Navigating the world of portable generators can be a power-packed adventure, but what happens when it’s time to hit the off switch? Picture this: a serene camping trip or a backyard gathering powered by your trusty generator, and now the festivities are winding down. How do you gracefully bid adieu to the hum of electricity?

In this guide on how to turn off a portable generator, we’ll unravel the simplicity behind the process. No more fumbling in the dark or questioning if you’ve got it right. Let’s make shutting down your generator as seamless as the moments it brought to life, ensuring your power-down is as smooth as your power-up.

Core Insights

- Disconnect all electrical loads before shutting down the generator to prevent power surges or backfeed.

- Turn off the fuel supply by closing the fuel valve to reduce the risk of fires or explosions.

- Allow the generator’s engine ample time to cool down before refueling or performing maintenance tasks.

- Follow specific manufacturer guidelines for proper shutdown procedures.

What is a Portable Generator and How it Works?

Portable generators are versatile power solutions designed to provide electricity on the go. These compact units are particularly useful in situations where a stable power source is unavailable or during emergencies like power outages. A portable generator operates on the principle of converting mechanical energy into electrical energy through a process known as electromagnetic induction.

Generators consist of two main components: an engine and an alternator. The engine, often powered by gasoline or propane, drives a crankshaft, creating rotational motion. This motion is then transferred to the alternator, which houses a coil of wire within a magnetic field. As the coil spins within the magnetic field, it generates an electric current.

The voltage produced by the generator is determined by the speed at which the engine drives the alternator. Most portable generators are designed to produce alternating current (AC), the standard type of electricity used in homes and businesses. The AC power generated can be used to run various appliances and electronic devices through the generator’s outlets.

Portable generators are equipped with features such as circuit breakers and voltage regulators to ensure a stable and safe power supply. Additionally, many models offer multiple outlets and different power levels to accommodate a range of electrical needs.

In summary, a portable generator is a mobile power source that converts mechanical energy into electrical energy through electromagnetic induction. Its compact design and versatility make it an essential tool for various applications, from camping and outdoor activities to emergency backup power during outages.

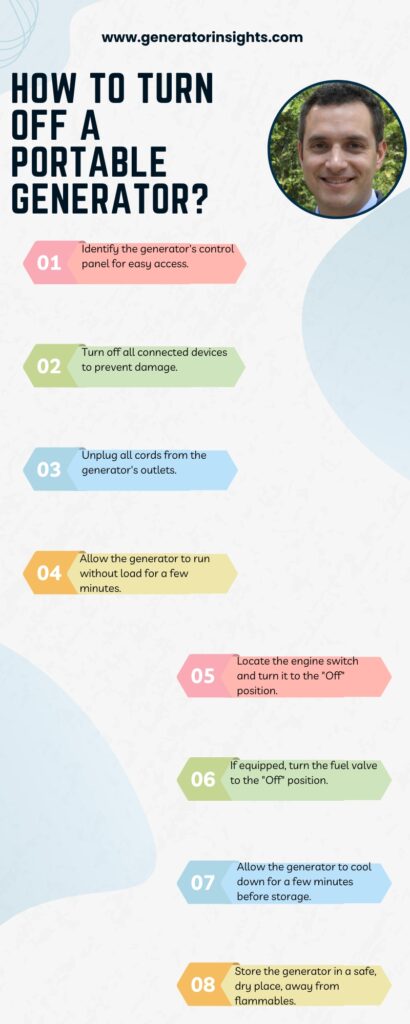

How to Turn off a Portable Generator?

When it comes to safely shutting down a portable generator, following the correct procedure is crucial for both your equipment’s longevity and your safety. Here’s a step-by-step guide:

- Locate the Fuel Valve:

- Find the fuel valve on the generator. It’s typically located near the fuel tank.

- Gently turn the valve to the “OFF” position to stop the fuel flow.

- Switch Off the Generator:

- Locate the generator’s power switch.

- Move the switch to the “OFF” position to stop the electrical output.

- Let it Cool Down:

- Allow the generator to run without any load for a few minutes to cool down the engine.

- This prevents potential damage and ensures a smoother restart.

- Disconnect Electrical Loads:

- Unplug or turn off all devices connected to the generator.

- This prevents any power surges or fluctuations when shutting down.

- Close the Choke:

- If your generator has a choke, engage it to restrict airflow to the engine.

- This aids in a smoother shutdown and restart.

- Pull the Recoil Cord:

- If your generator has a recoil starter, pull the cord until you feel resistance.

- This ensures the engine is in the compression stroke, ready for the next start.

- Store in a Safe Place:

- Once the generator is off and cool, store it in a dry and well-ventilated area.

- Protect it from the elements to prolong its lifespan.

Remember, following these steps ensures a proper shutdown and prepares your portable generator for the next use. Always consult your generator’s manual for specific instructions, and adhere to recommended safety guidelines.

How Do I Shut Down my Standby Generator while Under Load for Maintenance?

