In the world of small generators, choosing the right oil is like giving your trusty companion the perfect elixir for peak performance. What type of oil do small generators use? becomes a pivotal question, unlocking the secret to longevity and efficiency.

Picture this: your generator humming in sync with your needs, a seamless dance of power and reliability. Just as athletes rely on the right fuel for optimal results, these compact powerhouses crave a specific oil blend. Let’s embark on a journey where the heartbeat of your generator meets the lifeline of the perfect oil, ensuring a harmonious symphony of power when you need it most.

Jump to a Specific Section

- 1 Key Points

- 2 What is the Need for Generator Oil?

- 3 What Type of Oil Do Small Generators Use?

- 4 Can We Run Generator Without Oil?

- 5 What are Different Types of Generator Oils?

- 6 Conventional vs Synthetic Generator Oil

- 7 How to Choose the Right Oil for Your Generator?

- 8 How Often Should you Change Generator Oil?

- 9 How to Change Generator Oil?

- 10 Troubleshooting Common Generator Issues

- 11 Finding the Right Generator Oil Supplier

- 12 Conclusion

- 13 References

- 14 Frequently Asked Questions

- 14.1 How Often Should I Change the Oil in My Generator?

- 14.2 What Is the Best Type of Oil for a Small Generator?

- 14.3 Are There Any Special Safety Precautions I Should Take When Using Generator Oil?

- 14.4 What Is the Difference Between Synthetic and Regular Generator Oil?

- 14.5 How Do I Know When It’s Time to Replace My Generator Oil?

- 14.6 What kind of oil do you put in a small generator?

- 14.7 Can you use 10W30 oil in a generator?

- 14.8 Do you use regular or synthetic oil in a portable generator?

Key Points

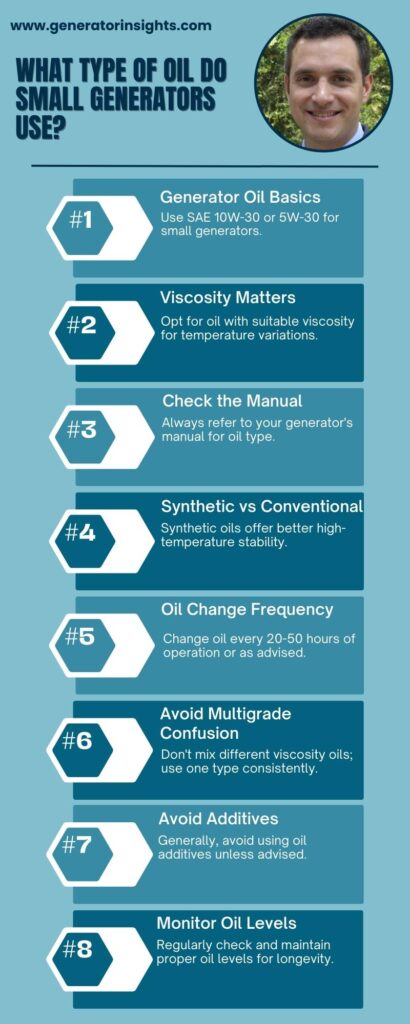

- Oil Type for Small Generators: Small generators typically use 10W-30 motor oil, chosen for its versatility in different temperature ranges.

- Versatile Lubrication: 10W-30 oil provides effective lubrication during startup, even in colder conditions, and maintains its performance as the engine warms up.

- Good Flow Properties: The oil’s good flow properties ensure that engine components receive proper lubrication, contributing to efficient generator operation.

- Consult Manual for Specifics: It’s crucial to consult the generator’s manual for oil recommendations, as different models may have specific requirements based on design and use, emphasizing the importance of regular oil checks and changes.

What is the Need for Generator Oil?

Generators play a critical role in providing backup power during outages, emergencies, or in areas where a stable power supply is not readily available. One of the key components ensuring the smooth operation and longevity of a generator is the use of generator oil. Here’s a detailed breakdown of the need for generator oil:

1. Lubrication of Engine Components:

A generator’s engine consists of numerous moving parts that operate at high speeds and under considerable stress. Generator oil serves as a lubricant to reduce friction between these components. Proper lubrication is essential for preventing wear and tear, minimizing heat buildup, and ensuring the efficient functioning of the engine.

2. Heat Dissipation:

Generators, especially those used for prolonged periods or in demanding conditions, generate a significant amount of heat during operation. Generator oil aids in dissipating this heat, preventing the engine from overheating. Effective heat dissipation is crucial for maintaining the structural integrity of engine components and avoiding potential damage due to excessive temperatures.

