In the midst of relying on your trusty portable generator, have you ever found yourself puzzled by the unexpected symphony of pops and bangs emanating from its engine? It’s a common concern that often leaves people wondering, Why does my portable generator backfire?

Picture this: you’re enjoying the serenity of the great outdoors or weathering a power outage at home, and suddenly, your generator seems to voice its discontent. Fear not, as we delve into the heart of this enigma to unravel the reasons behind this backfiring spectacle. Understanding these quirks might just be the key to a smoother, more reliable power source for your needs.

Jump to a Specific Section

- 1 TLDR

- 2 Why Does My Portable Generator Backfire?

- 3 How to Fix a Backfiring Portable Generator?

- 4 What is the Difference between Backfire and Afterfire?

- 5 What Causes a Generator to Afterfire?

- 6 Generator Maintenance Tips

- 7 Generator Safety Tips

- 8 Conclusion

- 9 References

- 10 Frequently Asked Questions

- 10.1 What Type of Oil Should I Use in My Portable Generator?

- 10.2 How Much Fuel Should I Use in My Portable Generator?

- 10.3 Is It Safe to Leave My Portable Generator Running Overnight?

- 10.4 What Is the Expected Lifespan of a Portable Generator?

- 10.5 How Often Should I Change the Spark Plug in My Portable Generator?

- 10.6 How do you fix a backfire on a carburetor?

- 10.7 How do you fix a sputtering generator?

- 10.8 What causes engine backfire starting?

TLDR

- Backfiring in portable generators can be caused by incorrect fuel-air mixture, clogged spark arrestor, malfunctioning gas valves, inadequate or incorrect fueling, and carbon buildup.

- Troubleshooting steps for backfiring generators include checking fuel quality, cleaning or replacing spark plugs, inspecting hoses and connections for air leaks, inspecting timing belts or chains, and cleaning carburetor jets and passages.

- Preventative maintenance tips for portable generators include regularly checking spark plugs, inspecting air filters for dirt or debris, changing oil at least once a year, ensuring the fuel tank has enough gas, and cleaning both external and internal components.

- Regularly servicing portable generators has several benefits, such as ensuring efficient operation, extending the generator’s lifespan, reducing operating costs, maintaining safety protocols, and avoiding potential malfunctions.

Why Does My Portable Generator Backfire?

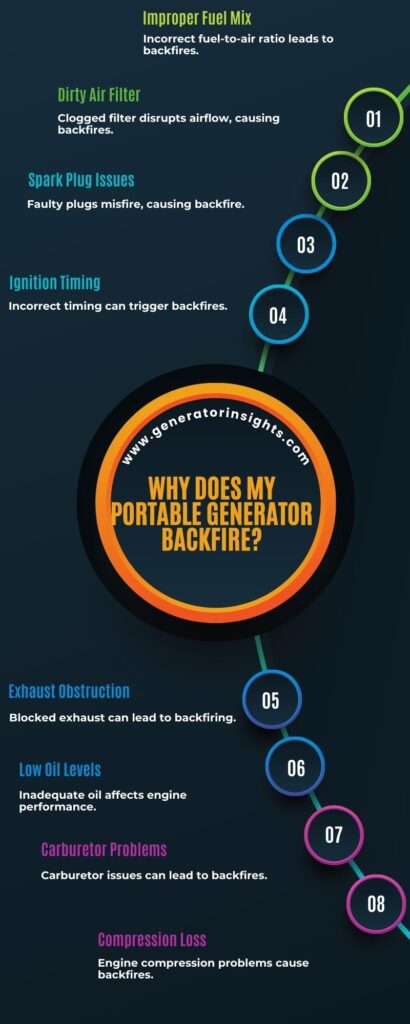

Backfiring in portable generators is commonly caused by a range of issues, such as incorrect fuel-air mixture, clogged spark arrestor, and malfunctioning gas valves. Following are some of the potential causes of a backfiring generator:

- Dirty Air Filter:

- A clogged air filter restricts airflow, leading to an improper air-fuel mixture and potential backfiring. Regularly cleaning and replacing the air filter is crucial.

