Tired of navigating through a maze of confusing instructions on how to ground a portable generator? We get it – the struggle is real. Picture this: you’re out in the great outdoors, ready to power up your portable generator for a camping trip or a tailgate party, and suddenly, the jargon-laden manuals leave you scratching your head. But fear not! In this guide, we’re diving into the nitty-gritty of grounding your portable generator with simplicity in mind.

No more deciphering complex diagrams. Get ready for a straightforward journey as we demystify the art of grounding, making it as easy as enjoying your favorite outdoor activities.

Jump to a Specific Section

- 1 Main Highlights

- 2 What Is Grounding?

- 3 Do all Generators Need to be Grounded?

- 4 What Happens if You Do Not Ground a Portable Generator?

- 5 How To Ground A Portable Generator?

- 6 What are the Benefits of Grounding a Portable Generator?

- 7 What are the Requirements of Grounding a Generator?

- 8 Does My Generator Need a Grounding Rod?

- 9 Troubleshooting Common Generator Grounding Issues

- 10 Generator Maintenance Tips

- 11 Generator Safety Tips

- 12 Conclusion

- 13 References

- 14 Frequently Asked Questions

- 14.1 Can I use a regular extension cord to connect my portable generator to a grounding rod?

- 14.2 Is it necessary to ground a portable generator if it is only used occasionally?

- 14.3 How deep should the grounding rod be inserted into the ground?

- 14.4 Can I use a metal pipe instead of a grounding rod for grounding my portable generator?

- 14.5 What are the potential risks of not grounding a portable generator properly?

- 14.6 Do portable generators need to be grounded?

- 14.7 What are the grounding methods of a generator?

- 14.8 What happens if you don’t ground a portable generator?

Main Highlights

- Proper grounding is essential for achieving a tight and reliable connection and avoiding common mistakes.

- Testing methods, such as using a ground resistance tester and visual inspection, help ensure proper grounding.

- Regular inspection and maintenance of components, such as ground rods, clamps, cables, and connections, is important.

- Maintaining grounding equipment, including conducting regular testing and cleaning or replacing damaged components, is crucial for safe and effective operation.

What Is Grounding?

Grounding establishes a connection between electrical equipment and the Earth, creating a path for excess current to flow safely into the ground. This practice prevents electrical shocks, protects devices from voltage spikes, and promotes a stable operating environment. Essentially, grounding serves as a safeguard, channeling unwanted electrical energy away from sensitive equipment.

In practical terms, a common example of grounding is the three-pronged power plug found in many household appliances, where the third prong acts as the ground connection. This simple yet crucial principle is integral to the reliability and safety of electrical systems.

Do all Generators Need to be Grounded?

Generator grounding is essential to prevent electrical shocks, protect equipment, and maintain a stable electrical system. Grounding provides a pathway for fault currents to flow safely into the ground, reducing the risk of electrical fires and injuries. National Electrical Code (NEC) guidelines often dictate grounding requirements based on the generator’s size and usage. Portable generators, for example, may have different grounding needs compared to larger, permanent installations.

- Portable Generators: Portable generators, commonly used for temporary power needs, may not always require grounding. However, some models come with grounding features, such as grounding terminals, allowing users to connect the generator to a grounding rod. It’s essential to follow the manufacturer’s guidelines regarding grounding for portable generators to ensure safe operation. It is worth mentioning that when a portable generator is supplying electrical power to a building through a transfer switch, like in homes, offices, shops, trailers, or similar structures, it is crucial to establish a connection to a grounding electrode system. This often involves linking the generator to a driven ground rod.

- Permanent Generators: Larger, permanent generators, such as those used in standby power systems for buildings, often require grounding. These generators are typically connected to the building’s grounding system to ensure proper dissipation of fault currents. Compliance with local electrical codes and standards is crucial when installing and grounding permanent generators.

What Happens if You Do Not Ground a Portable Generator?

Without proper grounding, a portable generator becomes susceptible to electrical faults and poses a significant risk to both users and connected devices. In the absence of a grounded connection, the generator may produce what is known as “stray voltage” or “floating ground.” This occurs when the generator is not adequately connected to the Earth, leading to an uneven distribution of electrical potential. Consequently, anyone in contact with the generator or connected appliances may experience electric shocks.