When it comes to maintaining a standby generator, shutting it down properly under load is a crucial task. This ensures a smooth transition without causing disruptions or damage. Here’s a step-by-step guide on how to safely shut down your standby generator while under load for maintenance:

- Check Load Status:

- Before initiating the shutdown process, identify the current load on the generator. This information is essential for a controlled shutdown.

- Notify Users:

- Communicate with relevant stakeholders and users to inform them about the upcoming shutdown. Ensure they are aware of potential disruptions during this maintenance period.

- Reduce Load Gradually:

- Begin by reducing the load gradually rather than an abrupt cut-off. This prevents sudden power interruptions and allows the system to adjust smoothly.

- Monitor Parameters:

- Initiate Shutdown Sequence:

- Follow the manufacturer’s recommended shutdown sequence for your standby generator. This typically involves activating the control panel and initiating the shutdown process.

- Allow Cooling Time:

- After the load is fully reduced, allow the generator to run at a no-load condition for a few minutes. This helps in cooling down components before the final shutdown.

- Shut Down Completely:

- Once the generator has cooled sufficiently, proceed to shut it down completely according to the manufacturer’s guidelines. This often involves turning off the engine and the control panel.

- Verify Shutdown:

- Double-check that the generator has completely powered down. Confirm that all indicators show a safe and inactive status.

How to Deal with Emergency Shutdowns?

During an emergency shutdown of a generator, quick and effective action is crucial. Generators are vital for a consistent power supply, so having a clear strategy for emergencies is essential.

- Basic Understanding: Preventing emergency shutdowns is key. Regular maintenance, including checks for fuel levels, oil quality, and overall generator condition, helps identify issues before they become serious.

- Monitoring Systems: Consider using advanced monitoring systems. They provide real-time data on the generator’s performance, allowing you to address potential problems before they lead to a shutdown.

- Emergency Response Plan: Develop a comprehensive plan for generator shutdowns. Clearly outline team roles and responsibilities, ensuring everyone is well-trained to minimize downtime.

- Redundancy Measures: Implement backup plans. Have a standby generator or use automatic transfer switches to switch to an alternate power source in case of failure.

- Troubleshooting: Follow a systematic troubleshooting procedure in case of a shutdown. Identify the root cause by examining logs and diagnostic information, addressing issues methodically.

- Example: For instance, if a generator shuts down due to overheating, check coolant levels, inspect the radiator, and ensure proper ventilation for a prompt resolution.

- Documentation and Analysis: Keep detailed documentation of each shutdown. Analyze data to identify recurring patterns, informing future preventive measures and reducing the likelihood of similar incidents.

- Training and Drills: Conduct regular training sessions and drills to familiarize the team with the emergency response plan. Simulating shutdown scenarios enhances their ability to act swiftly during a real emergency.

By combining proactive maintenance, advanced monitoring, and a well-prepared response, you can effectively manage emergency shutdowns, minimizing their impact on your power supply system.

How to Store a Generator Properly?

When it comes to ensuring the longevity and optimal performance of your generator, proper storage is key. Whether it’s a backup power source for emergencies or a portable unit for outdoor activities, taking the right steps to store your generator can prevent issues and extend its lifespan.

Choosing the Right Location: Begin by selecting a dry and well-ventilated area for storing your generator. Exposure to the elements, especially moisture, can lead to rust and damage critical components. A dedicated storage shed is ideal, providing protection from rain, snow, and extreme temperatures.

Fuel Considerations: Before storing your generator, it’s crucial to address the fuel situation. Drain the fuel tank or add a fuel stabilizer to prevent the formation of deposits and varnish. Storing the generator with a full tank of stabilized fuel helps prevent condensation and keeps the fuel system in good condition.

Oil Maintenance: Check the oil level and quality before storing the generator. If the oil is dirty, change it according to the manufacturer’s recommendations. Clean oil ensures that the engine is adequately lubricated during storage, preventing corrosion and maintaining internal components.

Battery Care: If your generator has a battery, make sure it’s fully charged before storage. A disconnected or removed battery is a good practice, especially if the generator won’t be used for an extended period. Store the battery in a cool, dry place to prevent self-discharge.

Covering and Protection: Shield your generator from dust and debris by covering it with a breathable and weather-resistant cover. This helps to keep the unit clean and prevents any unwanted intrusions that could affect its functionality. Avoid using plastic or non-breathable materials that can trap moisture.

Run the Generator Periodically: To keep internal components lubricated and prevent stale fuel buildup, run the generator for about 15-20 minutes every three months. This process helps maintain its functionality and readiness.

Regular Maintenance Schedule: Even in storage, it’s essential to maintain a periodic schedule for checking your generator. This includes starting the unit every few months to circulate oil and keep internal components lubricated. Following the manufacturer’s guidelines for maintenance during storage ensures that your generator is ready when needed.

