In a world powered by constant innovation, the quest for reliable energy solutions has led us to the question: Are all inverter generators pure sine wave? Imagine the importance of having a power source that seamlessly aligns with the rhythm of our modern lives.

As we delve into the heart of this inquiry, we embark on a journey to understand not just the technicalities but also the impact on our daily experiences. The pulsating hum of a generator should harmonize with our expectations, and the answer to the sine wave conundrum might just hold the key to uninterrupted, high-quality power – an essential melody in our fast-paced symphony of life.

Jump to a Specific Section

- 1 Key Takeaways

- 2 What is an Inverter Generator and How Does It Work?

- 3 How Does an Inverter Generator Produce Energy?

- 4 What is Pure Sine Wave?

- 5 Are All Inverter Generators Pure Sine Wave?

- 6 Importance of Pure Sine Wave for Electronics

- 7 Different Types of Waveforms produced by Inverter Generators

- 8 Pure Sine Wave Vs Modified Sine Wave

- 9 Benefits of Pure Sine Wave Inverter Generators

- 10 How to Convert Modified Sine Wave into Pure Sine Wave Inverter?

- 11 Factors to Consider When Buying an Inverter Generator

- 12 Pros and Cons of Inverter Generator

- 13 Troubleshooting Common Inverter Generator Issues

- 14 Inverter Generator Maintenance Tips

- 15 Inverter Generator Safety Tips

- 16 Conclusion

- 17 References

- 18 Frequently Asked Questions

- 18.1 Can a Modified Sine Wave Generator Damage Sensitive Electronics?

- 18.2 What Types of Appliances or Devices Require a Pure Sine Wave Generator?

- 18.3 Are There Any Advantages to Using a Modified Sine Wave Generator Over a Pure Sine Wave Generator?

- 18.4 How Do Inverter Generators Produce Different Types of Waveforms?

- 18.5 Are There Any Safety Concerns or Risks Associated With Using Inverter Generators?

- 18.6 How do you know if a generator is pure sine wave?

- 18.7 How do I know if my inverter is a pure sine wave inverter?

- 18.8 What is a square wave inverter?

Key Takeaways

- Pure sine wave generators are compatible with sensitive electronic devices and provide better power quality compared to those with modified sine wave output.

- Modified sine wave generators have limitations such as inability to power certain electronic devices, lack of stable voltage output leading to performance issues, and compatibility issues with devices designed for pure sine wave power.

- Adverse effects of irregular waveform on sensitive electronics include risks to device protection, increased power surge risks, reduced performance, overheating, and potential permanent damage.

- When choosing an inverter generator, factors to consider include power output, generator capacity, noise level, fuel efficiency, and additional features such as electric start, fuel efficiency modes, parallel operation capability, and built-in circuit protection.

What is an Inverter Generator and How Does It Work?

An inverter generator is a cutting-edge power solution that stands apart from traditional generators. Unlike its counterparts, an inverter generator employs advanced electronic circuitry to convert AC power to DC and then back to a stable AC output. This process ensures a consistent and clean flow of electricity, making it especially suitable for powering sensitive electronic devices.

Here’s how an inverter generator works:

- Voltage Control Mechanism:

- Inverter generators employ advanced electronic components to control voltage fluctuations during the power generation process.

- The generator initially produces AC (Alternating Current) power.

- Transformation to DC Power:

- The AC power generated is then directed through an inverter module, where it undergoes a transformation into DC (Direct Current) power.

- Inversion Back to AC:

- The crucial step involves inverting the DC power back to AC, but with a significant difference.

- Unlike conventional generators, the inverter generator maintains a finely controlled voltage during this inversion process.

- Precision in Voltage Control:

- The inverter technology allows for precise adjustments to the voltage output, ensuring a stable and consistent flow of electricity.

- This level of precision is a stark contrast to traditional generators that may exhibit voltage fluctuations.

- Elimination of Voltage Fluctuations:

- The finely controlled voltage eliminates the fluctuations typically associated with conventional generators.

- This characteristic makes inverter generators particularly suitable for powering sensitive electronic devices, as it minimizes the risk of voltage spikes or drops.

- Reliability and Safety:

- The elimination of voltage fluctuations contributes to the overall reliability of inverter generators.

- The finely tuned voltage control enhances the safety of connected devices, reducing the likelihood of damage due to irregular power supply.

In summary, the inverter generator’s operation involves a sophisticated process of controlling voltage fluctuations, transforming AC to DC, and then finely tuning the inverted power back to AC. This precision ensures a reliable and safe power source with minimal voltage variations, making it an ideal choice for various applications.

How Does an Inverter Generator Produce Energy?

Inverter generators are compact and efficient power sources that convert mechanical energy into electrical power. Unlike traditional generators, inverter generators produce clean and stable electricity. Let’s delve into the step-by-step process of how these generators generate energy:

- Fuel Combustion:

- Inverter generators typically use gasoline or propane as fuel.

- The fuel is injected into a combustion chamber, where it mixes with air.

- Engine Operation:

- The fuel-air mixture is ignited by a spark plug, initiating the engine’s operation.