Moreover, the lack of proper grounding can compromise the stability of the generator’s power output. Electronic devices and appliances require a consistent and stable power supply to function optimally. Without a grounded connection, the generator may produce erratic voltage levels, potentially damaging sensitive equipment such as computers, refrigerators, or medical devices.

In addition to the safety risks and potential damage to electronics, the absence of grounding might also result in the generator failing to meet regulatory compliance. Local electrical codes and safety standards often mandate the proper grounding of generators to ensure safe operation. Neglecting this requirement could lead to legal consequences and penalties.

In summary, neglecting to ground a portable generator can lead to a range of issues, from safety hazards and electrical shocks to damage of connected devices and legal repercussions. It is imperative for users to understand the significance of grounding and incorporate this essential step into their generator setup for a safer and more reliable power source.

How To Ground A Portable Generator?

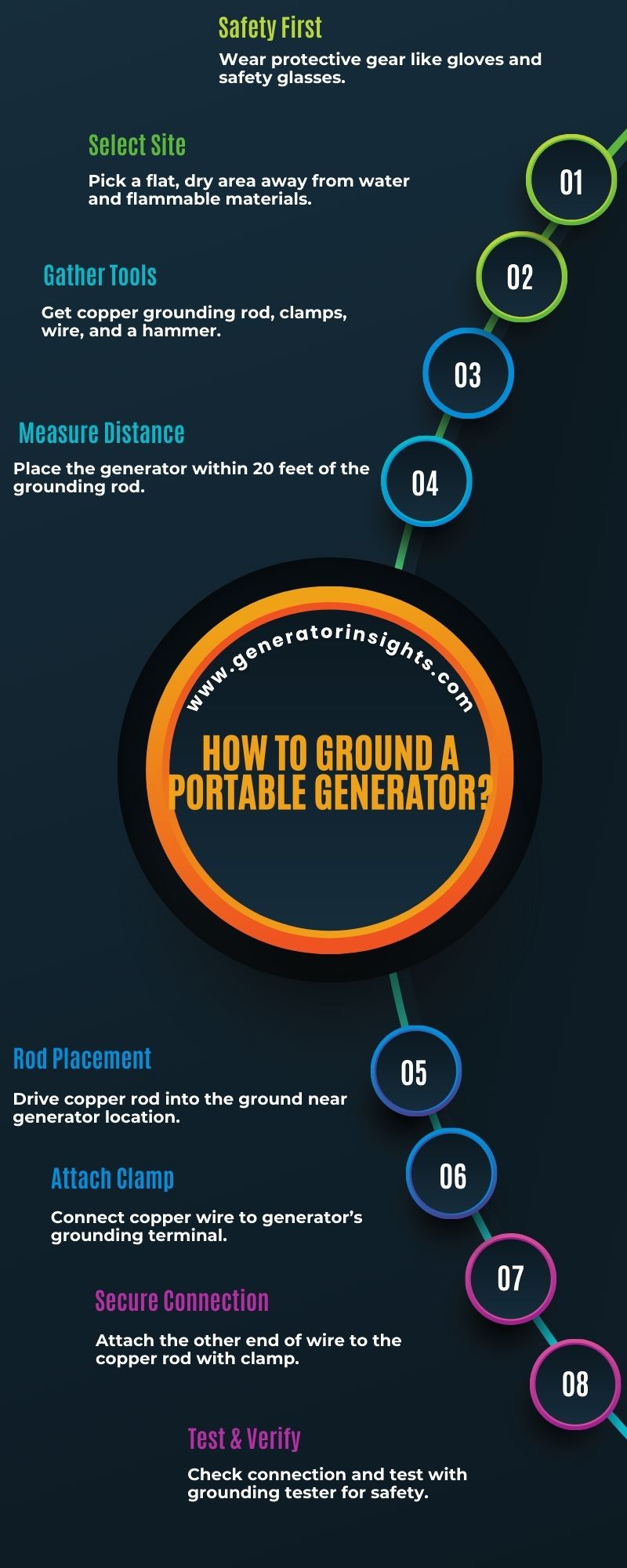

When setting up a portable generator, it’s crucial to ensure proper grounding to enhance safety and protect your equipment. Follow these steps to correctly ground your generator.

- Understand Local Codes:

- Research and familiarize yourself with local electrical codes related to generator grounding.

- Compliance ensures your setup meets safety standards.

- Select a Suitable Location:

- Place the generator on a dry, level surface away from standing water or wet conditions.

