In the intricate dance between modern energy demands and sustainable solutions, natural gas emerges as a vital player in the symphony of power generation. Picture a world where homes are bathed in a warm glow, industries hum with productivity, and communities thrive with electricity harnessed seamlessly from the depths of the earth.

How is power generated from natural gas? becomes more than a question; it’s a gateway to understanding the heartbeat of our energy landscape. Join us on a journey where the power of innovation converges with the abundance of nature, creating a dynamic force that empowers lives and lights up possibilities.

Critical Insights

- Natural gas combustion is used to generate steam, which in turn propels turbines that convert mechanical energy into electricity.

- Combined cycle power plants maximize energy conversion efficiency and utilize waste heat to generate additional electricity.

- Natural gas generation has a lower environmental impact compared to coal, as it reduces carbon emissions and can employ emission reduction technologies.

- Integrating renewable energy with natural gas generation can contribute to long-term sustainability.

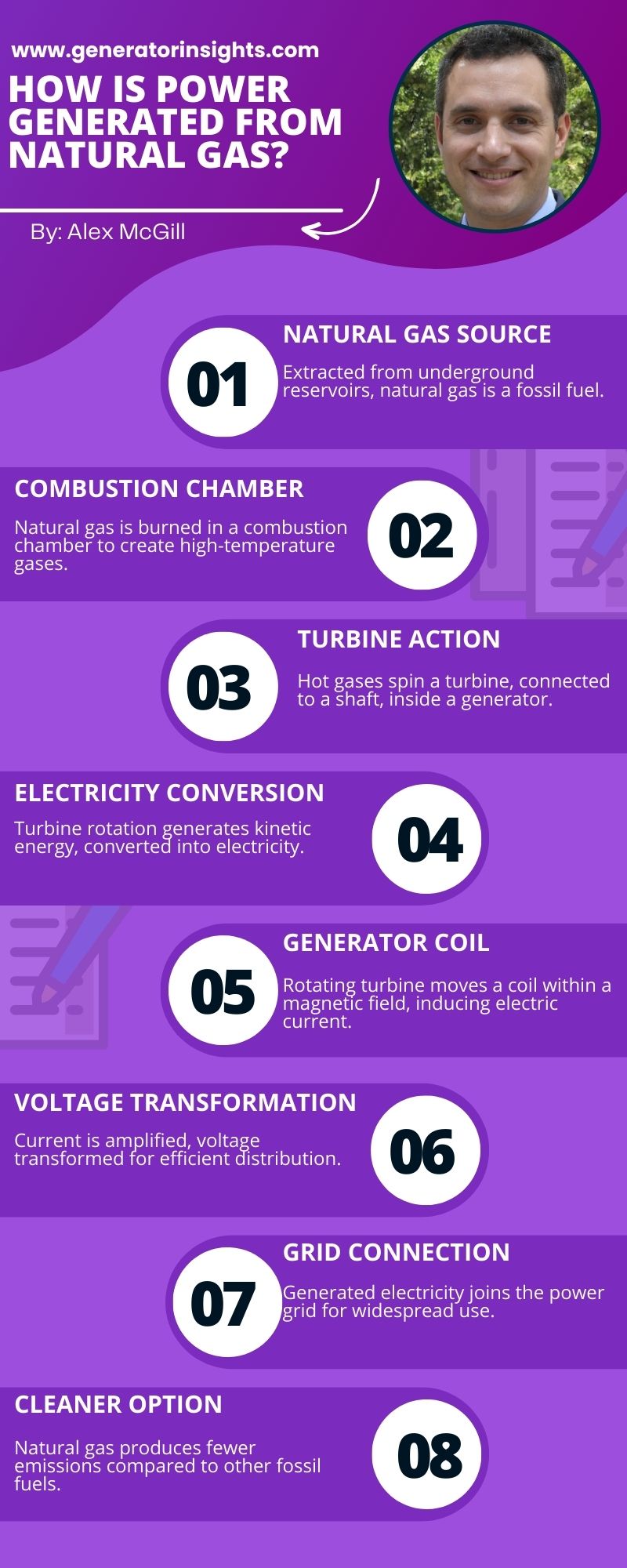

How Is Power Generated From Natural Gas?

Understanding how power is generated from natural gas is crucial in appreciating the role of this abundant and clean-burning fossil fuel in meeting our energy needs. Let’s delve into the process.

- Extraction of Natural Gas:

- Natural gas is primarily composed of methane and is often found in underground rock formations.

