Embarking on the journey of selecting the right size wire for your portable generator can feel like navigating a maze of technicalities. Amidst the array of options, the pivotal question echoes: What size wire do I need for a portable generator?

Delving into this realm isn’t just about volts and amps; it’s about empowering your space with uninterrupted energy. Picture a scenario where every connection resonates seamlessly, empowering your generator to unleash its full potential. In this guide, we’ll unravel the mystery, ensuring your choice isn’t just about wires; it’s about crafting a power source that aligns perfectly with your needs and aspirations.

Jump to a Specific Section

- 1 Key Points

- 2 What is a Portable Generator?

- 3 How Does a Portable Generator Work?

- 4 What Size Wire Do I Need for a Portable Generator?

- 5 What are Different Types of Wire Gauges for Portable Generator?

- 6 Factors to Consider When Choosing a Wire for Your Portable Generator

- 7 Troubleshooting Common Generator Wiring Issues

- 8 Generator Wiring Safety Tips

- 9 Conclusion

- 10 References

- 11 Frequently Asked Questions

- 11.1 How Do I Ensure My Generator Is Safe to Use?

- 11.2 What Is the Best Way to Install the Wiring for My Generator?

- 11.3 How Do I Know if the Generator Is Compatible With My Home’s Electrical System?

- 11.4 How Can I Determine the Amount of Power My Generator Will Need to Provide?

- 11.5 Is There a Specific Type of Wiring That Should Be Used for a Portable Generator?

- 11.6 What size cable do I need to connect a generator to my house?

- 11.7 What size wire do I need for a 7500 watt generator?

- 11.8 What size wire is needed for a 30 amp generator?

Key Points

- For a 30-amp circuit, a 10 AWG copper conductor is typically recommended.

- Consider power monitoring and alternative power sources

- Calculate amperage requirements based on voltage rating and additional loads

- Select a wire that can handle the current safely

- Follow safety protocols when implementing a portable generator setup

What is a Portable Generator?

Portable generators are typically fueled by gasoline or propane, granting users the flexibility to choose based on their preferences and availability. Their compact size and ease of mobility make them invaluable for camping trips, outdoor events, or as backup power sources for homes.

One of the key advantages of portable generators lies in their plug-and-play simplicity. Users can easily connect essential appliances or devices directly to the generator, ensuring a quick and hassle-free power supply. This feature makes them an essential tool for homeowners, outdoor enthusiasts, and businesses seeking a reliable and convenient energy source in various situations.

In terms of power output, these generators come in a range of sizes, catering to different energy needs. From providing basic lighting and charging capabilities to supporting essential home appliances, portable generators offer a scalable solution for varying power requirements.

In summary, a portable generator is a compact, mobile power source that proves invaluable in situations where a reliable and convenient electricity supply is crucial. Whether you’re camping in the wilderness or dealing with unexpected power outages, these generators offer a flexible and efficient solution to keep things running smoothly.

How Does a Portable Generator Work?

Portable generators have become essential for providing power in various situations, from outdoor events to emergency situations. Understanding the mechanics of these generators is crucial for optimal use.

At the heart of a portable generator is an internal combustion engine, typically fueled by gasoline or propane. When you start the generator, the engine ignites the fuel, initiating a controlled explosion. This process transforms chemical energy into mechanical energy, which powers the generator’s main component: the alternator.

The alternator is a key player in the generator’s functionality. As the engine spins the alternator, it generates alternating current (AC) electricity. However, the electricity produced by the alternator is not yet suitable for most applications. Therefore, it goes through a critical process known as rectification.

During rectification, the AC electricity is converted into direct current (DC) electricity by the generator’s rectifier. This transformation is crucial because most household appliances and electronic devices require DC power to operate.

To make the power usable for a broader range of devices, the generator incorporates an inverter. The inverter takes the DC power and converts it back into AC power. What sets portable generators apart is their ability to produce clean power – a stable and consistent flow of electricity with minimal fluctuations in voltage and frequency. This is particularly important for sensitive electronics.

