminated with water or debris, it disrupts the combustion process, hindering the engine from starting.

2. Dead Battery: A discharged or faulty battery is a common culprit for startup issues. The battery provides the initial electrical power to start the generator, and if it’s dead or malfunctioning, the starter motor won’t receive the necessary power to crank the engine.

3. Ignition System Problems: Issues with the ignition system, such as a faulty spark plug or ignition coil, can prevent the generation of sparks needed for combustion. A malfunctioning spark plug or ignition coil disrupts the ignition system, causing difficulties in starting the generator.

4. Airflow Restrictions: If there are restrictions in airflow, either due to a clogged air filter or blocked ventilation, it can disrupt the air-fuel mixture ratio. This imbalance makes it challenging for the generator to start, as the proper mixture is crucial for the combustion process.

5. Oil Level: Proper oil levels are essential for lubricating engine components. Low or dirty oil can increase friction, hindering the engine’s ability to start. Checking and maintaining the correct oil level is crucial for the overall health of the generator.

6. Choke Issues: Incorrect choke settings can lead to difficulties in starting the generator. The choke regulates the air-to-fuel mixture during startup, and if not set correctly, it can result in an imbalanced mixture, making it challenging for the generator to start.

7. Stale Fuel: Fuel left in the system for an extended period can degrade and lose its combustibility. Stale fuel may not ignite properly, causing starting issues for the generator. It’s important to use fresh, clean fuel to ensure proper combustion.

8. Low Coolant Levels: Inadequate coolant levels in the radiator can lead to overheating. Low coolant levels trigger safety mechanisms that prevent the generator from starting to avoid further damage. Checking and maintaining the coolant levels is crucial for preventing overheating issues.

9. Faulty Starter Motor: A malfunctioning starter motor is a critical component for initiating the engine’s cranking process. If the starter motor fails, the generator won’t be able to crank the engine, leading to startup issues.

10. Sensor Malfunctions: Issues with sensors, such as the oil pressure sensor or temperature sensor, can disrupt the normal startup sequence. Malfunctioning sensors may send incorrect signals to the generator’s control system, causing it to inhibit the startup process for safety reasons.

11. Dirty Spark Plug: A dirty spark plug can hinder the generation of sparks needed for combustion. Over time, carbon deposits or oil residues can accumulate on the spark plug, reducing its effectiveness.

12. Clogged Carburetor: A clogged carburetor restricts the proper mixing of air and fuel, affecting the combustion process. Debris or varnish buildup can block crucial passages and jets.

Facing any of these issues? Stay tuned for the next section, where we’ll explore practical solutions to get your generator up and running again.

What to do if the Generator Won’t Start?