- Extraction involves drilling wells into these formations to release the trapped gas.

- Processing and Purification:

- Once extracted, natural gas undergoes processing to remove impurities like water, sulfur, and other contaminants.

- Purification ensures that the gas meets the quality standards required for power generation.

- Transportation to Power Plants:

- Natural gas is transported via pipelines or, in some cases, liquefied for easier transportation.

- It is then delivered to power plants, where the conversion process takes place.

- Combustion in Gas Turbines:

- At the power plant, natural gas is burned in gas turbines to produce high-temperature, high-pressure gas.

- The combustion process releases energy in the form of heat.

- Generation of Electricity:

- The hot gas is directed through a turbine, causing it to spin.

- This spinning turbine is connected to a generator, converting mechanical energy into electricity.

- Combined Cycle Power Plants (Optional):

- Some power plants use a combined cycle approach, where the hot exhaust gases from the gas turbine are used to produce steam.

- The steam is then used to drive a steam turbine, further enhancing the overall efficiency of power generation.

Now Let’s discuss all these points in detail.

Extraction of Natural Gas

The extraction of natural gas involves the drilling and fracturing of underground rock formations to release the trapped gas. This process typically begins with exploratory drilling, where geologists identify potential gas-rich areas. Once a suitable location is found, a well is drilled vertically into the ground. In some cases, horizontal drilling may be employed to access more extensive reservoirs.

After drilling, hydraulic fracturing, or ‘fracking,’ is used to extract natural gas from shale formations. This process involves injecting large volumes of water, sand, and chemicals into the well at high pressure. The injected fluids create fractures in the rock formation, allowing the trapped gas to flow towards the wellbore for collection.

Once extracted, natural gas undergoes several steps before it can be used as a power source. These include processing and treatment processes such as removal of impurities like carbon dioxide and hydrogen sulfide through various methods like absorption or adsorption. Additionally, liquefaction processes can convert natural gas into its liquid form (liquefied natural gas or LNG) for easier storage and transportation.

In summary, the extraction of natural gas involves drilling wells and using hydraulic fracturing techniques to release trapped gas from underground rock formations. Following extraction, further processing and treatment are necessary before it can be utilized as an energy source for power generation.

Processing and Treatment of Natural Gas

Processing and treating the abundant resource involves a series of complex techniques to ensure its purity and viability as an energy source. Natural gas undergoes several processing techniques and purification methods before it can be used for generating power. The main purpose of these processes is to remove impurities, such as water vapor, carbon dioxide, sulfur compounds, and other contaminants that may affect the quality of the gas.

One commonly used method for processing natural gas is called ‘sweetening’, which involves removing hydrogen sulfide (H2S) from the gas stream. This is done through a process known as amine treatment or amine scrubbing, where a solution containing chemicals called amines reacts with H2S to form stable compounds that can be easily separated from the gas.

Another important step in processing natural gas is dehydration, which involves removing water vapor from the gas stream. Water vapor can cause corrosion in pipelines and reduce the calorific value of the gas. Dehydration is typically achieved by cooling down the gas and then passing it through a bed of desiccant material or using specialized membranes.

To give you an overview of these processing techniques and purification methods, here’s a table:

| Processing Technique | Purpose |

|---|---|

| Sweetening | Remove H2S |

| Dehydration | Remove water vapor |

After undergoing these processes, natural gas becomes purified and ready for transportation via pipelines or other means.

Transportation of Natural Gas

Transportation of natural gas is a critical aspect of the energy industry, ensuring the efficient delivery of this valuable resource to consumers and industries around the world. To achieve this, a well-developed pipeline infrastructure has been established, enabling the transportation of natural gas over long distances. These pipelines are interconnected networks that span across countries and continents, allowing for continuous flow from production sites to end-users.

In addition to pipeline transportation, liquefied natural gas (LNG) plays a vital role in global trade. Natural gas can be cooled to -162 degrees Celsius, transforming it into a liquid state that occupies 1/600th of its original volume. This process facilitates transportation through specialized LNG carriers, which transport the LNG to various destinations worldwide. Once at its destination, LNG is regasified and injected into local pipeline systems for distribution.

The extensive pipeline infrastructure and LNG transportation ensure a steady supply of natural gas to power plants and other industries globally. This reliable delivery system allows for an uninterrupted energy supply that supports economic growth and development.