The control panel of a portable generator allows users to monitor and regulate the electrical output. It typically includes outlets for different types of devices, circuit breakers to protect against overloads, and often, a voltage regulator to maintain a steady voltage output.

In summary, the process of a portable generator involves the combustion engine driving the alternator, which produces AC power. This AC power is then rectified to DC and inverted back to clean AC power, ready to power your essential appliances and devices. Understanding this process empowers users to make the most of their portable generators in various situations.

What Size Wire Do I Need for a Portable Generator?

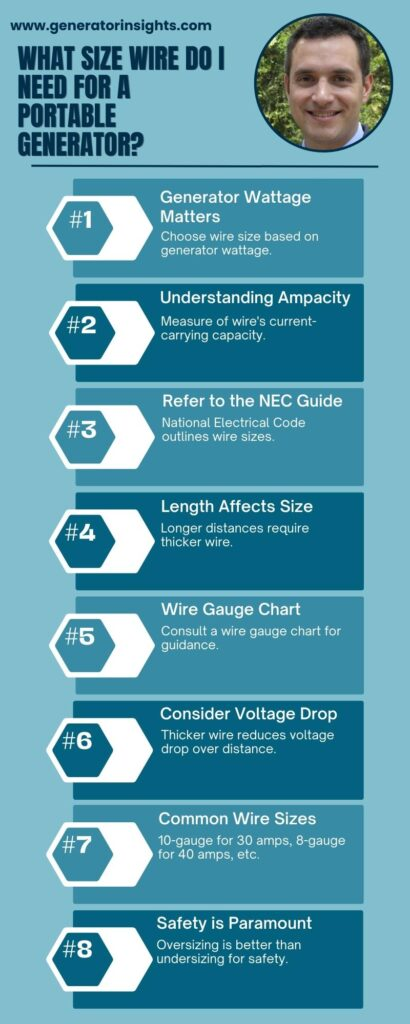

Selecting the appropriate wire size for your portable generator is crucial to ensure safety and optimal performance. The wire size is determined by the generator’s amperage and the distance between the generator and the connected devices. Choosing the correct wire gauge prevents power loss, overheating, and potential hazards.

For a 30-amp generator, a common choice for many portable generators, a 10-gauge wire is recommended for up to 30 feet. Beyond 30 feet, it’s advisable to move up to a 8-gauge wire to compensate for voltage drop. This is vital in maintaining a stable power supply during operation.

In the case of a 50-amp generator, often used for larger power needs, such as RVs or construction sites, a 6-gauge wire is typically suitable for distances up to 50 feet. Beyond this, upgrading to a 4-gauge wire becomes necessary to mitigate voltage drop and ensure efficient power transmission.

Always refer to the generator’s manual for specific requirements, and if in doubt, consult with a professional electrician to ensure compliance with local codes and regulations. Proper wire sizing guarantees a reliable and secure power connection for your portable generator, preventing potential risks associated with inadequate wiring.

What are Different Types of Wire Gauges for Portable Generator?

When considering a portable generator, understanding the wire gauges is crucial for safe and efficient operation. Wire gauge refers to the thickness or diameter of the wire, influencing its ability to carry electrical current without excessive heat buildup. Let’s delve into the various types of wire gauges commonly used for portable generators.

| Wire Gauge Type | Description |

|---|---|

| 10 AWG | This is a robust wire gauge suitable for longer distances, ensuring minimal power loss. Ideal for larger portable generators requiring extended cord lengths. |

| 12 AWG | A versatile option suitable for medium-sized generators, providing a balance between flexibility and current-carrying capacity. Commonly used for household portable generators. |

| 14 AWG | Lighter and more flexible, the 14 AWG wire gauge is suitable for shorter distances and lower-powered generators, making it a practical choice for smaller portable units. |

| 16 AWG | Reserved for light-duty applications, the 16 AWG wire gauge is suitable for short cord lengths and lower-powered generators, ensuring optimal performance in specific scenarios. |