- Fuel Quality Issues:

- Contaminated or stale fuel can result in uneven combustion, causing the generator to backfire. Ensure the use of fresh, high-quality fuel and consider adding a fuel stabilizer.

- Ignition Timing Problems:

- Incorrect ignition timing can disrupt the engine’s combustion sequence, leading to backfires. Ensure the ignition system is properly calibrated as per the manufacturer’s recommendations.

- Exhaust System Blockages:

- Blocked exhaust systems create excessive pressure, forcing the engine to backfire. Regularly inspect and clear any obstructions in the exhaust pathway.

- Spark Plug Issues:

- Fouled or damaged spark plugs can misfire, causing backfires. Regularly inspect and replace spark plugs, ensuring they are correctly gapped.

- Incorrect Valve Clearance:

- Improper valve clearance can affect engine performance. Check and adjust the valve clearance according to the manufacturer’s specifications.

- Governor Malfunction:

- A malfunctioning governor may fail to maintain a constant engine speed, leading to erratic combustion. Inspect and repair the governor mechanism as needed.

- Overloaded Generator:

- Exceeding the generator’s capacity may strain the engine, resulting in backfires. Ensure the load on the generator is within its specified limits.

- Carburetor Issues:

- Dirty or misadjusted carburetors can disrupt the air-fuel mixture. Regularly clean the carburetor and ensure it is properly tuned for optimal performance.

- Low Oil Level:

- Inadequate oil levels can lead to increased friction and heat, causing the engine to backfire. Regularly check and maintain the proper oil level.

Understanding these causes will help in diagnosing and addressing the backfiring issues with your portable generator.

How to Fix a Backfiring Portable Generator?

Here are some quick fixes for a backfiring portable generator:

- Dirty Air Filter:

- Regularly clean or replace the air filter to ensure proper airflow.

- Fuel Quality Issues:

- Use fresh, high-quality fuel and consider adding a fuel stabilizer to prevent contamination.

- Ignition Timing Problems:

- Calibrate the ignition timing according to the manufacturer’s recommendations.

- Exhaust System Blockages:

- Regularly inspect and clear any obstructions in the exhaust system.

- Spark Plug Issues:

- Inspect and replace fouled or damaged spark plugs, ensuring proper gapping.

- Incorrect Valve Clearance:

- Check and adjust the valve clearance according to the manufacturer’s specifications.

- Governor Malfunction:

- Inspect and repair the governor mechanism to ensure it maintains a constant engine speed.

- Overloaded Generator:

- Avoid exceeding the generator’s capacity; ensure the load is within specified limits.

- Carburetor Issues:

- Regularly clean the carburetor and ensure it is properly tuned for the correct air-fuel mixture.

- Low Oil Level:

- Regularly check and maintain the proper oil level in the generator.

Addressing these fixes will help resolve the backfiring issues with your portable generator, ensuring optimal performance and longevity.

Now let’s discuss these fixes in detail.

Dirty Air Filter

A dirty air filter can impede the airflow into the generator’s engine, disrupting the air-fuel mixture and leading to backfiring. Regular maintenance of the air filter is crucial for optimal generator performance.

- Inspection:

- Begin by locating the air filter housing on your generator.

- Carefully remove the air filter from its housing.

- Assessment:

- Examine the air filter for dirt, dust, or debris. A clogged filter will appear dirty and may have visible particles.

- Cleaning:

- If the filter is reusable, clean it by gently tapping it to dislodge loose debris.

- For more thorough cleaning, use compressed air to blow out the trapped particles.

- Replacement:

- If the air filter is non-reusable or severely clogged, replace it with a new one.

- Ensure the replacement filter is compatible with your generator model.

- Regular Maintenance:

- Establish a routine for air filter maintenance based on the manufacturer’s recommendations.

- Regularly clean or replace the air filter to prevent future backfiring issues.

By following these steps and keeping the air filter clean, you can maintain proper airflow to the generator’s engine, minimizing the risk of backfiring and ensuring efficient operation.