3. Sealant and Corrosion Protection:

Generator oil acts as a sealant, creating a barrier between various engine parts. This barrier helps prevent the entry of contaminants, such as dust and dirt, into the engine. Additionally, the oil provides a protective layer that guards against corrosion and rust, particularly in areas with high humidity or when the generator is not in use for extended periods.

4. Cleaning and Particle Suspension:

Generator oil plays a vital role in trapping and suspending particles and debris that may find their way into the engine. This prevents these particles from settling on engine components and causing damage. The oil’s detergent properties contribute to maintaining a cleaner engine, promoting overall efficiency and longevity.

5. Enhanced Performance and Fuel Efficiency:

Properly selected and regularly changed generator oil contributes to enhanced engine performance and fuel efficiency. Clean oil reduces friction, allowing the engine to operate smoothly and efficiently. This, in turn, can lead to fuel savings and a more reliable power supply.

6. Prolonged Engine Life:

Regular maintenance, including the use of high-quality oil, is crucial for extending the life of a generator. The continuous and effective lubrication provided by the oil helps prevent premature wear and extends the overall lifespan of the engine. This is particularly important for those relying on generators for continuous or critical power needs.

What Type of Oil Do Small Generators Use?

Small generators typically use a 10W-30 motor oil. This oil type is commonly recommended for small engines due to its versatility in various temperature ranges. It provides adequate lubrication during startup, even in colder conditions, and maintains its effectiveness as the engine warms up.

Additionally, 10W-30 oil has good flow properties, ensuring that engine components receive proper lubrication. It’s important to consult the generator’s manual for specific oil recommendations, as some models may have different requirements based on their design and intended use. Regular oil checks and changes are crucial to ensure the generator operates efficiently and reliably.

Can We Run Generator Without Oil?

Running a generator without oil is a highly inadvisable and potentially disastrous practice. Oil serves critical functions within the engine, primarily acting as a lubricant for the various moving parts. This lubrication is essential in minimizing friction and preventing overheating, allowing the engine components to operate smoothly and efficiently. Without proper lubrication, friction between these parts increases, leading to rapid wear and potential damage.

Additionally, oil plays a crucial role in the cooling process of the engine. It helps dissipate the heat generated during the combustion of fuel, preventing the engine from reaching excessive temperatures. Operating a generator without oil compromises this cooling mechanism, putting the engine at risk of overheating, warping, and ultimately failing.

The absence of oil also impacts the sealing and compression functions of the engine. Oil creates a seal between the pistons and cylinders, contributing to proper compression. Running a generator without oil can compromise this seal, resulting in decreased efficiency, power loss, and potential engine failure.

The consequences of running a generator without oil extend beyond mechanical issues. The heightened friction and heat generated in the engine due to the lack of lubrication pose a fire hazard. While the combustion process in the engine is designed for controlled burning of fuel, uncontrolled heat resulting from insufficient lubrication can lead to fires.

Repairing or replacing an engine damaged due to the lack of oil can be a costly and, in many cases, impractical endeavor. In addition to the financial implications, neglecting proper oil maintenance typically voids the manufacturer’s warranty. Manufacturers provide specific guidelines for maintenance, including oil changes, and failure to adhere to these recommendations can result in the loss of warranty coverage.

What are Different Types of Generator Oils?

Generators play a crucial role in providing backup power during outages or in remote locations. To ensure the optimal performance and longevity of your generator, selecting the right oil is paramount. Various types of generator oils are available, each designed to meet specific engine requirements. Here’s a detailed guide on the different types of generator oils:

1. Conventional Motor Oil:

Conventional motor oil, often labeled as SAE 30, is a standard option for generators operating in moderate climates. It works well in engines with minimal temperature variations. However, it may not be the best choice for extremely cold or hot environments.

2. Synthetic Motor Oil:

Synthetic oils, available in various viscosity grades, offer superior performance in extreme temperature conditions. They provide better protection against wear, have a longer lifespan, and generally flow more smoothly at low temperatures. Synthetic oils are an excellent choice for generators exposed to temperature fluctuations or operating in challenging environments.

3. Multi-Viscosity Oil:

Multi-viscosity oils, such as 10W-30 or 5W-30, are designed to provide effective lubrication across a range of temperatures. The “W” stands for winter, indicating the oil’s performance in cold conditions. These oils are versatile and suitable for generators used in regions with varying climates.

