In the realm of portable generators, the quest for optimal performance often begins with a fundamental question: What type of oil for portable generator? Navigating through the myriad of options can be overwhelming, but fear not, as we embark on a journey to demystify this essential choice. Just as engines have unique personalities, so do the oils that power them. Imagine selecting the perfect elixir for your generator, ensuring a harmonious blend that not only ignites seamless functionality but also prolongs the life of your trusty companion.

Join us in unraveling the nuances of generator lubrication, unlocking the secret to an enduring power partnership.

Jump to a Specific Section

- 1 Core Insights

- 2 What is Generator Oil?

- 3 How Does Oil Impact Engine Performance and Longevity?

- 4 What Type of Oil for Portable Generator?

- 5 Why is Selecting the Right Oil Crucial for a Portable Generator?

- 6 How to Choose the Best Oil for Your Generator?

- 7 What Role Does Oil Viscosity Play in Generator Engines?

- 8 Synthetic Vs. Conventional Oil

- 9 Impact of Fuel Type on the Oil Requirements of a Generator

- 10 How Often Should You Change Oil?

- 11 What Signs Indicate the Need for an Oil Change in a Generator?

- 12 How to Change Oil in a Generator?

- 13 How to Check and Maintain Oil Levels in Your Portable Generator?

- 14 Common Mistakes to Avoid When Using Oil in Portable Generators

- 15 Tips to Extend the Life of a Portable Generator

- 16 Conclusion

- 17 References

- 18 Frequently Asked Questions

- 18.1 Can I Use Regular Motor Oil in My Portable Generator?

- 18.2 How Often Should I Change the Oil in My Portable Generator?

- 18.3 Can I Mix Different Types of Oil in My Generator?

- 18.4 Can I Use Synthetic Oil in My Portable Generator?

- 18.5 What Are the Signs of Low Oil in a Portable Generator?

- 18.6 What kind of oil do you put in a portable generator?

- 18.7 Can you use 10W-30 oil in a generator?

- 18.8 Which oil is used in a generator?

Core Insights

- For a portable generator, it’s typically recommended to use 10W-30 or 10W-40 oil, depending on the manufacturer’s specifications and the temperature conditions.

- Regular maintenance and choosing the right oil brand are crucial for optimal performance and longevity of a portable generator.

- Synthetic oil offers superior lubrication and stability at high temperatures, while conventional oil has a shorter lifespan and is less resistant to breakdown.

- Recommended viscosity range ensures proper lubrication and protection, reducing friction, heat generation, and internal resistance.

- The frequency of oil changes depends on operating hours, ambient conditions, and manufacturer recommendations, with high-quality oils designed for small engines potentially extending the time between changes.

What is Generator Oil?

Generator oil is a crucial component in ensuring the optimal performance and longevity of power generators. It is specifically formulated to meet the demanding requirements of generator engines, providing lubrication to reduce friction, heat, and wear.

High-quality generator oil offers excellent oxidation resistance, maintaining stability under varying temperatures. It also contains additives that deter contaminants and prevent sludge buildup. Using the right generator oil is paramount for smooth operation and protecting the engine from premature wear and damage.

How Does Oil Impact Engine Performance and Longevity?

Understanding the intricate dynamics of generator engines necessitates a closer look at the integral role of oil in shaping their performance and longevity. This symbiotic relationship between oil and engines is far from happenstance; it stands as a fundamental determinant of the overall efficiency and lifespan of these essential power sources.

Lubrication emerges as a linchpin for operational vitality. The application of high-quality oil ensures the smooth movement of various engine components, curbing friction and mitigating wear and tear. This becomes especially critical during demanding periods, such as prolonged operation during power outages or peak usage times.

Beyond facilitating smooth operation, oil in generator engines assumes a crucial responsibility in heat dissipation. As engines function, they generate substantial heat, and the presence of well-formulated oil is instrumental in absorbing and transferring this heat away from vital components. Effective heat management emerges as a cornerstone for engine integrity and longevity.

Another imperative role that oil undertakes is contaminant control. Acting as a protective barrier, oil traps and contains dirt, debris, and other particles that could compromise engine functionality. This defensive function is paramount in preserving the generator’s performance and extending its operational lifespan.

The maintenance of seals and gaskets stands out as a pivotal facet of generator engine longevity, and quality oil plays a key role in this arena. By supporting the integrity of seals, oil prevents leaks and ensures the engine remains impervious to external elements. This preventative measure is integral to warding off internal damage and maintaining consistent performance.