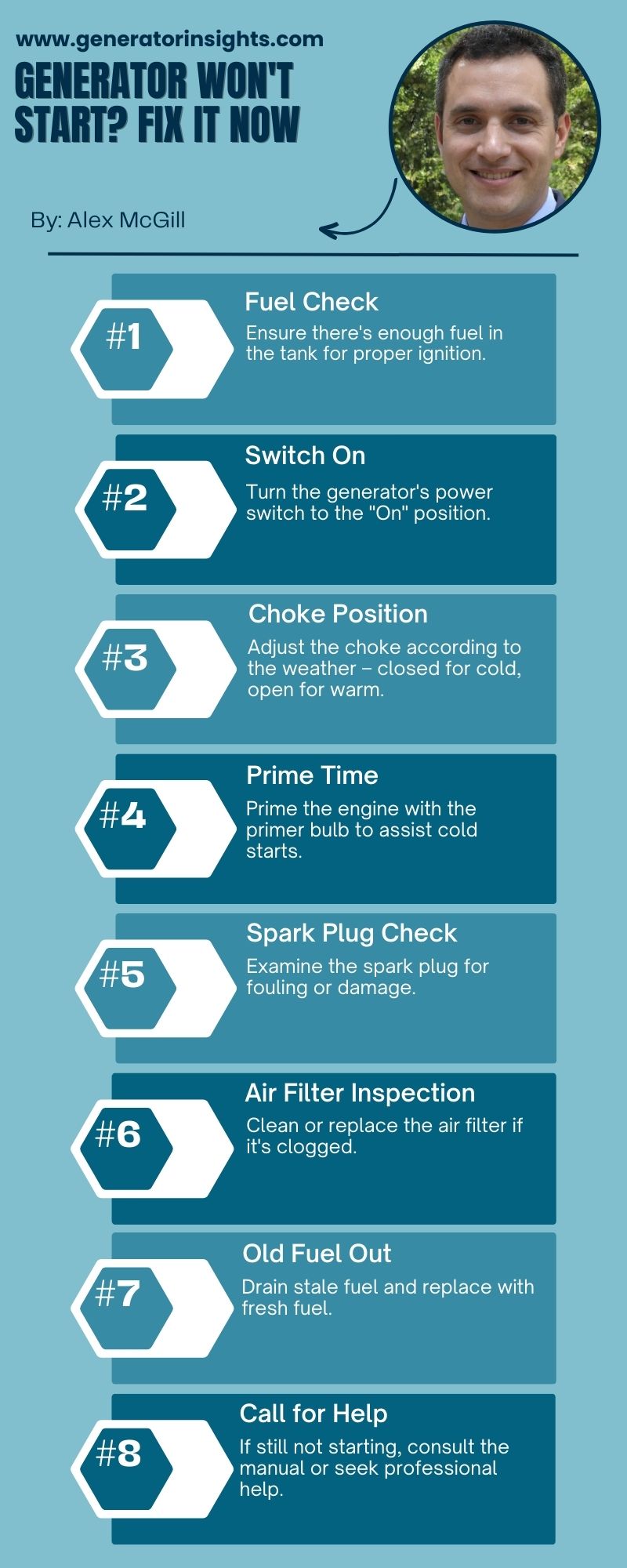

When your generator refuses to start, it can be a source of frustration, especially during critical times. However, fear not, as addressing the underlying issues is often a straightforward process. Here’s a step-by-step guide on what to do if your generator won’t start.

1. Fuel Issues:

- Check Fuel Level: Verify that there is an ample supply of fuel in the generator’s tank. Insufficient fuel can impede the combustion process, preventing the engine from starting.

- Inspect for Contamination: If the fuel appears contaminated with water or debris, drain the tank completely. Replace it with fresh, clean fuel to ensure proper combustion.

- Verify Fuel Valve: Confirm that the fuel valve is open. A closed valve restricts the flow of fuel to the engine, hindering the startup process.

2. Dead Battery:

- Charge or Replace Battery: If the battery is discharged, use an appropriate charger to replenish its charge. If the battery is old or unable to hold a charge, consider replacing it with a new, fully charged battery.

- Check Battery Connections: Ensure that the battery terminals are tightly connected and free from corrosion. Poor connections can prevent the battery from delivering sufficient power to the starter motor.

3. Ignition System Problems:

- Inspect and Replace Spark Plug: Examine the spark plug for signs of wear, fouling, or damage. If any issues are detected, replace the spark plug with a new, compatible one.

- Examine Ignition Coil: Inspect the ignition coil for visible damage or corrosion. A malfunctioning ignition coil can disrupt the spark generation process, leading to startup problems.

4. Airflow Restrictions:

- Clean or Replace Air Filter: If the air filter is dirty or clogged, clean it thoroughly or replace it with a new one. A clean air filter ensures proper air intake, crucial for the combustion process.

- Clear Ventilation Paths: Check for and remove any obstructions in the generator’s ventilation paths. Unrestricted airflow is essential for maintaining the correct air-fuel mixture.

5. Oil Level:

- Check and Replenish Oil Levels: Verify the oil level in the generator. If it’s below the recommended level, add the appropriate oil to bring it up to the required amount.

- Replace Dirty Oil: If the oil appears dirty or has exceeded its recommended usage, perform an oil change using the manufacturer-recommended oil.

6. Choke Issues:

- Adjust Choke Settings: Refer to the generator’s manual to determine the correct choke settings. Adjust the choke accordingly to achieve the optimal air-fuel mixture for startup.

7. Stale Fuel:

- Drain Stale Fuel: Remove any old or stale fuel from the generator’s system. Stale fuel can lead to ignition issues and may not combust effectively.

- Replace with Fresh Fuel: Refill the fuel tank with fresh, clean fuel to ensure a proper and efficient combustion process.

8. Low Coolant Levels:

- Check Coolant Levels: Inspect the coolant level in the radiator. If it’s below the recommended level, add the appropriate coolant to maintain proper engine temperature.

9. Faulty Starter Motor:

- Test Starter Motor: Utilize a multimeter to test the functionality of the starter motor. If it fails the test or exhibits signs of malfunction, consider repairing or replacing it to restore proper cranking.

10. Sensor Malfunctions:

- Inspect Sensors: Examine the oil pressure sensor, temperature sensor, and other relevant sensors for visible signs of damage or malfunction.

- Replace Faulty Sensors: If any sensors are found to be faulty, replace them with new ones according to the manufacturer’s specifications. Faulty sensors can disrupt the startup sequence and lead to engine inhibition.

11. Dirty Spark Plug:

- Remove and Inspect Spark Plug: Take out the spark plug and carefully inspect it for any dirt, carbon buildup, or oil deposits.

- Cleaning: If the spark plug is dirty but still in good condition, use a wire brush or special spark plug cleaner to remove carbon deposits and dirt.

- Replacement: If the spark plug is severely fouled, damaged, or worn out, consider replacing it with a new, compatible spark plug.

12. Clogged Carburetor:

- Disassemble the Carburetor: Carefully disassemble the carburetor, following the manufacturer’s guidelines and using the appropriate tools.

- Cleaning: Use a carburetor cleaner to remove debris, varnish, and old fuel from the carburetor components. Pay special attention to jets, passages, and the float bowl.