4. High Mileage Oil:

If your generator has been in use for an extended period, high mileage oils may be a suitable choice. They often contain additives that help condition seals and reduce oil consumption. High mileage oils can be beneficial for older generators with well-worn components.

5. Synthetic Blend Oil:

A blend of conventional and synthetic oils, synthetic blends offer a middle ground in terms of performance and cost. They provide better protection than conventional oils and are more affordable than full synthetic options. Synthetic blends are a good compromise for generators that need enhanced protection without the cost of pure synthetic oil.

6. Two-Stroke Oil:

For generators with two-stroke engines, two-stroke oil is essential. It is designed to be mixed with fuel in specific ratios to provide lubrication to the engine. It is crucial to follow the manufacturer’s recommendations regarding the correct oil-to-fuel ratio for optimal performance.

7. Diesel Engine Oil:

Generators with diesel engines require specific diesel engine oil. These oils are formulated to handle the higher temperatures and increased stress associated with diesel engines. They often contain additives to control soot, manage deposits, and enhance overall engine performance.

8. Natural Gas Engine Oil:

Generators powered by natural gas or propane have unique lubrication requirements. Natural gas engine oils are formulated to address the characteristics of gaseous fuels and provide reliable protection for engines operating on these fuels.

Conventional vs Synthetic Generator Oil

| Aspect | Conventional Oil | Synthetic Oil |

|---|---|---|

| Base Oil Composition | Derived from crude oil | Chemically engineered using a base of artificially synthesized molecules |

| Molecular Structure | Irregular and varied molecular structure | Uniform and consistent molecular structure |

| Viscosity Stability | Varies with temperature; may break down at high heat | Stable viscosity across a wide temperature range; maintains effectiveness at high temperatures |

| Temperature Tolerance | More prone to thinning at high temperatures | Maintains viscosity and stability in extreme temperature conditions |

| Cold Weather Performance | Thickens in cold temperatures, leading to poor flow | Maintains fluidity in cold weather, ensuring quick and efficient startup |

| Oxidation Resistance | More susceptible to oxidation and degradation over time | Resistant to oxidation, resulting in a longer oil life |

| Price | Generally less expensive | Higher initial cost, but potential for longer change intervals may offset cost |

| Change Intervals | Typically requires more frequent oil changes | Allows for extended change intervals due to superior stability |

| Engine Protection | Provides basic protection for the engine | Offers enhanced protection, especially in high-stress and high-temperature conditions |

| Recommended Use | Suitable for standard operating conditions and budget-conscious consumers | Ideal for high-performance generators, frequent use, and those operating in extreme conditions |

It’s important to note that the choice between conventional and synthetic oil depends on various factors, including the generator’s specifications, operating conditions, and the owner’s maintenance preferences. Always refer to the manufacturer’s recommendations for the most suitable oil for your specific generator model.

How to Choose the Right Oil for Your Generator?

Following are some important considerations for choosing the right oil for your generator:

- Check the Manufacturer’s Recommendations:

- Refer to your generator’s user manual for specific guidelines on the recommended oil type. Manufacturers provide precise information regarding oil viscosity and quality.

- Consider the Climate and Temperature:

- Choose oil viscosity based on the climate in which your generator will operate. In colder climates, a lower viscosity oil (e.g., 5W-30) is preferable, while hotter climates may require a higher viscosity oil (e.g., 10W-30 or 10W-40).

- API Classification:

- Look for oil with the right American Petroleum Institute (API) classification. Common classifications include SJ, SL, SM, or SN. The higher the letter, the newer and more advanced the oil formulation.

- Synthetic vs. Conventional Oils:

- Synthetic oils generally offer better performance in extreme temperatures and provide enhanced protection for your generator’s engine. However, they are often more expensive than conventional oils.

- Brand Reputation:

- Opt for oils from reputable brands with a history of producing high-quality lubricants. Well-known brands often invest in research and development to create oils that meet or exceed industry standards.

- Detergent or Non-Detergent Oil:

- Most modern generators require detergent oil, as it helps keep the engine clean by preventing deposits and sludge. Check your generator’s manual to confirm the recommended oil type.

- Oil Change Intervals:

- Consider the recommended oil change intervals provided by the generator’s manufacturer. Some generators may require more frequent oil changes, especially during heavy usage or extreme conditions.

- Container Size and Packaging:

- Choose an oil container size that matches the capacity of your generator’s crankcase. Ensure the packaging is sealed and intact to maintain the oil’s quality.