- Ensure the area is well-ventilated to prevent exhaust buildup.

- Use a Grounding Rod:

- Drive a copper grounding rod into the ground near the generator.

- Connect the generator’s grounding terminal to the rod using a copper grounding wire.

- Check the Generator’s Manual:

- Refer to the generator’s manual for specific grounding instructions provided by the manufacturer.

- Follow any unique guidelines or requirements outlined.

- Avoid Overloading:

- Prevent overloading the generator by using a heavy-duty extension cord for devices.

- Ensure the total wattage doesn’t exceed the generator’s capacity.

- Regularly Inspect Connections:

- Periodically check the grounding wire connections for any signs of wear or damage.

- Tighten connections if necessary to maintain a secure ground.

Proper grounding minimizes the risk of electrical shock and helps prevent equipment damage.

Now let’s discuss the step-by-step systematic way of grounding a portable generator.

Gather the Necessary Tools

To successfully prepare for the grounding process, a range of essential tools and equipment should be gathered. When it comes to grounding a portable generator, there are several tools needed and equipment required to ensure a safe and effective setup.

One of the most important tools is a grounding rod or stake, which is typically made of copper or galvanized steel. This rod is used to create a direct path for electrical currents to flow into the ground.

Additionally, you will need copper wire that is specifically designed for grounding purposes. The size of the wire will depend on the power rating of your generator and the distance between the generator and the grounding location. Other necessary tools include wire cutters, pliers, and a hammer to secure the grounding rod into the earth.

In terms of equipment required, you may also need a portable generator ground fault circuit interrupter (GFCI). This device provides additional protection by detecting any imbalances in electrical current flow and shutting off power if necessary. It is crucial to check your generator’s user manual or consult with an electrician to determine if this equipment is necessary for your specific model.

Having gathered all these essential tools and equipment, you can proceed to identify a suitable grounding location without compromising safety standards.

Identify a Suitable Grounding Location

Identifying an appropriate location for grounding involves careful consideration of various factors such as soil composition, proximity to water sources, and distance from any flammable materials. Choosing the right grounding method is crucial to ensure the safe operation of a portable generator.

To determine a suitable grounding location, follow these guidelines:

- Conduct a thorough assessment of the soil composition in the area where the generator will be placed. It is essential to have good electrical conductivity for effective grounding.

- Avoid areas that are prone to flooding or have high water tables. Water can interfere with proper grounding and increase the risk of electrical shock.

- Keep a safe distance from any flammable materials, including vegetation, fuel tanks, and other combustible substances. This precaution minimizes the risk of fire in case of electrical faults.

- Maintain a reasonable distance from utility lines or underground cables to prevent interference with their operation and avoid potential accidents.

Ensuring safety measures during this stage is vital to promote secure functioning of the generator system. Once an appropriate location has been identified, prepare yourself for preparing the grounding rod and cable without delay or hesitation.

Prepare the Grounding Rod and Cable

Preparing the grounding rod and cable is an essential step in ensuring the safe and effective operation of a portable generator. This involves two main tasks: installing the grounding rod and connecting the grounding cable.

First, let’s focus on the grounding rod installation. The grounding rod serves as a vital connection between the generator and the earth, providing a low-resistance path for electrical currents. It should be made of copper or galvanized steel, with a minimum diameter of half an inch and a length of at least eight feet.

The rod should be driven vertically into the ground near the generator, ensuring that it is securely placed within soil that has good electrical conductivity.

Moving on to the grounding cable connection, it is crucial for effective grounding. A copper wire with a gauge size specified by local codes should be used to connect the grounding terminal on the generator to the grounding rod. Before connecting, strip both ends of the wire.

One end should be securely connected to the grounding terminal using appropriate connectors. The other end should be tightly connected to the grounding rod using approved clamps or connections.

To summarize, preparing the grounding rod and cable involves installing the grounding rod securely into the ground near the generator and connecting the grounding cable between the generator’s grounding terminal and the grounding rod. These steps are crucial for providing a safe and effective grounding system for the portable generator.

Install the Grounding Rod

The installation process for the grounding rod involves securely driving it into the ground near the designated location. To ensure a proper installation, there are several grounding rod installation tips that should be followed.

First, it is important to choose a suitable location for the grounding rod where it will be easily accessible and close to the generator. The ground should be moist or damp to enhance conductivity. Before driving the rod into the ground, remove any rocks or obstructions in its path to prevent bending or damage during installation.