Fuel Quality Issues

The quality of the fuel you use in your portable generator plays a crucial role in its performance. Contaminated or stale fuel can lead to uneven combustion and result in backfiring. Here’s a step-by-step guide to addressing fuel quality issues:

- Fuel Inspection:

- Regularly inspect the fuel in the generator’s tank for any signs of contamination or degradation.

- Check for water, sediment, or other impurities that may compromise fuel quality.

- Use High-Quality Fuel:

- Always use fresh, high-quality fuel from reputable sources.

- Consider using fuel stabilizers, especially if the generator is not used frequently.

- Tank Cleaning:

- If contamination is detected, drain the fuel tank carefully.

- Clean the tank thoroughly to remove any residue or impurities.

- Fuel Filter Replacement:

- Replace the fuel filter regularly to ensure it effectively filters out impurities.

- Refer to your generator’s manual for the recommended frequency of fuel filter replacement.

- Emptying the Carburetor:

- After extended periods of inactivity, consider emptying the carburetor to remove any stale fuel.

- This helps prevent the buildup of varnish or deposits that can affect combustion.

- Regular Maintenance:

- Establish a routine for fuel system maintenance, including tank checks and filter replacements.

- Adhering to a maintenance schedule will help prevent fuel-related backfiring issues.

By following these steps and maintaining high fuel quality, you can mitigate the risk of backfiring in your portable generator, ensuring reliable and efficient operation.

Ignition Timing Problems

Correct ignition timing is crucial for the proper functioning of a generator’s engine. Incorrect timing can disrupt the combustion sequence, leading to backfiring. Here’s a step-by-step guide to addressing ignition timing problems:

- Consult the Manual:

- Refer to your generator’s manual for specific information on the recommended ignition timing settings.

- Manufacturers provide precise instructions for adjusting timing based on engine models.

- Locate the Timing Marks:

- Identify the timing marks on the engine’s flywheel and the reference point on the engine casing.

- These marks are crucial for setting the ignition timing accurately.

- Adjustment Process:

- With the engine off, remove any covers necessary to access the flywheel and timing marks.

- Use a timing light to illuminate the marks and align them according to the specifications in the manual.

- Loosen and Adjust:

- If adjustment is needed, loosen the bolts securing the distributor or magneto.

- Adjust the position to align the timing marks correctly.

- Tighten and Recheck:

- Once the adjustment is made, securely tighten the bolts.

- Double-check the timing with the light to ensure accurate alignment.

- Regular Checks:

- Periodically check and recalibrate the ignition timing as part of routine generator maintenance.

- Changes in engine performance or unusual sounds may indicate the need for rechecking the timing.

- Professional Assistance:

- If unsure or uncomfortable adjusting the ignition timing, seek assistance from a professional or a qualified technician.

By carefully following these steps and adhering to the manufacturer’s specifications, you can maintain proper ignition timing, reducing the likelihood of backfiring in your portable generator.

Exhaust System Blockages

A blocked exhaust system can create excessive pressure within the engine, leading to backfiring in your portable generator. Here’s a step-by-step guide to addressing exhaust system blockages:

- Safety First:

- Before addressing the exhaust system, ensure the generator is turned off, and the engine has cooled down to prevent burns.

- Inspect the Exhaust Outlet:

- Check the exhaust outlet for any visible obstructions or debris.

- Remove any foreign objects that may have accumulated, restricting the exhaust flow.

- Inspect the Muffler:

- Examine the muffler for signs of damage, corrosion, or blockages.

- Clean or replace the muffler if necessary, following the manufacturer’s recommendations.

- Check Exhaust Pipes:

- Inspect the exhaust pipes for dents, bends, or other deformities that may impede the flow of exhaust gases.

- Straighten or replace damaged pipes as needed.

- Clear Carbon Buildup:

- Carbon buildup inside the exhaust system can restrict airflow.

- Use a suitable tool to carefully remove any carbon deposits, taking care not to damage the components.

- Inspect the Spark Arrester:

- If your generator has a spark arrester, check it for clogs or blockages.

- Clean or replace the spark arrester according to the manufacturer’s guidelines.

- Regular Maintenance:

- Incorporate regular checks of the exhaust system into your generator maintenance routine.

- Ensure that the entire exhaust pathway is clear of any hindrances.