Consider a scenario where a generator operates in an industrial setting, facing continuous demands and environmental stressors. In the absence of diligent oil maintenance, the engine becomes susceptible to heightened friction, heat accumulation, and contaminants, leading to a curtailed lifespan and frequent breakdowns. Conversely, a well-lubricated engine is better poised to confront these challenges, ensuring sustained performance and durability.

In summary, the role of oil in the performance and longevity of generator engines is profound. It acts as a proactive guardian, shielding the engine against the rigors of operation and environmental factors, thereby contributing significantly to the reliability and extended life of these indispensable power sources.

What Type of Oil for Portable Generator?

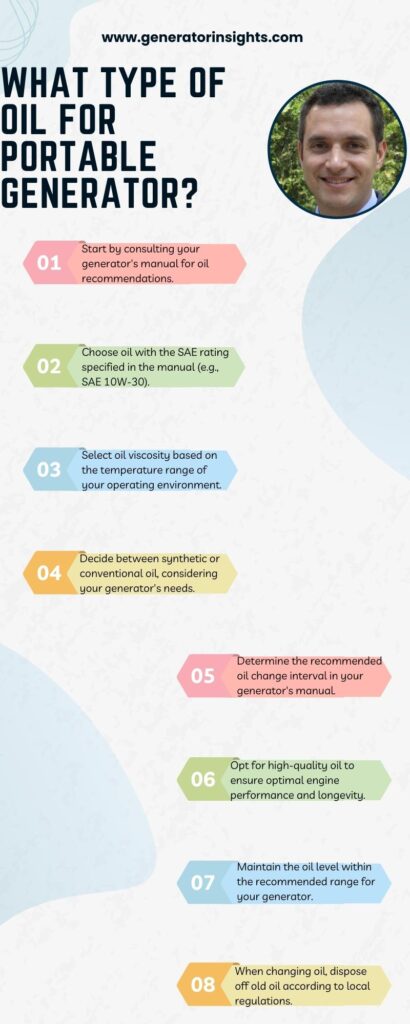

When it comes to maintaining your portable generator, selecting the right oil is crucial for optimal performance and longevity. Here’s a breakdown of the key factors to consider:

- Understanding Viscosity: Begin by checking your generator’s manual for the recommended viscosity. Typically, generators operate best with a multi-viscosity oil, such as 10W-30. This ensures proper lubrication in both cold and warm conditions.

- API Classification: Look for oils with the appropriate API classification, which indicates the quality and performance level. For most generators, an oil with an API SN rating is suitable.

- Synthetic vs. Conventional: While synthetic oils offer better stability and performance in extreme conditions, conventional oils are often more budget-friendly. Consider the operating conditions and your budget when deciding between synthetic and conventional oils.

- Additives for Enhanced Protection: Opt for oils with added anti-wear additives and detergents. These components help keep the engine clean and provide extra protection against wear, corrosion, and deposit buildup.

- Example: If your portable generator operates in cold climates, a synthetic oil like Mobil 1 10W-30, meeting API SN standards, can offer excellent cold-weather performance and overall protection.

By paying attention to these factors, you’ll ensure that your portable generator runs smoothly and remains reliable when you need it most.

Why is Selecting the Right Oil Crucial for a Portable Generator?

Selecting the right oil for your portable generator is crucial for ensuring optimal performance and longevity. The type of oil you choose directly impacts the generator’s efficiency, durability, and overall functionality. Let’s delve into the key reasons why this decision is of utmost importance.

- Engine Protection: Using the appropriate oil ensures proper lubrication, preventing friction and wear on the generator’s engine components. This safeguards against premature breakdowns and extends the generator’s lifespan.

- Temperature Regulation: The right oil helps in managing the generator’s operating temperature. Synthetic oils, for instance, excel in extreme temperatures, providing stability and ensuring reliable performance in both hot and cold conditions.

- Fuel Efficiency: Opting for the correct oil improves the generator’s fuel efficiency. High-quality oils, designed for specific engine types, enhance combustion and reduce fuel consumption, ultimately saving costs in the long run.

- Ease of Starting: The viscosity of the oil is crucial for easy starting, especially in cold weather. Choosing an oil with the right viscosity ensures smooth starts, preventing strain on the generator’s starter and electrical components.

- Reduced Deposits and Contaminants: Quality oils contain additives that help minimize deposits and contaminants in the engine. This, in turn, reduces the risk of clogs, improves overall engine cleanliness, and maintains consistent power output.