To install the grounding rod, use a mallet or hammer to drive it vertically into the ground until only a few inches are visible above the surface. It is essential that the rod is driven deep enough so that it remains firmly in place and provides adequate grounding. A depth of at least 8 feet is recommended for optimal performance.

Common mistakes in grounding rod installation include not driving it deep enough into the ground, using a bent or damaged rod, or installing it in an unsuitable location with poor soil conductivity.

Once the grounding rod has been securely installed, you can proceed to connect the grounding cable to your generator.

Connect the Grounding Cable to the Generator

To establish a secure electrical connection, the grounding cable should be carefully connected to the generator, ensuring proper safety measures are followed. Here are some important considerations when connecting the grounding cable to a portable generator:

- Proper cable length: The grounding cable should be long enough to reach from the grounding rod to the generator. It is essential to avoid using extension cords or makeshift connections, as they may compromise the effectiveness of the grounding system.

- Secure connection: The grounding cable must be securely attached to both the generator and the grounding rod. This can be achieved by using appropriate clamps or connectors that provide a tight and reliable connection.

- Avoid common mistakes: When connecting the grounding cable, it is crucial to avoid common mistakes such as using damaged cables or failing to ensure proper insulation. These mistakes can lead to electrical hazards and compromise safety.

Additionally, it is worth mentioning that there are alternative methods for grounding portable generators, such as using ground-fault circuit interrupters (GFCIs) or bonding neutral-to-ground at the generator.

However, these methods may not be suitable for all situations and should only be used if recommended by a qualified electrician. If interested you can read how to connect a generator with transfer switch here. Moreover, you can read how to connect a generator without transfer switch here.

Once the grounding cable is securely connected, it is essential to test the grounding connection before operating the generator.

Test the Grounding Connection

After securely connecting the grounding cable, it is crucial to verify the effectiveness of the grounding connection through a thorough testing process. Testing methods and troubleshooting tips can help ensure that the generator is properly grounded and functioning as intended.

One commonly used testing method involves using a ground resistance tester. This device measures the resistance between the generator’s grounding system and an auxiliary ground rod. By comparing this resistance reading to acceptable limits specified by local electrical codes or manufacturers’ recommendations, one can determine if the grounding connection is adequate.

In addition to using a ground resistance tester, visual inspection can also be helpful in identifying any potential issues with the grounding connection. Look for loose or corroded connections, damaged cables, or signs of wear and tear that could affect the effectiveness of the system.

If any problems are detected during testing or inspection, troubleshooting tips can aid in resolving them. These may include tightening loose connections, cleaning corrosion from terminals, replacing damaged cables, or consulting a professional electrician for further assistance.

To ensure ongoing safety and reliability, regularly inspecting and maintaining the grounding system is essential. This will help identify any potential issues early on and prevent future problems that could compromise the performance of the generator’s grounding connection.

Regularly Inspect the Grounding System

Regularly inspecting and maintaining the grounding system is akin to tending a garden, ensuring that potential issues are promptly addressed and preventing future problems from taking root. The grounding system of a portable generator is crucial for safety, as it provides a path for electrical current to flow into the ground in case of a fault or surge.

Inspecting the grounding system involves visually examining all components such as ground rods, clamps, conductor cables, and connections to ensure they are intact and free from damage or corrosion. Additionally, it is important to check that there is proper continuity between the generator frame and the grounding electrode system.

Maintaining the grounding equipment entails conducting regular testing to verify its effectiveness. This can be done using a ground resistance tester which measures how well the system dissipates electrical energy into the ground. The results should comply with industry standards and if any deviations are found, appropriate actions should be taken to rectify them.

These actions may include cleaning corroded connections, replacing damaged cables or rods, or repositioning them for better contact with the earth.

| Component | Inspection Procedure |

|---|---|

| Ground Rods | Visually inspect for signs of damage or corrosion |

| Clamps | Ensure clamps are securely fastened |

| Conductor Cables | Check for fraying or wear |

| Connections | Examine connections for tightness and signs of corrosion |

| Continuity | Verify proper connection between generator frame and ground |

By regularly inspecting and maintaining the grounding system, owners can ensure their portable generators operate safely and effectively while mitigating potential hazards associated with electrical faults.

What are the Benefits of Grounding a Portable Generator?