- Professional Inspection:

- If you encounter persistent issues or are unsure about exhaust system maintenance, seek the assistance of a professional technician.

By systematically addressing these steps, you can maintain an unobstructed exhaust system, reducing the likelihood of backfiring in your portable generator and ensuring optimal performance.

Spark Plug Issues

Fouled or damaged spark plugs can lead to misfires and subsequent backfiring in your portable generator.

- Safety Precautions:

- Before starting any work, turn off the generator and allow it to cool to prevent burns.

- Disconnect the spark plug wire to ensure safety during inspection and replacement.

- Spark Plug Inspection:

- Remove the spark plug using a spark plug socket and inspect it for fouling, deposits, or damage.

- Look for signs of oil, carbon buildup, or electrode wear.

- Cleaning the Spark Plug:

- If the spark plug is only mildly fouled, you can attempt to clean it using a wire brush.

- Gently remove any deposits without damaging the electrode.

- Checking the Gap:

- Use a gap gauge to ensure the spark plug gap matches the specifications in the generator’s manual.

- Adjust the gap if necessary using a gap tool.

- Spark Plug Replacement:

- If the spark plug is excessively fouled, damaged, or worn, replace it with a new one.

- Ensure the replacement spark plug is of the correct type and heat range.

- Tightening the Spark Plug:

- Carefully thread the new or cleaned spark plug into the cylinder head by hand.

- Use a spark plug socket to tighten it to the specified torque.

- Reconnect the Wire:

- Reconnect the spark plug wire securely, ensuring a snug fit.

- Ensure there are no loose connections that could lead to misfires.

- Regular Checks:

- Include regular spark plug inspections and replacements in your generator maintenance schedule.

- Pay attention to any changes in engine performance, as they may indicate spark plug issues.

By following these steps, you can effectively address spark plug issues and minimize the risk of backfiring in your portable generator.

Incorrect Valve Clearance

Incorrect valve clearance can adversely affect the performance of your generator’s engine and lead to backfiring. Here’s a step-by-step guide to addressing incorrect valve clearance:

- Safety First:

- Prioritize safety by turning off the generator and allowing it to cool before attempting any maintenance on the engine.

- Locate the Valve Cover:

- Identify the valve cover on the engine, usually found on the top.

- Remove any components obstructing access to the valve cover.

- Access the Valves:

- Once the valve cover is exposed, locate the valves underneath.

- Different generators may have varying configurations, so consult your manual for specific guidance.

- Rotate the Engine:

- Rotate the engine by hand in the direction of normal operation until the valves are in the closed position.

- Refer to the manual for the correct procedure to avoid damaging the engine.

- Measure Valve Clearance:

- Use a feeler gauge to measure the clearance between the valve stem and the corresponding lifter or rocker arm.

- Refer to the manual for the specified valve clearance values.

- Adjustment Process:

- If the clearance is incorrect, you may need to adjust it by loosening the locknut and turning the adjustment screw.

- Follow the manual’s instructions carefully to achieve the correct clearance.

- Tighten Locknuts:

- Once the adjustment is made, tighten the locknuts to secure the correct valve clearance.

- Recheck the clearance to ensure it remains within the specified range.

- Repeat for Each Valve:

- Repeat the process for each valve in the engine, adjusting as necessary.

- Ensure consistent and correct valve clearance across all valves.

- Regular Maintenance:

- Include regular valve clearance checks and adjustments in your generator maintenance routine.

- Addressing valve clearance issues promptly can prevent backfiring and maintain engine efficiency.

By following these steps, you can address incorrect valve clearance and contribute to the smooth operation of your portable generator, reducing the likelihood of backfiring.

Governor Malfunction

A malfunctioning governor can result in erratic engine speed, leading to backfiring in your portable generator. Here’s a step-by-step guide to addressing governor malfunctions:

- Safety Precautions:

- Turn off the generator and allow it to cool before attempting any adjustments to ensure safety.

- Locate the Governor:

- Identify the governor mechanism on the engine. It’s often connected to the throttle linkage.

- Consult your generator’s manual for specific details on the governor’s location.