- For example, if you have a small gasoline-powered generator, selecting a multi-viscosity oil with an API rating suitable for small engines, like SAE 10W-30, can provide the necessary protection across a range of temperatures and usage conditions.

Ensuring you choose the correct oil for your portable generator is a simple yet crucial step in guaranteeing its reliability and longevity.

How to Choose the Best Oil for Your Generator?

Choosing the right oil for your generator is crucial for ensuring optimal performance and longevity. Various factors come into play when making this decision, and understanding them is essential for generator maintenance.

1. Oil Viscosity: Consider the viscosity of the oil, which determines its thickness. Different generators require different viscosities for optimal operation. Check your generator’s manual for the recommended viscosity range.

2. API Classification: Look for the API (American Petroleum Institute) classification of the oil. It indicates the performance level and is crucial for ensuring compatibility with your generator. Select oil with the appropriate API classification recommended by the generator manufacturer.

3. Additives: Examine the additives in the oil, such as detergents and anti-wear agents. These additives play a vital role in preventing deposits, reducing friction, and enhancing overall engine protection. Opt for oils with high-quality additives.

4. Synthetic vs. Conventional: Decide between synthetic and conventional oils. Synthetic oils offer better temperature stability and longer change intervals, but they can be more expensive. Evaluate your budget and the specific requirements of your generator.

5. Temperature Range: Consider the temperature range in your location. Generators in cold climates may require oil with better cold-start properties, while those in hot climates may need oil with enhanced heat resistance. Choose oil that suits your local climate conditions.

6. OEM Recommendations: Refer to the generator manufacturer’s recommendations. The OEM (Original Equipment Manufacturer) often provides specific guidelines on the type and brand of oil that best suits their generators. Adhering to these recommendations ensures compatibility and performance.

7. Fuel Type: Take into account the fuel type your generator uses. Diesel and gasoline engines may have different oil requirements. Ensure that the chosen oil is compatible with the specific fuel your generator utilizes.

8. Change Intervals: Consider the recommended oil change intervals. Some oils may offer extended change intervals, reducing maintenance frequency. Evaluate your preferences and the manufacturer’s guidelines for an oil change schedule that suits your needs.

9. Storage Conditions: Factor in the storage conditions of your generator. If your generator is stored for extended periods without use, consider oils with anti-corrosion properties to protect the engine during storage.

10. Budget Constraints: Be mindful of your budget constraints. While high-quality oils may offer superior performance, it’s essential to balance performance with affordability. Choose an oil that meets your generator’s requirements without stretching your budget too thin.

By carefully considering these factors, you can make an informed decision when choosing the right oil for your generator, promoting its efficiency and longevity.

What Role Does Oil Viscosity Play in Generator Engines?

Viscosity, denoting the oil’s thickness or resistance to flow, is classified into different grades, typically represented by numerical values.

The Society of Automotive Engineers (SAE) assigns numerical values to denote viscosity grades, illustrating the oil’s flow characteristics at different temperatures. A common SAE value might be 10W-30, where the ’10W’ indicates its flow in winter (low temperatures) and ’30’ signifies viscosity at operating temperatures.

Impact on Engine Lubrication: Maintaining the ideal oil viscosity is pivotal for effective engine lubrication. Consider a generator operating with an SAE 10W-30 oil. In colder conditions, the oil’s thinner consistency facilitates smooth startup lubrication. As the engine warms up, the viscosity thickens, providing a robust lubricating film, minimizing friction, and preventing wear between engine components.

Temperature Sensitivity: Temperature fluctuations underscore the importance of choosing the right viscosity grade. An SAE 5W-40 oil, for instance, is well-suited for generators experiencing a broad temperature range. Its low-temperature viscosity ensures easy engine cranking in colder climates, while the higher operating temperature viscosity maintains stable lubrication under heat stress.