Troubleshooting Common Generator Issues

Generators are invaluable during power outages, but issues can arise. Understanding how to troubleshoot common problems ensures your generator stays reliable.

| Issue | Possible Causes | Troubleshooting Tips |

|---|---|---|

| 1. No Power Output | – Fuel Level: Low fuel can hinder power generation. | – Ensure fuel tank is filled adequately. |

| – Spark Plug: A faulty spark plug may disrupt ignition. | – Check and replace the spark plug if needed. | |

| – Air Filter: A clogged air filter can impede performance. | – Clean or replace the air filter regularly. | |

| 2. Engine Won’t Start | – Battery: Weak or dead batteries can prevent startup. | – Check and charge the battery or replace if necessary. |

| – Oil Level: Low oil levels may trigger a safety shutdown. | – Confirm oil level is within the recommended range. | |

| – Starter Motor: Malfunctions in the starter motor can occur. | – Inspect and repair or replace the starter motor. | |

| 3. Overheating | – Coolant Level: Insufficient coolant may lead to overheating. | – Monitor and maintain the coolant level regularly. |

| – Airflow: Blocked vents or fans can impede proper cooling. | – Clear any debris obstructing airflow around the generator. | |

| – Operating Conditions: Excessive load or prolonged use can cause overheating. | – Avoid overloading and allow the generator to cool between extended use. | |

| 4. Unstable Power Output | – Voltage Regulator: A faulty regulator may cause fluctuations. | – Check and replace the voltage regulator as needed. |

| – Fuel Quality: Contaminated fuel can affect power stability. | – Use high-quality, clean fuel to prevent issues. | |

| – Electrical Connections: Loose connections can lead to instability. | – Inspect and tighten all electrical connections. |

Understanding these common issues and their solutions will help you keep your generator in optimal working condition, ensuring a reliable power source when you need it the most.

Generator Maintenance Tips

Ensuring your generator runs smoothly is crucial for uninterrupted power supply. Follow these generator maintenance tips to keep your equipment in optimal condition.

- Regular Inspections:

- Perform monthly visual inspections to spot any leaks, loose connections, or worn-out parts.

- Check the fuel and oil levels to guarantee proper functionality.

- Oil Changes:

- Change the oil after every 100 hours of operation to prevent engine damage.

- Use the manufacturer-recommended oil type and viscosity for optimal performance.

- Air Filter Checks:

- Inspect the air filter regularly, and replace it if it’s dirty or clogged.

- A clean air filter ensures efficient combustion and fuel consumption.

- Battery Care:

- Keep the generator battery terminals clean and corrosion-free to ensure a reliable start.

- Test the battery periodically and replace it if it shows signs of weakness.

- Cooling System Maintenance:

- Check the coolant level and top it up as needed to prevent overheating.

- Clean the radiator and cooling fins to maintain efficient heat dissipation.

- Run the Generator Regularly:

- Operate the generator at least once a month with a load to prevent fuel system issues.

- This helps keep the engine and various components in good working order.

- Store Fuel Properly:

- Use clean and stabilized fuel to prevent carburetor clogs and fuel system problems.

- Rotate stored fuel to ensure freshness and avoid engine issues.

- Professional Servicing:

- Schedule annual professional maintenance to address potential problems and extend the generator’s lifespan.

- Professional technicians can conduct in-depth inspections and address issues you might overlook.

By adhering to these generator maintenance tips, you’ll enhance the longevity and reliability of your power source, ensuring it’s ready when you need it most.

Generator Safety Tips

Power outages can happen unexpectedly, making generators a valuable asset. However, ensuring their safe use is crucial. Here are essential tips to keep in mind:

- Location Matters: Place your generator in a well-ventilated area, ideally outdoors, to prevent carbon monoxide buildup.

- Read the Manual: Familiarize yourself with your generator’s manual for proper operation and maintenance instructions.

- Fuel Storage: Store generator fuel in a cool, well-ventilated place, away from potential ignition sources.

- Regular Inspections: Conduct routine checks for fuel leaks, loose connections, and any signs of wear on cables.

- Grounding: Properly ground your generator to minimize the risk of electrical shocks and ensure safe operation.

- Keep it Dry: Protect your generator from the elements by using a generator tent or covering during rainy conditions.

- Load Management: Avoid overloading your generator by calculating the total wattage of connected devices.

- Exhaust Direction: Position the generator’s exhaust away from windows and doors to prevent fumes from entering enclosed spaces.

- Cooling Time: Allow the generator to cool down before refueling to prevent accidents and ensure safe handling.

Remember, prioritizing safety when using generators is essential for both your well-being and the longevity of the equipment.

Conclusion

In conclusion, knowing how to turn off a portable generator is an essential skill that guarantees the safety of both you and your equipment. By following the steps outlined in this guide, you can ensure a smooth and hassle-free shutdown process. Remember to prioritize safety measures and allow the generator to cool down before storing it. Let this guide be your trusted resource in mastering the art of generator operation.

With this knowledge, you can confidently navigate any situation, from powering down after an outage to concluding a project. Equip yourself with the skills needed to handle your generator effectively and enjoy uninterrupted power whenever you need it.

References

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

- Stabilization of two electricity generators