Grounding a portable generator is a crucial step in ensuring both safety and optimal performance. Proper grounding helps to create a pathway for the electric current to safely dissipate, reducing the risk of electrical shock and fire hazards. Let’s delve into the specific benefits of grounding a portable generator.

- Enhanced Safety:

- Grounding minimizes the risk of electrical shock by providing a controlled path for current flow, safeguarding both users and connected devices.

- Protection Against Electrical Faults:

- In the event of a short circuit or electrical fault, grounding helps to quickly divert excess electrical energy to the ground, preventing damage to the generator and connected equipment.

- Compliance with Safety Standards:

- Proper grounding ensures compliance with safety standards and regulations, which is essential for both residential and commercial use of portable generators.

- Stabilized Voltage Output:

- Grounding contributes to a stable electrical environment, preventing voltage fluctuations that could potentially damage sensitive electronic devices connected to the generator.

- Fire Prevention:

- By grounding the generator, the risk of electrical fires is significantly reduced, as any potential electrical fault is promptly addressed through the grounding system.

- Equipment Longevity:

- Grounding helps extend the lifespan of the generator and connected appliances by preventing damage caused by electrical surges or faulty currents.

What are the Requirements of Grounding a Generator?

Proper grounding of a generator is essential for both safety and operational efficiency. Grounding helps dissipate excess electrical energy, preventing electrical shocks and equipment damage. Here are the key requirements for grounding a generator:

| Requirement | Description |

|---|---|

| 1. Grounding Electrode System | Ensure the generator is connected to a grounding electrode system. This system typically includes metal rods driven into the ground, creating a safe path for electrical currents to dissipate. |

| 2. Neutral-Ground Bonding | Establish a solid neutral-ground bonding. This connection helps maintain the generator’s electrical balance and ensures that fault currents are directed away from sensitive equipment. |

| 3. Compliance with Local Codes | Adhere to local electrical codes and regulations when grounding the generator. Compliance ensures that the installation meets safety standards and legal requirements. |

| 4. Proper Sizing of Conductors | Use conductors with a sufficient gauge to handle the generator’s electrical load. Undersized conductors can lead to overheating and pose a significant risk of fire or equipment damage. |

| 5. Regular Inspection and Maintenance | Implement a schedule for routine inspection and maintenance. This ensures that the grounding system remains effective over time, identifying and addressing issues before they become problematic. |

Remember, proper grounding not only safeguards personnel and equipment but also contributes to the reliable and efficient operation of the generator.

Does My Generator Need a Grounding Rod?

When setting up a generator, one crucial consideration is whether it requires a grounding rod. This question becomes pivotal for ensuring safety and proper functioning. Let’s delve into the various scenarios to determine whether your generator needs a grounding rod.

Scenario 1: Outdoor Generator Placement without a Permanent Structure

If your generator operates in an outdoor setting without a permanent structure, such as a standalone shed, it is advisable to install a grounding rod. This additional measure helps to dissipate excess electrical energy safely into the ground, minimizing the risk of electrical hazards.

Scenario 2: Proximity to Water Sources

Generators located in areas with a proximity to water sources should always be equipped with a grounding rod. This is crucial for preventing potential electrical shocks, especially in wet conditions. Ensuring a direct path for electrical discharge to the ground is essential for safety.

Scenario 3: Mobile Generators and Temporary Setups

For mobile generators or those used in temporary setups, the need for a grounding rod depends on the specific situation. If the generator is consistently connected to a properly grounded electrical system, additional grounding may not be required. However, in scenarios where the grounding is uncertain, it’s prudent to use a grounding rod for enhanced safety.

Thus, whether your generator needs a grounding rod depends on factors such as its location, the presence of existing grounding infrastructure, and the potential for exposure to moisture. Assessing these factors diligently ensures that your generator operates safely and efficiently. Always consult the generator’s manual and, if in doubt, seek professional advice for your specific setup.