Synthetic Vs. Conventional Oil

Choosing the right type of oil for your portable generator is crucial to ensure optimal performance and longevity. In this comparison, we’ll delve into the differences between synthetic and conventional oil for portable generators, helping you make an informed decision for your power equipment.

| Criteria | Synthetic Oil | Conventional Oil |

|---|---|---|

| Composition | Crafted from chemically modified base oils | Derived from crude oil through traditional refining processes |

| Purity and Consistency | Boasts uniform molecular structure, reducing impurities | May contain impurities due to the refining process |

| Temperature Performance | Maintains consistent viscosity across a broad temperature range | Viscosity can vary with temperature fluctuations |

| Engine Protection | Offers enhanced protection against wear and deposits | Provides basic protection for engine components |

| Cold-Weather Performance | Flows smoothly in cold temperatures, ensuring easy starts | Cold temperatures may cause thicker oil, leading to potential starting issues |

| Heat Resistance | Exhibits improved stability at high temperatures | May break down more quickly under extreme heat |

| Extended Drain Intervals | Allows for longer oil change intervals due to superior stability | Requires more frequent oil changes |

| Cost | Generally comes with a higher price tag | More budget-friendly option |

Impact of Fuel Type on the Oil Requirements of a Generator

When considering the impact of fuel type on the oil requirements of a generator, it’s crucial to recognize the significant role that proper lubrication plays in the longevity and performance of the equipment. The choice of fuel directly influences the characteristics of the oil needed to maintain optimal functionality.

Gasoline-powered generators, for instance, often require a specific type of oil tailored to the engine’s demands. Typically, these generators operate on a four-stroke engine, necessitating an oil that provides both lubrication and cooling. It’s recommended to use a high-quality SAE 10W-30 oil for such generators, ensuring proper viscosity in varied temperature conditions.

On the other hand, diesel generators have distinct oil requirements due to differences in engine design and combustion characteristics. Diesel engines operate at higher temperatures and generally demand oils with higher viscosity to withstand the additional heat generated. An SAE 15W-40 oil is a common choice for diesel generators, offering enhanced protection under the elevated operating temperatures.

Understanding the specific needs of your generator based on its fuel type is essential in selecting the right oil for optimal performance and durability. Always refer to the manufacturer’s guidelines for the recommended oil specifications, as using the wrong type of oil can result in inefficient operation and potential long-term damage to the generator.

How Often Should You Change Oil?

Regular oil changes are crucial for maintaining the efficiency and longevity of your generator. The frequency of oil changes depends on factors like the type of oil used, usage patterns, and manufacturer recommendations.

For most generators, a general guideline is to change the oil every 100-200 hours of operation or at least once a year. This routine maintenance ensures proper lubrication and helps prevent potential issues.

Generators experiencing heavy or continuous usage may require more frequent oil changes. Regular inspections and monitoring oil quality become essential in such cases to ensure optimal performance.

The choice of oil is critical. Refer to the generator’s manual for recommended oil specifications. Using high-quality synthetic oil can extend change intervals and contribute to better overall performance.

Thus, a consistent oil change schedule tailored to your generator’s usage and the quality of oil used is essential for reliability and longevity. Always follow manufacturer guidelines and, when uncertain, consult with a professional for personalized advice.

What Signs Indicate the Need for an Oil Change in a Generator?

Regular maintenance, especially oil changes, is crucial for ensuring the optimal performance and longevity of a generator. Ignoring the signs that indicate the need for an oil change can lead to severe damage and costly repairs. Keep a vigilant eye on the following indicators to determine when it’s time to change the oil in your generator:

| Signs | Indication |

|---|---|

| 1. Oil Color: | If you notice that the oil color has turned dark and opaque, it may indicate contamination or degradation, signaling a need for an oil change. |

| 2. Oil Level: | A sudden drop in the oil level on the dipstick suggests a potential leak or consumption, underscoring the necessity for a timely oil change. |

| 3. Engine Noise: | Unusual engine noises, such as increased knocking or clattering, can signify insufficient lubrication, highlighting the urgency for an oil change. |

| 4. Increased Temperature: | Elevated operating temperatures may point to the oil’s diminished ability to dissipate heat, emphasizing the importance of a fresh oil change to maintain proper engine cooling. |

| 5. Poor Generator Performance: | Decreased power output or inefficient generator performance may be indicative of compromised lubrication, necessitating a prompt oil change to restore optimal functionality. |

| 6. Manufacturer Recommendations: | Adhering to the manufacturer’s recommended oil change intervals is crucial to ensure the generator operates at peak efficiency and longevity. Regular maintenance is key for optimal performance. |

Regularly monitoring these signs and addressing them promptly through an oil change will contribute to the longevity and reliability of your generator.

How to Change Oil in a Generator?

Regularly changing the oil in your generator is crucial for maintaining its optimal performance and extending its lifespan. This step-by-step guide will walk you through the process, ensuring that you can efficiently change the oil in your generator without any hassle.

Step 1: Gather Necessary Tools and Materials

- Materials needed: New generator oil, oil filter, oil pan, funnel.