- Multi-Viscosity Oils:

- Multi-viscosity oils (e.g., 10W-30) offer versatility in different temperature conditions. They provide better protection during cold starts while maintaining viscosity at higher temperatures.

- Oil Additives:

- Avoid adding aftermarket oil additives unless recommended by the generator manufacturer. Some additives may adversely affect the oil’s composition and the engine’s performance.

- Check for Regulatory Approvals:

- Look for oils that meet industry standards and have relevant certifications, such as those from the American Petroleum Institute (API) and the International Lubricant Standardization and Approval Committee (ILSAC).

Choosing the right oil for your generator is essential for maintaining optimal performance and extending the lifespan of your equipment. Always refer to your generator’s manual for specific recommendations and guidelines.

How Often Should you Change Generator Oil?

Regular maintenance, including oil changes, is crucial to ensure the optimal performance and longevity of your generator. The frequency at which you should change the oil in your generator depends on several factors, including the type of generator, its usage, and the operating conditions. Here’s a detailed guide to help you determine how often you should change your generator oil:

1. Manufacturer’s Recommendations:

The first and most important source of information is the manufacturer’s guidelines. Refer to your generator’s user manual for specific recommendations regarding oil change intervals. Manufacturers often provide detailed instructions on maintenance schedules, including the recommended type of oil and the number of hours or months between oil changes.

2. Usage Frequency:

Generators used more frequently will require more frequent oil changes. If your generator operates for extended periods or is used regularly, you may need to change the oil more often. For generators used in emergency situations or as a primary power source, consider more frequent oil changes to maintain optimal performance.

3. Operating Conditions:

The environment in which your generator operates also affects the frequency of oil changes. If your generator operates in extreme temperatures, such as very hot or very cold conditions, it may require more frequent oil changes. High temperatures can break down oil more quickly, while cold temperatures can lead to oil thickening.

4. Oil Type:

The type of oil you use in your generator plays a role in determining the frequency of oil changes. Some generators use conventional oil, while others may require synthetic oil. Synthetic oils generally have a longer lifespan and can withstand higher temperatures, which may allow for extended oil change intervals. However, always follow the manufacturer’s recommendations regarding oil type and change intervals.

5. Hourly or Monthly Intervals:

As a general guideline, many generator manufacturers recommend changing the oil every 50 to 100 operating hours or at least once a year, even if the generator hasn’t been used extensively. This is a good rule of thumb for standard maintenance.

6. Regular Inspections:

In addition to regular oil changes, it’s essential to inspect the oil level and condition regularly. Check for any signs of contamination, such as metal particles or a milky appearance, which could indicate a problem with the generator.

How to Change Generator Oil?

- Gather the Necessary Tools and Materials:

- Wrench set

- Oil drain pan

- Funnel

- New oil (as per manufacturer’s specifications)

- Oil filter (if applicable)

- Shop towels or rags

- Safety First:

- Ensure the generator is turned off and cooled down.

- Put on safety goggles and gloves to protect yourself from oil and debris.

- Locate the Oil Drain Plug:

- Consult the generator’s user manual to identify the location of the oil drain plug. It is typically located at the bottom of the engine.

- Position the Generator:

- Place the generator on a level surface to ensure proper drainage of the oil.

- Remove the Oil Fill Cap:

- Unscrew the oil fill cap to allow air to enter the system, facilitating smoother oil drainage.

- Place the Oil Drain Pan:

- Position the oil drain pan under the oil drain plug to catch the used oil.

- Loosen and Remove the Drain Plug:

- Use the appropriate wrench to loosen and remove the oil drain plug. Allow the used oil to drain completely into the pan.

- Remove and Replace the Oil Filter (if applicable):

- If your generator has an oil filter, use an oil filter wrench to remove it. Replace it with a new filter, ensuring it’s properly tightened.

- Drain the Oil Completely:

- Allow the oil to drain completely, ensuring that no residual oil remains in the engine.

- Install the Oil Drain Plug:

- Once the oil has drained, reinstall the oil drain plug and tighten it securely.

- Add New Oil:

- Use a funnel to pour the recommended amount and type of new oil into the oil fill opening.

- Check the Oil Level:

- Start the generator and let it run for a few minutes. Then, turn it off and check the oil level using the dipstick. Add more oil if necessary.

- Dispose of Used Oil Properly:

- Collect the used oil in a suitable container and dispose of it at a recycling center or an authorized oil disposal facility.

- Clean Up:

- Wipe down any spilled oil and ensure that the generator and the surrounding area are clean.