- Check for External Obstructions:

- Ensure that there are no external obstructions or debris hindering the governor’s movement.

- Clear any obstacles that may impede the governor’s proper operation.

- Inspect Governor Linkage:

- Examine the linkage connecting the governor to the throttle mechanism.

- Look for signs of wear, damage, or misalignment.

- Adjustment Check:

- Check the governor adjustment to ensure it falls within the manufacturer’s specified range.

- Follow the manual for guidelines on adjusting the governor if needed.

- Lubrication:

- Lubricate the governor linkage and moving parts according to the manufacturer’s recommendations.

- Proper lubrication helps ensure smooth and precise governor operation.

- Governor Spring Inspection:

- Inspect the governor spring for any signs of damage or weakness.

- Replace the spring if it appears worn out or damaged.

- Professional Assistance:

- If you are uncertain about governor adjustments or encounter persistent issues, seek the assistance of a professional technician.

- Governors are critical components, and adjustments should be made with precision.

- Regular Checks:

- Include regular checks of the governor mechanism in your generator maintenance routine.

- Early detection and correction of governor issues can prevent backfiring and maintain stable engine speed.

By following these steps, you can address governor malfunctions and contribute to the consistent and reliable performance of your portable generator, reducing the likelihood of backfiring.

Overloaded Generator

Exceeding the generator’s capacity can strain the engine, leading to backfiring.

- Understand Generator Capacity:

- Familiarize yourself with the maximum power output (wattage) your generator can handle.

- Check the generator’s manual or specifications for this information.

- Calculate Load Requirements:

- Determine the total wattage of the appliances and devices connected to the generator.

- Ensure the cumulative load is within the generator’s specified capacity.

- Prioritize Loads:

- Prioritize essential appliances and distribute the load evenly across the generator’s outlets.

- Avoid connecting devices that, when combined, exceed the generator’s capacity.

- Disconnect Excess Loads:

- If the generator is already running and you realize it’s overloaded, disconnect non-essential devices immediately.

- Gradually reconnect devices while monitoring the generator’s performance.

- Check the Wattage:

- Regularly check the wattage requirements of appliances and devices to prevent overloading.

- Some appliances may have high starting wattage, which should be considered.

- Use a Wattage Meter:

- Consider using a wattage meter to monitor real-time power usage and ensure it remains within safe limits.

- Generator Load Management:

- Implement load management strategies, such as staggering the startup of devices with high initial power requirements.

- This helps prevent sudden spikes in power demand.

- Educate Users:

- Ensure that anyone using the generator understands its capacity and the importance of load management.

- Educate users about the potential consequences of overloading.

- Regular Maintenance:

- Include checks of the generator’s load capacity in your routine maintenance.

- Periodically reassess your power needs to ensure they align with the generator’s capabilities.

By following these steps, you can effectively manage the load on your generator, preventing overloading and minimizing the risk of backfiring. This contributes to the generator’s longevity and reliable performance.

Carburetor Issues

Dirty or misadjusted carburetors can disrupt the air-fuel mixture, leading to backfiring in your portable generator. Here’s a step-by-step guide to addressing carburetor issues:

- Safety Precautions:

- Turn off the generator and allow it to cool before attempting any work on the carburetor.

- Locate the Carburetor:

- Identify the carburetor on the generator’s engine. It’s often situated near the air filter and throttle linkage.

- Refer to your generator’s manual for specific details on carburetor location.

- Air Filter Inspection:

- Check the air filter for cleanliness. A dirty air filter can contribute to carburetor issues.

- Clean or replace the air filter as necessary.

- Check for Fuel Contamination:

- Inspect the fuel in the carburetor for signs of contamination.

- Drain any old or contaminated fuel and replace it with fresh, clean fuel.

- Adjust the Carburetor:

- Refer to your generator’s manual for guidelines on carburetor adjustment.

- If the carburetor is adjustable, follow the specified settings for optimal air-fuel mixture.

- Cleaning the Carburetor:

- If the carburetor is dirty, clean it using carburetor cleaner and a soft brush.

- Remove any debris or varnish that may be affecting its performance.