- Tools required: Wrench, oil filter wrench, rag.

Step 2: Turn Off the Generator

- Ensure the generator is powered down completely.

- Let it cool down for a few minutes to prevent burns.

Step 3: Locate the Oil Drain Plug

- Refer to the generator’s manual to find the exact location of the oil drain plug.

- Typically, it is on the lower part of the engine.

Step 4: Place the Oil Pan

- Position the oil pan beneath the oil drain plug to catch the used oil.

Step 5: Remove the Oil Drain Plug

- Use a wrench to loosen the oil drain plug.

- Unscrew it carefully, allowing the old oil to drain into the pan.

Step 6: Remove the Oil Filter

- Use an oil filter wrench to remove the old oil filter.

- Be prepared for some additional oil to drip.

Step 7: Prepare the New Oil Filter

- Apply a small amount of new oil to the rubber gasket of the new oil filter.

- This helps with a smoother installation.

Step 8: Install the New Oil Filter

- Hand-tighten the new oil filter onto the generator.

- Use the oil filter wrench for an additional half turn to ensure a snug fit.

Step 9: Replace the Oil Drain Plug

- Once the old oil has drained completely, screw in the oil drain plug securely.

Step 10: Add New Oil

- Using a funnel, pour the recommended amount of new oil into the oil fill cap.

- Check the manual for the correct oil type and capacity.

Step 11: Check the Oil Level

- Start the generator and let it run for a few minutes.

- Check the oil level and add more if necessary.

Step 12: Dispose of Used Oil

- Properly dispose of the used oil at a local recycling center or an auto parts store.

By following these steps, you’ll ensure that your generator is running smoothly with fresh oil, contributing to its overall longevity and performance.

How to Check and Maintain Oil Levels in Your Portable Generator?

Ensuring proper oil levels in your portable generator is crucial for its optimal performance and longevity. Regular maintenance plays a key role in preventing damage and ensuring a reliable power source. Follow these steps to learn how to check and maintain oil levels in your portable generator.

- Locate the Oil Dipstick:

- Identify the oil dipstick on your generator. It is typically located near the engine and may have a bright color for easy recognition.

- Run the Generator for a Few Minutes:

- Start the generator and let it run for a few minutes. This helps to warm up the oil, making it easier to check accurately.

- Turn Off the Generator:

- Switch off the generator and allow it to cool down for a couple of minutes before proceeding.

- Remove the Oil Dipstick:

- Pull out the oil dipstick and wipe it clean with a cloth. This ensures an accurate reading.

- Check the Oil Level:

- Reinsert the dipstick fully, then pull it out again. Inspect the oil level on the dipstick. There are usually markings indicating the appropriate oil level range.

- Top Up if Necessary:

- If the oil level is below the recommended range, add the appropriate oil for your generator. Refer to the user manual for the correct oil type.

- Avoid Overfilling:

- It’s crucial not to overfill the oil. Check the level periodically during the filling process to avoid exceeding the recommended capacity.

- Repeat Regularly:

- Perform this check regularly, especially before extended use or during heavy-duty operations.

Common Mistakes to Avoid When Using Oil in Portable Generators

Portable generators are a convenient power solution, but ensuring their optimal performance requires proper care, especially when it comes to oil maintenance. Choosing the right oil and using it correctly can significantly impact the generator’s efficiency and lifespan. Here are some common mistakes to steer clear of:

| Mistake | Description |

|---|---|

| Using the Wrong Oil Grade | Choosing the appropriate oil grade is crucial. Using an oil with a viscosity that doesn’t match the generator’s specifications can lead to increased friction, reduced efficiency, and potential damage over time. Always refer to the manufacturer’s guidelines for the correct oil grade. |

| Neglecting Regular Oil Checks | Regularly monitoring the oil level and quality is essential. Neglecting this aspect may result in insufficient lubrication, causing excessive wear on engine components. Perform routine checks and adhere to recommended oil change intervals to keep the generator running smoothly. |

| Overfilling the Oil Reservoir | Overfilling the oil reservoir can be as detrimental as having too little oil. It can lead to increased pressure, compromising the engine’s seals and gaskets, potentially causing leaks and reducing overall performance. Follow the manufacturer’s recommendations for the correct oil capacity. |

| Ignoring Oil Change Intervals | Frequent oil changes are imperative for maintaining generator health. Ignoring the recommended intervals can result in the accumulation of contaminants and debris in the oil, leading to decreased lubrication effectiveness and increased friction. Regularly change the oil as per the manufacturer’s guidelines. |

| Using Contaminated Oil | Contaminated oil can harm the generator’s engine. Ensure that the oil used is clean and free from impurities. Contaminants can cause abrasive damage to internal components, reducing the generator’s efficiency and lifespan. Always store oil in sealed containers and use a clean funnel for refilling. |

By avoiding these common mistakes, you can enhance the performance and longevity of your portable generator, ensuring a reliable power source when you need it most.