Transitioning into the subsequent section about the combustion process, once natural gas reaches its destination through efficient transportation methods, it undergoes combustion to generate power.

Combustion Process

Combustion of natural gas in power plants and industrial facilities is a widely adopted process, despite concerns regarding its environmental impact. Natural gas is primarily composed of methane, which is a potent greenhouse gas. However, advancements in technology have allowed for the development of combustion systems that significantly reduce emissions and increase combustion efficiency.

One key aspect of the combustion process is ensuring high combustion efficiency. This involves achieving complete combustion of the natural gas, which means that all available energy from the fuel is converted into heat. Efficient burners are used to provide an optimal air-to-fuel ratio, ensuring the maximum utilization of natural gas while minimizing waste.

To further mitigate environmental impacts, emissions control technologies are employed. These technologies aim to reduce pollutant emissions such as nitrogen oxides (NOx), sulfur dioxide (SO2), carbon monoxide (CO), and particulate matter.

Combustion systems incorporate techniques like flue gas recirculation, selective catalytic reduction, and wet scrubbers to capture and treat these pollutants before they are released into the atmosphere.

The combination of high combustion efficiency and effective emissions control measures helps minimize the environmental footprint associated with natural gas combustion processes.

In the subsequent section about ‘steam generation,’ this high-efficiency combustion will play a crucial role in producing steam for generating electricity without excessive resource consumption or pollution.

Steam Generation

Steam generation plays a crucial role in the overall efficiency and productivity of power plants and industrial facilities. The process involves heating water to produce steam, which drives turbines to generate electricity. Steam pressure is an important factor in this process, as it determines the energy output of the turbine. Higher steam pressures generally result in greater turbine efficiencies and increased power generation.

Significance of Steam Pressure in Power Plant Operations

- Higher steam pressures lead to improved turbine efficiencies, resulting in higher power outputs.

- Increased steam pressure allows for more work to be extracted from the same amount of fuel, enhancing overall plant efficiency.

- High-pressure steam requires less space than low-pressure steam, allowing for smaller equipment sizes and reduced installation costs.

Importance of Turbine Efficiency

- Turbine efficiency directly affects power plant performance by determining how much useful work can be extracted from a given amount of heat energy.

- Improving turbine efficiency decreases fuel consumption and reduces greenhouse gas emissions, making power generation more sustainable.

- Advances in technology have led to more efficient turbines that can operate at higher temperatures and pressures, increasing overall system performance.

Transitioning into the subsequent section about electricity generation, it is essential to understand how generated steam is utilized further.

Electricity Generation

Utilizing the transformative force of electricity, the generated steam propels turbines with remarkable efficiency, ushering in a new era of power production.

Electricity generation plays a crucial role in harnessing the potential energy stored in natural gas. After steam is produced through the combustion of natural gas, it is directed to high-pressure turbines where its kinetic energy is converted into mechanical energy. This mechanical energy then drives generators that produce electrical power.

Power transmission is an essential aspect of electricity generation from natural gas. The electrical power generated must be transmitted efficiently from the power plant to consumers over long distances without significant losses. To achieve this, high-voltage transmission lines are used to transport electricity at higher voltages, reducing resistive losses during transmission.

Furthermore, integrating renewable energy sources with natural gas-based electricity generation has become increasingly important. As renewable energy technologies like solar and wind produce intermittent power outputs, they can be complemented by natural gas plants that provide stable baseload power. This integration allows for a reliable and resilient electric grid that incorporates both conventional and sustainable sources.

Transitioning into the subsequent section about combined cycle power plants, these systems further enhance efficiency by utilizing waste heat from the initial combustion process to generate additional electricity using a steam turbine cycle.

Combined Cycle Power Plants

One essential aspect of combined cycle power plants is their ability to maximize energy conversion efficiency. These plants are designed to generate electricity by using both gas and steam turbines in a sequential manner, which results in higher overall efficiency compared to traditional single-cycle power plants.

The key advantage of this technology lies in its ability to harness the waste heat produced during the gas turbine process, which is then used to produce steam that drives a steam turbine.

By utilizing this waste heat, combined cycle power plants can achieve thermal efficiencies as high as 60%. This is significantly higher than the average thermal efficiency of conventional power plants, which typically ranges from 30% to 40%.

The use of advanced turbine technology also contributes to these efficiency advantages. Gas turbines used in combined cycle power plants are often equipped with advanced aerodynamic designs and materials that allow for more efficient energy conversion.