- Inspect Fuel Lines:

- Check the fuel lines for clogs, kinks, or damage that may restrict fuel flow to the carburetor.

- Replace any damaged or compromised fuel lines.

- Fuel Bowl Inspection:

- If your carburetor has a fuel bowl, inspect it for sediment or debris.

- Clean the fuel bowl and ensure it’s free from any contaminants.

- Professional Assistance:

- If you’re uncomfortable or unsure about carburetor adjustments, seek assistance from a professional technician.

- Carburetors are sensitive components, and precise adjustments are crucial.

- Regular Maintenance:

- Incorporate regular carburetor checks and cleaning into your generator maintenance routine.

- Addressing carburetor issues promptly can prevent backfiring and maintain optimal engine performance.

By following these steps, you can effectively address carburetor issues and contribute to the smooth operation of your portable generator, reducing the likelihood of backfiring.

Low Oil Level

Maintaining an adequate oil level is crucial for the proper lubrication and functioning of your generator’s engine. Low oil levels can lead to increased friction and heat, potentially causing backfiring. Here’s a step-by-step guide to addressing low oil levels:

- Safety Precautions:

- Turn off the generator and allow it to cool before attempting to check or add oil.

- Ensure the generator is on a level surface for accurate oil level measurement.

- Locate the Oil Dipstick:

- Identify the oil dipstick on the generator, typically near the engine.

- Consult your generator’s manual for specific details on the dipstick location and oil type.

- Check Oil Level:

- Remove the dipstick and wipe it clean with a cloth or paper towel.

- Reinsert the dipstick fully, then withdraw it to check the oil level.

- Add Oil if Low:

- If the oil level is below the recommended range, add the appropriate type and grade of oil.

- Pour small amounts of oil at a time and recheck the level to avoid overfilling.

- Use Manufacturer-Recommended Oil:

- Refer to your generator’s manual for the manufacturer’s recommended oil type and viscosity.

- Using the correct oil ensures proper lubrication and engine protection.

- Check for Leaks:

- Inspect the generator for any signs of oil leaks around the engine or oil reservoir.

- Address any leaks promptly to prevent further oil loss.

- Oil Change Interval:

- Follow the recommended oil change intervals outlined in your generator’s manual.

- Regular oil changes help maintain optimal engine performance.

- Oil Filter Inspection:

- If your generator is equipped with an oil filter, inspect it during oil changes.

- Replace the oil filter as recommended by the manufacturer.

- Regular Oil Checks:

- Include regular oil level checks in your generator maintenance routine, especially before extended use.

- Maintaining the proper oil level is crucial for preventing engine issues, including backfiring.

By following these steps, you can ensure that your generator maintains an adequate oil level, promoting proper lubrication and reducing the risk of backfiring.

What is the Difference between Backfire and Afterfire?

When it comes to generators, understanding the nuances between terms like Backfire and Afterfire is crucial for maintaining and troubleshooting these power sources effectively.

Backfire

Backfire occurs when there’s a sudden ignition of the air-fuel mixture outside the combustion chamber, typically traveling backward into the intake system. This phenomenon often results from a momentary interruption in the combustion process. Preventing backfires is essential, as they can lead to damage to the generator’s components, such as the air filter or carburetor.

For instance, a generator may experience a backfire if the air-fuel mixture is too rich, leading to incomplete combustion. Regular maintenance, including checking and adjusting the fuel mixture, is vital to mitigate the risk of backfires.

Afterfire

In contrast, afterfire, also known as exhaust backfire, occurs when unburned fuel ignites in the exhaust system after the engine is shut down. This can happen due to a variety of reasons, such as a hot exhaust system or an overly rich fuel mixture. While afterfires are generally less harmful than backfires, they can still lead to issues like damaged mufflers or exhaust pipes.

To minimize the occurrence of afterfires, it’s important to ensure that the engine is running at the specified fuel-air ratio during operation. Additionally, allowing the generator to run for a short period before shutting it down can help burn off excess fuel, reducing the likelihood of afterfires.