- Inspect and Replace Components: Examine all carburetor components for wear, damage, or deterioration. Replace any worn-out or damaged parts with new ones to ensure proper functioning.

- Reassemble the Carburetor: After cleaning and inspecting, reassemble the carburetor, ensuring that all components are correctly placed and tightened.

It is worth mentioning that before diving into these troubleshooting steps, ensure your safety by disconnecting the generator from any power sources and allowing it to cool down.

Moreover, once you’ve addressed the identified issues, attempt to start the generator again. If the problem persists, consider seeking professional assistance or consulting the manufacturer’s customer support for further guidance. Regular maintenance and timely troubleshooting ensure your generator remains a reliable power source when you need it the most.

Troubleshooting Common Generator Issues and their Fixes

| Issue | Possible Causes | Suggested Fixes |

|---|---|---|

| Low Power Output | – Dirty Air Filter | – Clean or replace air filter |

| – Exhaust System Blockage | – Check for obstructions in exhaust system | |

| – Incorrect Choke Settings | – Adjust choke settings according to the manual | |

| Engine Overheating | – Low Coolant Levels | – Inspect and replenish coolant levels |

| – Blocked Cooling System | – Clear blockages in the cooling system | |

| – Faulty Thermostat | – Test and replace if necessary | |

| Unstable Power Output/Voltage Fluctuations | – Dirty or Faulty Spark Plug | – Inspect, clean, or replace spark plug |

| – Fuel Quality Issues | – Ensure clean and fresh fuel | |

| – Voltage Regulator Malfunction | – Test and replace if necessary | |

| Excessive Noise | – Loose or Damaged Parts | – Tighten loose components; replace damaged parts |

| – Insufficient Lubrication | – Check and adjust oil levels; replace oil if necessary | |

| Generator Shuts Off Automatically | – Low Oil Level | – Check and replenish oil levels |

| – Fuel Issues | – Ensure constant and clean fuel supply | |

| – Overload Protection Activation | – Reduce connected load if overloaded | |

| Electric Shock from Generator | – Faulty Wiring | – Inspect and replace damaged wiring |

| – Grounding Issues | – Ensure proper grounding according to safety guidelines | |

| – Worn-out Insulation | – Replace worn-out insulation on wiring | |

| Smoke or Exhaust Issues | – Excessive Oil Consumption | – Check for oil leaks; replace worn-out seals |

| – Blocked Air Filter | – Clean or replace air filter | |

| – Fuel System Problems | – Inspect and clean fuel system components, including carburetor | |

| Inconsistent Running | – Carburetor Issues | – Clean or repair carburetor |

| – Ignition System Problems | – Inspect and replace faulty ignition components | |

| – Fuel Quality | – Use high-quality, clean fuel | |

| Excessive Vibration | – Loose Fasteners | – Tighten all nuts, bolts, and screws |

| – Damaged Engine Mounts | – Inspect and replace damaged engine mounts | |

| – Unbalanced Load | – Ensure an even distribution of connected electrical load |

Before attempting any troubleshooting or fixes, refer to the generator’s manual for specific guidelines and safety precautions. Seek professional assistance for complex problems that persist.

Seek Professional Help if Necessary

Seeking professional assistance is advisable if individuals encounter persisting difficulties with their generator’s starting mechanism, as experts possess the technical knowledge and expertise required to address complex issues effectively. Remember, ‘two heads are better than one’ when it comes to resolving challenging problems.

When it comes to troubleshooting a generator that won’t start, there are several common issues that individuals may encounter. These can include a faulty ignition system, a clogged fuel line or filter, a malfunctioning starter motor, or a problem with the carburetor. DIY troubleshooting techniques can be helpful in identifying and addressing some of these issues. However, if the problem persists after attempting these techniques or if individuals lack the necessary skills and knowledge to perform more advanced repairs, seeking professional help is strongly recommended.

By consulting professionals for assistance with generator starting problems, individuals can benefit from their experience in diagnosing and repairing various types of generators. Experts have access to specialized tools and equipment that may not be readily available to the average person. They also stay updated on the latest industry trends and best practices for generator maintenance and repair.

In conclusion, while DIY troubleshooting techniques can be useful for addressing some common generator starting issues, seeking professional help is essential for more complex problems. Professionals possess the technical expertise and resources necessary to diagnose and fix these issues effectively.

Conclusion

In conclusion, this guide on generator won’t start equips you with the tools to conquer generator woes and regain power during crucial times. The comprehensive exploration of potential causes, troubleshooting techniques, and effective fixes empowers you to tackle any starting obstacle head-on. Whether it’s a clogged fuel line or a faulty spark plug, this guide serves as your go-to resource for navigating generator issues.

As you embark on this journey of generator troubleshooting, let this guide be your trusted companion, offering step-by-step guidance and expert insights to ensure that your generator roars to life when you need it most.

References

- Optimal design of an enclosure for a portable generator

- Economics and market prospects of portable fuel cells

- Should we use a portable generator in an emergency?

- Carbon monoxide poisoning from portable electric generators