| 8 AWG | A heavy-duty wire gauge suitable for high-powered generators and longer distances. This gauge minimizes power loss and is often used in professional or industrial settings. |

| 6 AWG | Reserved for generators with substantial power needs and extended cord lengths. The 6 AWG wire gauge offers excellent conductivity and is commonly employed for heavy-duty portable generators. |

| 18 AWG (SPT-2) | An ultra-flexible wire gauge suitable for specific applications where space and flexibility are critical. While not as common for generators, it may be used in specialized setups. |

| 2/0 AWG | A large and robust wire gauge designed for generators with extremely high power requirements. Typically used in industrial or heavy-duty generator setups. |

Understanding the appropriate wire gauge for your portable generator ensures safe power distribution and prevents overheating issues. Always consult the generator’s manual for recommended wire gauge specifications.

Factors to Consider When Choosing a Wire for Your Portable Generator

Understanding Your Electrical System

An understanding of the electrical system is necessary in order to determine what size wire is needed for a portable generator. Power monitoring and alternative power sources are essential components to consider when evaluating wiring needs.

The wattage rating of the generator must be taken into account, as too much or too little can be dangerous. A general rule for sizing wires is that they should be no smaller than the rated output of the generator, which will vary depending on the type and model being used.

Different types of wiring have different specifications and amperages that should be carefully reviewed before any installation work begins. It is also important to ensure that wiring meets national safety requirements and building codes for electricity use in residential areas.

Adequate grounding must also be factored into consideration, as this ensures electric current runs properly through all outlets connected to the generator’s circuit board.

Ultimately, selecting an appropriate-sized wire for a portable generator requires a thorough understanding of local regulations, as well as knowledge about power monitoring tools and alternative power sources available.

Calculating Amperage Requirements

Calculating the amperage requirements for an electrical circuit involves taking into account the voltage rating of the circuit, as well as any additional loads that may be placed on it.

It is also important to follow safety protocols when dealing with electricity to ensure proper working order and avoid potential damage or injury.

A thorough understanding of these principles is necessary in order to ensure that your electrical system operates safely and efficiently.

Voltage Rating

Considering the voltage rating of the portable generator is essential in determining the size of wire needed. Electromagnetic fields can be generated by different voltages, and it’s important to select a wire that can handle this current safely.

Wire size is determined by amperage requirements and voltage drop; higher voltages require heavier wires to reduce losses associated with high currents travelling through smaller gauges. An inadequate selection could lead to overheating, which would create an unsafe environment.

Additionally, selecting a wire that is too heavy or oversized for the voltage may result in increased cost and labor for installation. It’s important to consider not only working voltage levels but also emergency conditions such as surge protection needs when deciding what type of wire should be used.

Therefore, taking into account all factors before choosing a size is paramount in ensuring safe operation for any portable generator setup.

Circuit Loads

Accurately calculating the circuit loads is crucial for determining the appropriate size of wire to use in a portable generator setup. It is important to consider both the voltage rating and the electrical load when deciding on an appropriate wire gauge.

The higher the voltage, the thicker the wire should be; conversely, lower voltages require thinner wires. Additionally, heavier electrical loads require thicker wires than lighter loads.

Current carrying capacity should also be considered, as this will determine how much electricity can travel through a given wire before it overheats and becomes dangerous.

To ensure safety, one should seek professional advice regarding their specific situation and requirements before purchasing any wiring materials for a portable generator setup.

Selecting the Right Wire Gauge

The selection of the appropriate wire gauge for a portable generator is essential. The alternative power sources used to run such generators require electrical wiring that can handle its specific voltage and wattage output. It is important to select the right gauge of wire in order to ensure safety, efficiency, and reliability when using a portable generator. Wire insulation should also be taken into account when selecting the right wire gauge for a portable generator’s needs.