Troubleshooting Common Generator Grounding Issues

| Issue | Introduction | Troubleshooting Steps |

|---|---|---|

| Improper Grounding | When generators aren’t properly grounded, it can lead to safety hazards and operational problems. | 1. Ensure the earth connection is securely established. |

| 2. Check for corrosion or damage to grounding wires. | ||

| 3. Use a multimeter to measure the ground resistance; it should be within the specified limits (e.g., below 1 ohm). | ||

| Ground Faults | Ground faults can disrupt the generator’s performance and pose a risk of electrical shock. | 1. Inspect the wiring for any signs of damage. |

| 2. Test for ground faults using an insulation resistance tester. Repair or replace faulty components. | ||

| Inadequate Grounding System | If the grounding system is inadequate, it may fail to dissipate excess electrical charge effectively. | 1. Ensure the grounding electrodes are correctly installed and meet local code requirements. |

| 2. Verify that the grounding conductor size is appropriate for the generator’s capacity. | ||

| 3. Regularly inspect and maintain the grounding system to prevent corrosion or degradation. | ||

| Floating Neutral | A floating neutral can lead to voltage instability and damage to connected equipment. | 1. Confirm that the generator’s neutral is properly connected to the grounding system. |

| 2. Use a voltmeter to check for any voltage imbalances between the neutral and ground; they should be equal. | ||

| 3. Address any loose or disconnected neutral connections promptly. | ||

| Overloaded Grounding System | Excessive electrical loads may overload the grounding system, compromising its effectiveness. | 1. Evaluate the generator’s capacity and ensure it matches the connected load. |

| 2. Upgrade the grounding system if the generator capacity exceeds the current grounding capability. | ||

| 3. Distribute heavy electrical loads across multiple grounding points to prevent overloading. |

Generator Maintenance Tips

Power outages can strike unexpectedly, making a well-maintained generator crucial for ensuring a continuous power supply. Regular maintenance not only enhances longevity but also guarantees optimal performance. Here are some key tips to keep your generator in top shape:

- Scheduled Inspections: Conduct routine checks on your generator to identify any signs of wear, loose connections, or potential issues before they escalate.

- Fluid Levels: Regularly check and replenish the oil and fuel levels to guarantee efficient operation. Proper lubrication is essential for preventing friction-related damage.

- Battery Health: Ensure the generator’s battery is charged and in good condition. A healthy battery is vital for a swift start when power is needed.

- Air Filter Checks: Keep the generator’s air filter clean and replace it as recommended by the manufacturer. A clogged filter can compromise performance and fuel efficiency.

- Coolant System Inspection: Verify the coolant levels and inspect the system for leaks. Overheating can lead to severe damage, so maintaining the right coolant levels is crucial.

- Capacitor Maintenance: Check and test the generator’s capacitors regularly. Faulty capacitors can lead to electrical issues, affecting the generator’s ability to produce a consistent power output.

- Run the Generator Regularly: Regularly starting the generator, even if it’s not in use, helps keep the engine components lubricated and prevents fuel system issues.

- Storage Considerations: If the generator is stored for an extended period, use a fuel stabilizer to prevent fuel deterioration. Empty the fuel tank or run the generator dry before storage to avoid gumming.

By adhering to these maintenance tips, you’ll ensure that your generator is ready to provide reliable power when you need it the most.

Generator Safety Tips

Generators are indispensable for providing power during outages, but ensuring their safe operation is paramount. Here are essential Generator Safety Tips to keep in mind:

- Proper Ventilation: Always operate generators in well-ventilated areas to prevent the buildup of harmful gases like carbon monoxide.

- Read the Manual: Familiarize yourself with the manufacturer’s guidelines for your specific generator model to understand its unique safety requirements.

- Regular Maintenance: Conduct routine checks on the generator, including fuel lines, filters, and oil levels, to guarantee optimal performance and identify potential issues early.

- Keep Flammable Materials Away: Position the generator away from flammable materials to reduce the risk of fire hazards.

- Carbon Monoxide Alarms: Install and regularly test carbon monoxide detectors near the generator area to provide an early warning of any dangerous gas levels.

- Grounding: Ensure proper grounding of the generator to prevent electrical shocks and protect both the equipment and users.

- Fuel Safety: Store fuel in approved containers, away from heat sources, and follow guidelines for proper storage to avoid spills and contamination.

- Emergency Shutdown: Understand and practice the emergency shutdown procedures to swiftly respond to potential dangers.

- Children and Pets: Keep children and pets away from the generator during operation to prevent accidents and injuries.

- Avoid Overloading: Respect the generator’s rated capacity and avoid overloading it to maintain efficient and safe operation.

- Cooling Time: Allow the generator to cool down before refueling to prevent accidental fires or burns. Follow the recommended cooldown period specified in the manual.