In summary, backfire involves the ignition of the air-fuel mixture outside the combustion chamber, often caused by issues during combustion, while afterfire is the ignition of unburned fuel in the exhaust system after the generator is turned off. Understanding and addressing these phenomena are key to maintaining a generator’s longevity and optimal performance.

What Causes a Generator to Afterfire?

Afterfiring in generators can be a perplexing issue, disrupting smooth operations and indicating potential concerns. Understanding the causes of generator afterfiring is crucial for efficient troubleshooting and maintenance.

- Fuel Quality:

- Poor fuel quality can lead to incomplete combustion, causing afterfiring.

- Ensure the use of high-quality fuel to prevent residue buildup in the generator system.

- Ignition Timing:

- Incorrect ignition timing can result in firing after the exhaust stroke.

- Regularly check and adjust the ignition timing to maintain optimal performance.

- Exhaust Restrictions:

- Exhaust restrictions such as clogs or blockages can lead to increased back pressure.

- Regularly inspect and clean the exhaust system to prevent afterfiring issues.

- Air-Fuel Mixture:

- Imbalances in the air-fuel mixture can cause erratic combustion.

- Regularly calibrate the generator to ensure the correct ratio for efficient combustion.

- Spark Plugs:

- Worn-out or fouled spark plugs can contribute to afterfiring.

- Replace spark plugs regularly and follow the manufacturer’s recommendations for maintenance.

- Compression Issues:

- Reduced compression levels may lead to incomplete combustion.

- Periodically check and maintain proper compression levels in the generator engine.

- Excessive Carbon Deposits:

- Carbon deposits on engine components can affect combustion.

- Use fuel additives and perform regular engine cleaning to minimize carbon buildup.

- Governor Malfunctions:

- Malfunctions in the governor system can result in irregular engine speed.

- Regularly inspect and maintain the governor to ensure stable engine operation.

Understanding and addressing these key factors will help mitigate the occurrence of afterfiring in generators, ensuring reliable and efficient performance.

Generator Maintenance Tips

Ensuring your generator runs smoothly is crucial for uninterrupted power supply. Regular maintenance not only extends its lifespan but also prevents costly breakdowns. Here are essential tips to keep your generator in peak condition:

- Scheduled Inspections: Conduct thorough visual inspections every month, checking for loose wires, leaks, and any signs of wear and tear.

- Oil Level Check: Regularly monitor the oil levels. Low oil can lead to engine damage. Follow the manufacturer’s guidelines for the correct oil type and change intervals.

- Air Filter Replacement: Clean or replace the air filter as recommended by the manufacturer. A clogged filter reduces efficiency and can strain the generator.

- Fuel System Maintenance: Ensure the fuel system is clean and free of contaminants. Use a fuel stabilizer if the generator is not in frequent use to prevent fuel degradation.

- Battery Inspection: Check the battery terminals for corrosion and ensure they are tightly connected. Weak batteries can hinder starting and overall performance.

- Cooling System Care: Inspect the cooling system for debris and make sure the radiator fins are clean. Overheating can cause serious damage to the generator.

- Run the Generator Monthly: Even if there’s no power outage, run the generator for a short period each month. This keeps internal parts lubricated and ensures it’s ready when needed.

- Keep a Log: Maintain a maintenance log, noting each inspection, oil change, and part replacement. This log helps in tracking the generator’s health and aids in timely preventive measures.

Following these generator maintenance tips diligently ensures that your power backup system is reliable and ready to serve when required.

Generator Safety Tips

Generators are invaluable during power outages, but it’s crucial to prioritize safety. Follow these tips to ensure the proper and secure use of your generator:

- Outdoor Placement: Always operate your generator outdoors to prevent the buildup of harmful fumes. Maintain a safe distance from windows and doors.

- Ventilation: Adequate ventilation is essential. Keep the generator in an open space to disperse exhaust fumes and reduce the risk of carbon monoxide poisoning.

- Dry Environment: Place the generator on a dry surface to avoid electrical hazards. Keep it away from puddles or wet areas to prevent the risk of electric shock.

- Grounding: Properly ground the generator to reduce the risk of electric shock. Follow the manufacturer’s guidelines for grounding procedures.