Wire gauges are measured by thickness and range from 0 (thickest) to 40 (thinnest). Thicker wires are able to handle higher current loads with less resistance. To determine the right size wire, one must consider the intended purpose of the portable generator as well as its capacity for producing electricity. Generally speaking, smaller generators that produce lower wattages will require thinner wires than larger generators that produce higher wattages.

It is also important to consider how long it will take for an electric current to travel through the wires connecting a portable generator with its end use appliance or device. To maximize safety and reduce energy loss due to heat buildup, it is recommended that shorter runs should use thicker wires while longer runs should use thinner wires with greater insulation protection against overheating and other hazards caused by high voltage surges and fluctuations in power supply quality.

Checking Local Electrical Codes

When discussing the topic of checking local electrical codes, it is important to note the regulations and guidelines that may be in place with regards to electricity use.

Local and state authorities will have specific requirements for safety when dealing with electrical systems, including portable generators.

It is beneficial to understand these regulations prior to starting a project involving electric wiring or installation of a generator.

Regulations

Regulations governing the use of portable generators vary by locale and may include wire size specifications. Power supply, installation costs, and safety are among the primary considerations for local electrical codes. Wire sizes must be adequate to handle the power needs of the generator being used. This is based on factors such as wattage output, length of wire needed for connection, and number of circuit breakers required.

Further information can be obtained from local building inspectors or utility companies regarding regulations and guidelines specific to a particular area. Connections should always be made with UL certified materials that meet established safety standards in order to prevent potential hazards.

The transition into subsequent sections about guidelines provides further guidance on how to select safe wiring options for a portable generator.

Guidelines

Guidelines for selecting safe wiring options for a portable generator depend on factors such as wattage output, length of connection, and number of circuit breakers. When considering alternative power sources, it is important to evaluate the best method to transfer power from the generator to the electrical panel. Factors like distance of connection, wire gauge size, type of conduit used, and safety switches should be taken into account.

- Ensure proper insulation when running wires;

- Use appropriate wire gauge size depending on wattage output;

- Consider distance when connecting with conduit;

- Utilize safety switches or ground fault circuit interrupters (GFCI) for added protection.

Types of Wiring

Wiring for a portable generator must be chosen based on the specific requirements of the application. Different types of wiring can have different capabilities and safety risks associated with them.

Battery connections, typically used for smaller loads or starting the engine, require very thin wire with low resistance and higher gauge ratings.

Generator placement is important, as it determines the type of wire needed to connect it to the load. For large loads, heavy-duty wire should be used to prevent overheating or electrical fire due to overloading.

If multiple pieces of equipment need power from a single generator, special consideration must be given to ensure that all connected items do not overload the system.

These factors should be taken into account when selecting the type and size of wiring for your portable generator installation.

Grounding Requirements

The importance of properly grounding a portable generator cannot be overstated, as it helps to protect against electric shock and reduce the risk of electrical fires. Grounding involves connecting the neutral wire of the generator to a ground rod. To do this safely, you must use an appropriate size and type of wire.

Furthermore, the length of the wire used needs to meet certain requirements:

- The wire should not be too long; if it is too long then more voltage drop will occur in the circuit.

- It should also not be too short, as this can result in overheating or breakage due to tension.

- The gauge of the wire also matters; thicker wires are able to carry more current without being damaged or becoming dangerous.

Installing the Wiring

Once the appropriate length and gauge of wire has been determined, the next step is to install it correctly. This process requires carefully following instructions related to grounding requirements and taking into account wireless connectivity as well as power consumption. It is important to ensure that all wiring connections are secure in order to prevent any potential damages from occurring when using the portable generator.

When installing wiring for a portable generator, it is essential to use approved materials that have been designed specifically for this purpose. These materials include insulated copper wires with a stranded or solid core structure, as well as nonmetallic sheathed cables with an inner layer of corrosion-resistant insulation which meets safety standards. Additionally, all electrical connections should be properly secured with connectors such as ring terminals or spade lugs.