- Secure Placement: Place the generator on a stable, flat surface to prevent tipping and ensure safe operation. Avoid placing it on uneven or sloped terrain.

- Regular Testing: Periodically run the generator to ensure it starts easily and operates smoothly. This practice helps identify potential issues before they become major problems during an emergency.

- Extension Cord Safety: If using extension cords, ensure they are of sufficient gauge for the load and in good condition. Overloading cords can lead to overheating and pose a fire risk.

- Weather Considerations: Shelter the generator from the elements to protect it from rain and snow. Use appropriate covers or enclosures designed for your specific generator model.

- Professional Inspection: Schedule regular professional inspections to check for hidden issues and ensure all components are in good working order. This is especially important for standby generators.

- Emergency Services Awareness: Familiarize yourself with the location of emergency shut-off switches and how to quickly contact relevant services in case of a malfunction or emergency.

- Storage Precautions: If the generator is not in use for an extended period, follow proper storage procedures. This includes draining the fuel, disconnecting the battery, and storing it in a dry, cool place.

- Educate Users: Ensure that anyone who may need to operate the generator is familiar with its safety features and operation. Provide clear instructions to prevent accidents caused by misuse.

- Legal Compliance: Be aware of and adhere to local regulations regarding generator usage, emissions, and noise levels. Non-compliance may result in fines or other penalties.

Remember, adhering to these Generator Safety Tips is crucial to ensure the reliable and secure use of your generator.

Conclusion

In conclusion, understanding how to ground a portable generator is paramount for safe and effective operation. By following the proper grounding procedures, you not only protect your equipment but also ensure the safety of yourself and those around you.

Grounding mitigates the risk of electrical hazards and provides a reliable path for excess electrical currents. As you embark on utilizing your portable generator, let this guide be your trusted companion, offering you the knowledge and confidence to carry out grounding procedures accurately. With safety as your priority, you can fully enjoy the benefits of your generator while maintaining a secure environment for all.

References

- Development of 500 W PEM fuel cell stack for portable power generators

- Modeling low-bandgap thermophotovoltaic diodes for high-efficiency portable power generators

- Biomechanical energy‐driven hybridized generator as a universal portable power source for smart/wearable electronics

- Portable fuel cell power generator

Frequently Asked Questions

Can I use a regular extension cord to connect my portable generator to a grounding rod?

Using a regular extension cord to connect a portable generator to a grounding rod is not an effective method of grounding. Alternatives to a grounding rod for portable generator grounding include using ground stakes or connecting to a metal water pipe.

Is it necessary to ground a portable generator if it is only used occasionally?

Grounding a portable generator is necessary even if it is used occasionally. Pros of grounding include safety from electrical shock and prevention of damage to sensitive equipment. Grounding alternatives, such as using a ground fault circuit interrupter (GFCI), can also be effective.

How deep should the grounding rod be inserted into the ground?

The proper depth for inserting a grounding rod into the ground depends on the soil conditions and local codes. Generally, it is recommended to insert the grounding rod at least 8 feet deep using an installation technique that ensures good contact between the rod and the surrounding soil.

Can I use a metal pipe instead of a grounding rod for grounding my portable generator?

Using a metal pipe as an alternative grounding method for a portable generator is not recommended. It lacks the necessary conductivity and corrosion resistance of a grounding rod, compromising the effectiveness and safety of the grounding system.

What are the potential risks of not grounding a portable generator properly?

Potential hazards of not grounding a portable generator properly include electrical shock, fire, and damage to sensitive electronics. Proper grounding ensures electrical safety by providing a path for excess electricity to safely dissipate into the ground.

Do portable generators need to be grounded?

When a portable generator is supplying electrical power to a structure through a transfer switch, such as a home, office, shop, trailer, or similar space, it must be connected to a grounding electrode system. This commonly involves linking it to a driven ground rod for safety.

What are the grounding methods of a generator?

Two grounding methods for generators exist. The first is Solid Grounding, where the generator’s neutral point is directly connected to the earth. The second is Low Resistance Grounding, involving the use of a low-resistance grounding resistor between the generator’s neutral point and the earth.

What happens if you don’t ground a portable generator?

Failure to ground a generator poses hazards, including electrical overload that can damage the wiring or sensitive components of the electrical system, unless the generator has built-in overload protection. Additionally, there is a risk of electrocution from contact with ungrounded metal. Grounding is crucial for safe generator operation.