- Fuel Storage: Store fuel in approved containers in a cool, well-ventilated area, away from living spaces. Never store fuel near the generator while it’s running.

- Fire Safety: Keep a fire extinguisher nearby and know how to use it. Generator engines can get hot, and having a fire safety tool on hand is crucial.

- Carbon Monoxide Alarms: Install carbon monoxide alarms in your home, especially in sleeping areas. These detectors can provide early warnings if dangerous levels of carbon monoxide are detected.

- Turn Off Before Refueling: Always turn off the generator and let it cool down before refueling. Spilled fuel on hot engine parts can lead to fires.

- Extension Cords: Use only heavy-duty extension cords designed for outdoor use. Ensure they are in good condition and rated for the wattage of your generator.

- Regular Maintenance: Follow the manufacturer’s guidelines for maintenance. Regularly check oil levels, filters, and other components to keep the generator running smoothly.

Remember, prioritizing safety when using generators is essential for both your well-being and the longevity of your equipment.

Conclusion

In conclusion, Why Does My Portable Generator Backfire sheds light on a frequently encountered issue, demystifying the causes behind generator backfiring. By delving into fuel quality, carburetor adjustments, and ignition system health, you can effectively address this concern and ensure your generator runs optimally. Regular maintenance and timely interventions are key to preventing backfiring and extending the lifespan of your equipment.

Let this guide serve as your go-to resource, offering valuable insights and practical solutions. With the right knowledge, you can confidently troubleshoot and maintain your portable generator, ensuring it reliably provides the power you need, when you need it.

References

- Carbon monoxide poisoning from portable electrical generators

- Development and performance evaluation of sound proof enclosure for portable generators

- Study of the impact of operation distance of outdoor portable generators under different weather conditions

- Noise control of engine driven portable generator set

Frequently Asked Questions

What Type of Oil Should I Use in My Portable Generator?

When using a portable generator, it is important to check your owners manual for the correct type of oil. Avoid overfilling the oil and avoid using fuel additives as they can damage the engine. Always use fresh oil that meets or exceeds manufacturers standards for optimal performance and extended life.

How Much Fuel Should I Use in My Portable Generator?

It’s important to know the correct amount of fuel for optimal performance. Consider looking up the manufacturer’s suggested guidelines for your model, as well as advice from experts on what type of oil may be best. Taking these steps can ensure that your generator runs efficiently with minimal backfire.

Is It Safe to Leave My Portable Generator Running Overnight?

Leaving a portable generator running for extended periods of time can be done safely, provided the fuel consumption is monitored and exhaust fumes are kept to a minimum. Noise reduction should also be considered due to potential disturbances. Proper maintenance and use of the generator will ensure safety and security.

What Is the Expected Lifespan of a Portable Generator?

Providing preventative maintenance and properly storing fuel can extend the life of a portable generator. On average, a quality model that is regularly maintained should last up to 10 years. However, with proper care and attention, it’s possible for a generator to continue delivering reliable power for many more years.

How Often Should I Change the Spark Plug in My Portable Generator?

The sparkplug in a portable generator should be changed every 100 hours of use or yearly, whichever comes first. This is to ensure correct fuel mixture and air filter operation for optimal performance.

How do you fix a backfire on a carburetor?

To address a carburetor backfire, the engine speed should be gradually lowered. It’s advisable to adhere to fuel recommendations and consider using brands with low or no alcohol content. Optimal performance can be achieved by adjusting the carburetor. If backfiring persists, consulting the equipment manufacturer about increasing air volume to reduce engine temperature is recommended.

How do you fix a sputtering generator?

When dealing with a sputtering generator, first, ensure the tank has fresh fuel. Introduce a fuel system cleaner (such as Seafoam or Techron) into the tank. Start the generator and allow it to warm up, even if the operation is uneven. As it runs, spray carb cleaner into the carburetor to address any sputtering issues.

What causes engine backfire starting?

Engine backfire during startup can be attributed to bad ignition timing. If the spark timing is not precisely aligned, it may lead to premature firing before intake valves are closed or delayed firing after exhaust valves have opened. In such cases, the combustible air/fuel mixture in the exhaust or intake can result in a backfire.