The installer should also take into consideration environmental factors such as temperature, ultraviolet radiation, moisture levels, and hazardous chemicals when selecting suitable electrical wire insulation material for their application. Furthermore, measures should be taken in order to reduce electromagnetic interference (EMI) by limiting current flow along long runs of wire and providing adequate shielding around sensitive components.

Troubleshooting Common Generator Wiring Issues

| Issue | Symptoms | Possible Causes | Solution |

|---|---|---|---|

| No Power Output | No electricity from the generator. | 1. Faulty wiring connections. 2. Damaged power outlet. | 1. Inspect and secure all wiring connections. 2. Replace the damaged power outlet. |

| Intermittent Power | Power output fluctuates. | 1. Loose connections. 2. Faulty voltage regulator. | 1. Tighten all electrical connections. 2. Replace the faulty voltage regulator. |

| Generator Not Starting | The generator fails to start. | 1. Dead battery. 2. Faulty ignition switch. | 1. Replace the battery. 2. Install a new ignition switch. |

| Overheating | Generator becomes excessively hot. | 1. Inadequate ventilation. 2. Overloaded circuit. | 1. Ensure proper ventilation around the generator. 2. Reduce the load on the circuit. |

| Low Voltage Output | Insufficient voltage from the generator. | 1. Faulty alternator. 2. Worn-out brushes. | 1. Replace the faulty alternator. 2. Install new brushes if needed. |

| Fuel Supply Issues | Generator runs out of fuel or fuel not reaching the engine. | 1. Empty fuel tank. 2. Clogged fuel filter. | 1. Refill the fuel tank. 2. Replace the clogged fuel filter. |

| Excessive Vibration | Unusual shaking or vibrating during operation. | 1. Loose mounting bolts. 2. Misaligned engine components. | 1. Tighten all mounting bolts. 2. Realign engine components as necessary. |

Generator Wiring Safety Tips

Ensuring safe wiring for your generator is crucial to prevent potential hazards and ensure reliable power supply. Here are some Generator Wiring Safety Tips to keep in mind:

- Choose the Right Wiring Gauge: Ensure the wiring gauge is appropriate for the generator’s power output. Using an inadequate gauge can lead to overheating and electrical fires.

- Proper Grounding: Always ground your generator to prevent electrical shock. Connect the grounding wire to a designated grounding rod, following manufacturer guidelines.

- Use Outdoor-Rated Extension Cords: When extending the reach of your generator, employ outdoor-rated extension cords to avoid overheating and potential fire risks.

- Regular Inspections: Periodically inspect the wiring for wear, fraying, or damage. Promptly replace any compromised wiring to maintain safety standards.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for wiring specifications and installation. This ensures optimal performance and safety.

- Install a Transfer Switch: Implement a transfer switch to seamlessly switch between utility power and generator power, preventing backfeed and protecting utility workers.

- Keep it Dry: Protect wiring and connections from the elements. Ensure all components are sheltered and avoid exposure to moisture to prevent short circuits.

- Emergency Shutdown Procedures: Familiarize yourself with the emergency shutdown procedures. In case of any issues, knowing how to quickly cut power can prevent accidents.

- Professional Installation: If uncertain about wiring or installation, seek professional assistance to guarantee compliance with safety standards.

- Proper Ventilation: Ensure proper ventilation around the generator and its wiring. Adequate airflow prevents overheating during extended operation.

- Labeling Connections: Clearly label all wiring connections for easy identification. This simplifies troubleshooting and maintenance, minimizing the risk of errors.

- Secure Connections: Tighten all electrical connections to prevent loose wires, which can lead to arcing and potential fire hazards.

- Regular Testing: Conduct regular testing of the generator and its wiring to identify any issues before they escalate. This proactive approach enhances overall safety.

- Fuse Protection: Install proper fuses in the circuit to protect against overloads. Fuses act as a fail-safe, interrupting the circuit in case of excessive current.

- Keep Children and Pets Away: Establish a safety perimeter around the generator to keep children and pets away, minimizing the risk of accidents or injuries.