- Record the Maintenance:

- Keep a record of the date and hours of operation when you changed the oil. This helps in scheduling future maintenance.

By following these steps, you can successfully change the oil in your generator, promoting its longevity and ensuring reliable performance when needed. Always refer to the manufacturer’s guidelines for specific instructions related to your generator model.

Troubleshooting Common Generator Issues

When it comes to small generators, like those used for home or recreational purposes, there are certain common issues that can arise. Many of these issues can be traced back to the type and quality of oil being used in the generator. To ensure a properly functioning generator it is important to use oil from reputable brands and check the temperature control regularly.

Inadequate lubrication from sub-standard oil can lead to premature wear and tear on the moving parts of a generator, resulting in decreased performance and even potential damage. Poor temperature control can also cause problems such as overheating which can result in further damage if not detected quickly enough.

Using good quality oil from trusted brands is essential for avoiding these potential problems. Furthermore, checking the temperature control regularly should help prevent any issues arising due to overheating. This combination of using good quality oil and monitoring temperature will help keep your small generator running smoothly for years with minimal maintenance required.

Now that we have discussed troubleshooting common issues related to small generators, let’s move on to finding out how to locate a reliable supplier of generator oils.

Finding the Right Generator Oil Supplier

Identifying an appropriate supplier of generator oils is essential for maintaining the efficient operation of small generators. When looking for a supplier, it is important to consider several factors:

- Power suppliers should have local availability to ensure timely delivery and proactive service.

- They should offer quality, high-performance oils that are specifically designed for small generators.

- Suppliers should provide competitive pricing with flexible payment options.

- Their staff should have extensive experience in the oil industry, as well as knowledge about how different types of oils work best in various generator models.

- Look for suppliers who offer comprehensive support services such as installation assistance and maintenance guidance.

Conclusion

In conclusion, knowing the right type of oil for your small generator is a cornerstone of responsible ownership. By adhering to manufacturer recommendations and considering factors like viscosity and additives, you guarantee the longevity and efficiency of your equipment. Regular oil checks and changes are vital for optimal performance.

As you embark on your generator journey, let this guide serve as your reliable companion, providing you with the knowledge and confidence needed to keep your small generator running smoothly. With the right oil, you’re not just maintaining a machine – you’re ensuring uninterrupted power when you need it most.

References

- Linear electric actuators and generators

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

Frequently Asked Questions

How Often Should I Change the Oil in My Generator?

It is recommended to change the oil in your generator once every six months or after every 50 hours of use, whichever comes first. It is also important to store the oil properly and replace the oil filters when changing the oil. This helps ensure that your generator runs smoothly and safely.

What Is the Best Type of Oil for a Small Generator?

When selecting the best type of oil for a small generator, it is important to consider fuel additives, oil viscosity, and oil filters. This will help ensure optimal performance and longevity of the generator while also providing a sense of belonging to its owner.

Are There Any Special Safety Precautions I Should Take When Using Generator Oil?

When using generator oil, one must exercise extreme caution and take proper safety precautions. These include ensuring proper disposal of the used oil and taking necessary storage precautions to avoid any unfortunate accidents or mishaps. Exercising vigilance with every step can help ensure a safe experience.

What Is the Difference Between Synthetic and Regular Generator Oil?

Regular generator oil is derived from petroleum and requires regular maintenance to ensure efficient engine operation. Synthetic oil offers enhanced performance, improved fuel economy and extended service life compared to regular oil. Synthetic oils also boast a greater resistance to chemical breakdown, oxidation, and thermal degradation for superior longevity.

How Do I Know When It’s Time to Replace My Generator Oil?

Preventive maintenance is key to ensuring optimal generator performance, and replacing the oil and filters regularly is an essential part of this. To know when it’s time to replace the oil, check your owner’s manual for specific instructions, including how often the oil should be changed.

What kind of oil do you put in a small generator?

Commonly used oils for small generators include SAE 10W-30, suitable for most generators, and SAE 5W-30, recommended for colder temperatures or winter use.

Can you use 10W30 oil in a generator?

Yes, 10W-30 generator oil is recommended for RV gasoline generators, providing protection in severe temperatures. Its 10W viscosity at low temperatures allows it to replace conventional SAE 30 oils in RV gasoline generators.

Do you use regular or synthetic oil in a portable generator?

The primary function of oil in your generator is to protect engine parts that come into contact. Synthetic oil offers superior protection compared to cheaper oils, reducing the likelihood of breakdown, making it a beneficial choice for your portable generator.