In addition, the combination of gas and steam turbines allows for better flexibility in responding to fluctuations in electricity demand. Gas turbines have a shorter start-up time compared to steam turbines, making them suitable for meeting sudden increases in demand. On the other hand, steam turbines provide stable output over longer periods.

With such impressive efficiency advantages and improved responsiveness, combined cycle power plants have become an increasingly popular choice for electricity generation worldwide.

How a Gas Turbine Works?

Gas turbines, also known as combustion turbines, are widely used for power generation. These engines operate on the principle of converting energy from fuel into mechanical energy. Let’s delve into the intricate details of how a gas turbine works:

- Air Intake:

- Introduction of Air: The process begins with the turbine drawing in atmospheric air through its air intake.

- Compression: The air undergoes compression, where it is squeezed to increase pressure and temperature.

- Combustion:

- Fuel Injection: A crucial step involves injecting fuel into the compressed air within the combustion chamber.

- Ignition: The mixture of fuel and air is ignited, resulting in a high-temperature, high-pressure combustion.

- Expansion:

- Turbine Blades: The expanding, high-velocity gases produced during combustion pass through turbine blades.

- Mechanical Energy Conversion: As the gases flow over the turbine blades, they cause the blades to spin, converting thermal energy into mechanical energy.

- Exhaust:

- Exhaust System: The remaining high-velocity gases exit the turbine through the exhaust system.

- Energy Extraction: The energy extracted during expansion is now converted into mechanical energy to perform useful work.

- Power Generation or Propulsion:

- Generator: In a power generation context, the rotating turbine shaft is connected to a generator, producing electrical power.

Environmental Impact of Using Natural Gas

Natural gas has become a popular choice for energy generation due to its efficiency and relatively lower environmental impact compared to some traditional fuels. The environmental impact of using natural gas for energy generation is a multifaceted topic that involves examining various aspects, from extraction to combustion.

Natural gas extraction, often associated with hydraulic fracturing or fracking, raises environmental concerns. The process can lead to habitat disruption, water pollution, and the release of methane—a potent greenhouse gas. However, advancements in extraction technologies aim to mitigate these environmental impacts.

Once extracted, natural gas is transported to power plants, where it plays a pivotal role in electricity generation. The combustion of natural gas produces fewer greenhouse gas emissions compared to coal or oil, contributing to its reputation as a cleaner-burning fuel. In particular, natural gas power plants emit lower levels of carbon dioxide (CO2), sulfur dioxide (SO2), and nitrogen oxides (NOx), which are major contributors to air pollution and climate change.

Moreover, the combustion process of natural gas is more efficient than some other fossil fuels, resulting in a higher energy yield per unit of CO2 emitted. This efficiency contributes to the overall reduction of greenhouse gas emissions per unit of energy produced, aligning with efforts to transition to more sustainable energy sources.

Cogeneration, a process where natural gas is used for both electricity generation and heat production, further enhances the environmental benefits. This dual-use approach maximizes the energy extracted from natural gas, reducing overall resource consumption and emissions.

However, it’s essential to note that while natural gas is considered a cleaner-burning fuel, it is not without environmental challenges. The extraction process requires careful management to prevent environmental degradation, and the combustion of natural gas still contributes to climate change, albeit to a lesser extent than some alternatives.

In conclusion, the environmental impact of using natural gas for energy generation involves a complex interplay of extraction, transportation, and combustion factors. While advancements in technology and energy practices aim to mitigate these impacts, a holistic approach that considers the entire life cycle of natural gas is crucial for sustainable energy use. Balancing the benefits and challenges, including the environmental considerations, is vital as we navigate the transition to a more sustainable energy future.

Conclusion

In conclusion, the process of generating power from natural gas is a remarkable fusion of cutting-edge technology and environmental consciousness. As we navigate the complexities of natural gas extraction, transportation, and conversion, it becomes evident that this resource holds the key to a greener and more energy-efficient tomorrow.

Embrace the power of natural gas as a pivotal player in the global energy landscape, propelling us towards a brighter, sustainable future. With a commitment to innovation and responsible energy consumption, we can continue to harness the potential of natural gas and pave the way for a world powered by cleaner and more efficient energy sources.

References

- Biomechanical energy‐driven hybridized generator as a universal portable power source for smart/wearable electronics

- Portable fuel cell power generator

- A thermophotovoltaic micro-generator for portable power applications

- Fuel cells-the clean and efficient power generators