- Monitor Fuel Lines: Regularly inspect fuel lines for any signs of leaks. Leaking fuel poses a significant fire hazard, so addressing this promptly is crucial.

- Emergency Lighting: Install emergency lighting near the generator and its wiring. This aids visibility during power outages and facilitates safer operation.

- Avoid Overloading: Avoid overloading the generator beyond its rated capacity. Overloading can lead to equipment damage and compromise safety.

- Educate Users: If multiple individuals operate the generator, ensure they are educated on safety protocols. Clear communication can prevent misuse and accidents.

- Battery Maintenance: If your generator includes a battery for starting, conduct regular battery maintenance to ensure reliable starts and prevent corrosion.

Remember, prioritizing safety in generator wiring is essential for a reliable and hazard-free power supply.

Conclusion

In conclusion, selecting the appropriate wire size for a portable generator is pivotal for a safe and efficient power backup system. By considering factors like distance, voltage, and amperage, you can ensure reliable power transmission without risking overloads or voltage drops.

This guide on What Size Wire Do I Need for a Portable Generator equips you with the knowledge to make an informed decision, whether you’re setting up for emergencies or remote power needs. With the right wire gauge in place, you can have confidence in the performance and reliability of your portable generator.

References

- Linear electric actuators and generators

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

Frequently Asked Questions

How Do I Ensure My Generator Is Safe to Use?

To ensure safety when using a generator, it is important to adhere to electrical safety protocols and take necessary precautions. This includes checking for loose connections, verifying the correct wiring and size of wire used, grounding the unit correctly, and following all manufacturer guidelines. Doing so will help create a safe environment in which to operate the generator.

What Is the Best Way to Install the Wiring for My Generator?

Installing wiring for a portable generator requires careful consideration of sizing requirements and power sources. For example, consider a hypothetical situation where an electrician must wire a generator in a residential home.

The electrician must ensure the correct gauge of wire is used to prevent damage from overloading and inspect all connections for proper grounding. With the right knowledge and care, wiring can be safely and efficiently installed to provide reliable power.

How Do I Know if the Generator Is Compatible With My Home’s Electrical System?

Determining generator compatibility with a home’s electrical system requires an understanding of alternative power sources, and the ability to make accurate power capacity calculations.

Knowing the total load and individual appliance requirements is key in determining proper compatibility. Professional assistance may be necessary to ensure safe installation for long-term use.

How Can I Determine the Amount of Power My Generator Will Need to Provide?

In order to determine the power required for a portable generator, one must calculate the amperage while preventing overload. This involves understanding the current draw of each appliance and calculating the total amount of power needed to run them efficiently. Doing this accurately will help ensure that the generator is suitable for your needs.

Is There a Specific Type of Wiring That Should Be Used for a Portable Generator?

When connecting a portable generator to your home, it is important to use appropriate wiring that meets local electrical codes and complies with regulations. Wiring must be of the correct type and size to prevent overloads and maintain safety. Choosing the right wire is essential for safe connection and reliable operation.

What size cable do I need to connect a generator to my house?

To connect a generator to the house, one should choose a power cord that matches the generator’s most powerful outlet. For instance, if the generator has a 50-amp outlet, a 50-amp power cord is required. Opting for a lower-amp cord may lead to underutilized power potential and potential damage to equipment.

What size wire do I need for a 7500 watt generator?

For a 7500-watt generator, MPI Tools’ 10-foot Locking Generator Cord is recommended. This cord combines efficient power transfer (125/250v – 7500 watts) with durable craftsmanship, featuring a 10-gauge wire to ensure a stable power supply for various needs.

What size wire is needed for a 30 amp generator?

For a 30 amp generator, assuming it’s a 120-volt or 240-volt (single phase) setup and a reasonable length (not exceeding 30 feet), a 10 AWG wire should suffice. A 30 amp generator requires a minimum of #10 copper conductor. If the wiring distance is over 50 feet, it’s advisable to use a #8 wire for a capacity of 50 amps.