Tips to Extend the Life of a Portable Generator

- Regular Maintenance: Ensure your portable generator operates efficiently by conducting routine maintenance, including oil changes, filter replacements, and spark plug checks.

- Proper Storage: Store your generator in a cool, dry place to prevent rust and corrosion. Avoid exposure to extreme temperatures that can degrade its components.

- Fuel Quality: Use high-quality, stabilized fuel to prevent clogs and engine issues. Empty the fuel tank before long periods of inactivity to avoid fuel deterioration.

- Airflow Consideration: Place your generator in a well-ventilated area to prevent overheating. Clear any debris or obstructions around the generator’s air vents.

- Run at Optimal Load: Running your generator at 50-75% of its maximum load enhances fuel efficiency and reduces wear and tear on the engine. Avoid constant low-load operation.

- Cool Down Periods: Allow your generator to cool down before shutting it off completely. This prevents damage to internal components and extends the overall lifespan.

- Invest in Voltage Regulators: Voltage fluctuations can damage sensitive electronics. Consider using a voltage regulator or stabilizer to maintain a consistent power output.

- Regular Exercise: Start and run your generator periodically, even if not in use, to lubricate moving parts and prevent the fuel system from clogging.

- Protect Against Moisture: Moisture can lead to electrical issues and corrosion. Use generator covers or enclosures to shield it from rain and humidity.

- Professional Inspection: Schedule a professional inspection at least once a year to identify potential problems early on and ensure all components are functioning correctly.

Remember, implementing these tips for extending the life of your portable generator can save you money on repairs and provide reliable power when you need it most.

Conclusion

We conclude what type of oil for portable generator on the note that the choice of oil for your portable generator plays a pivotal role in its performance and longevity. Selecting the right oil type, considering factors like viscosity and climate, ensures that your generator runs efficiently and remains reliable during power outages. Regular oil changes and proper maintenance are essential to keep your generator in top condition.

As you navigate the world of generator ownership, let this guide be your trusted resource, offering insights into the importance of choosing the right oil. With the right oil and proper care, your portable generator will stand ready to provide you with the power you need, whenever you need it.

References

- Linear electric actuators and generators

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

Frequently Asked Questions

Can I Use Regular Motor Oil in My Portable Generator?

Using motor oil in a generator has both pros and cons. Pros include availability and cost-effectiveness, while cons involve potential damage to the generator due to inadequate lubrication properties.

How Often Should I Change the Oil in My Portable Generator?

Determining the appropriate oil for a portable generator and establishing an oil change schedule are essential for maintaining optimal performance. Additionally, knowing how to properly dispose of used oil is crucial for environmental responsibility.

Can I Mix Different Types of Oil in My Generator?

Mixing different types of oil in a generator may result in unpredictable oil viscosity, which can adversely affect engine performance. It is advisable to use the recommended type and grade of oil specified by the manufacturer for optimal functioning.

Can I Use Synthetic Oil in My Portable Generator?

The use of synthetic oil in portable generators has its benefits, but also comes with pros and cons. Synthetic oil offers improved lubrication and thermal stability, but it is generally more expensive than conventional oils.

What Are the Signs of Low Oil in a Portable Generator?

Common causes of low oil in a portable generator include leaks, improper maintenance, and prolonged use without replenishing. Regularly checking oil levels is important to prevent engine damage and ensure optimal performance.

What kind of oil do you put in a portable generator?

Commonly used oils for generators include SAE 10W-30, suitable for most generators, and SAE 5W-30, recommended for colder temperatures or winter use.

Can you use 10W-30 oil in a generator?

Yes, 10W-30 generator oil is recommended for all RV gasoline generators, formulated for severe temperatures. Its 10W viscosity at low temperatures allows it to replace conventional SAE 30 oils in RV gasoline generators.

Which oil is used in a generator?

Generator Set Oil 20w-40 is recommended as crankcase oil for slow, medium, and high-speed stationary diesel engines like Generator Set Oil. It is suitable for all conditions and effectively reduces oil consumption.