- As the engine runs, it produces rotational mechanical energy.

- Alternator Function:

- The engine is connected to an alternator.

- The alternator converts the mechanical energy into alternating current (AC) electricity.

- AC to DC Conversion:

- The generated AC electricity passes through a rectifier. This component converts AC power into direct current (DC).

- Inverter Stage:

- The DC power is then sent to an inverter. The inverter plays a crucial role in the process.

- It inverts the DC power back into a stable and consistent AC power.

- Voltage Regulation:

- The inverter ensures the produced AC power has a consistent voltage and frequency.

- This results in a clean and stable sine wave output, suitable for powering sensitive electronic devices.

- Load Sensing:

- Inverter generators are designed with a load-sensing mechanism.

- This feature adjusts the engine speed based on the connected load, optimizing fuel efficiency.

In summary, an inverter generator combines fuel combustion, engine operation, alternator function, AC to DC conversion, inverter stage, and voltage regulation to produce reliable and clean electrical energy.

What is Pure Sine Wave?

Generators play a crucial role in providing electrical power when needed, especially during outages or in remote locations. One key aspect to consider is the type of waveform they produce, and a term commonly associated with this is the pure sine wave. Unlike other waveforms, such as square or modified sine waves, a pure sine wave mimics the smooth, undistorted pattern of electricity supplied by utilities. This means that the voltage smoothly transitions from positive to negative in a continuous manner.

Pure sine wave output is essential for powering sensitive electronics like laptops, smartphones, and certain appliances. The reason lies in the fact that these devices are designed to operate with a consistent and smooth flow of electricity. In contrast, generators producing non-sinusoidal waveforms may introduce harmonic distortions, potentially causing issues like overheating, malfunctions, or even permanent damage to sensitive electronics.

In practical terms, consider a scenario where you rely on a generator to power your computer. If the generator produces a pure sine wave, the power supplied to your computer will closely resemble that from a standard electrical outlet. On the other hand, if the generator outputs a distorted waveform, it could lead to erratic behavior or damage to your computer’s power supply and other components. Therefore, understanding the significance of a pure sine wave in generators is crucial for ensuring the reliable and safe operation of electronic devices in various applications.

Are All Inverter Generators Pure Sine Wave?

No, not all inverter generators generate a pure sine wave. While many modern models are designed to produce a pure sine wave, some may generate a modified or square wave instead. The difference lies in the smoothness and quality of the electrical signal. A pure sine wave is superior for powering devices with microprocessors, like laptops and smartphones, as it reduces the risk of damage and ensures optimal performance.

On the other hand, generators producing modified or square waves may be suitable for less sensitive equipment but can pose challenges with certain electronics.

For example, devices with motors or compressors may not function as efficiently on a non-pure sine wave output. Refrigerators, air conditioners, and power tools are examples of appliances that might experience issues with a modified or square wave.

Therefore, when choosing an inverter generator, it’s crucial to consider the type of waveform it produces, ensuring it aligns with the needs of the devices you intend to power.

Importance of Pure Sine Wave for Electronics

Let’s delve into the significance of a Pure Sine Wave for electronics.

- Stable Voltage Output:

- A Pure Sine Wave provides a smooth and consistent voltage output, mimicking the natural sinusoidal waveform of utility power.

- This stability prevents voltage fluctuations, safeguarding electronic devices from potential damage caused by sudden spikes or drops in voltage.

- Compatibility:

- Many electronic devices, especially sensitive ones like computers and audio equipment, are designed to operate on a Pure Sine Wave input.

- Incompatible waveforms, such as modified sine waves or square waves, may cause these devices to malfunction or experience reduced efficiency.

- Reduced Electromagnetic Interference:

- Pure sine wave inverters generate power with minimal harmonic distortion, resulting in lower electromagnetic interference.

- This is crucial for the proper functioning of electronic devices that may be susceptible to disruptions caused by electromagnetic noise.

- Motor Operation:

- Devices with electric motors, such as refrigerators and air conditioners, often require a Pure Sine Wave for smooth and efficient operation.

- Using other types of waveforms might lead to increased noise, heat generation, and reduced motor lifespan.

- Audio and Visual Equipment:

- Audio and video equipment, including amplifiers and televisions, benefit significantly from a Pure Sine Wave power source.

- These devices demand a clean power supply to deliver high-quality sound and images without distortions or flickering.

- Extended Device Lifespan:

- The smooth and consistent power provided by a pure sine wave contributes to the longevity of electronic devices.

- Uninterrupted, clean power reduces stress on components, minimizing wear and tear.

- Efficient Energy Conversion:

- Devices powered by pure sine wave inverters often exhibit higher energy efficiency.

- This efficiency is especially critical for renewable energy systems, where maximizing energy conversion is essential.

In summary, a Pure Sine Wave is crucial for electronics due to its stable voltage output, compatibility with a wide range of devices, reduced electromagnetic interference, optimal motor operation, and enhanced performance of audio and visual equipment. Choosing the right waveform ensures the longevity and reliability of electronic devices in various applications.

Different Types of Waveforms produced by Inverter Generators

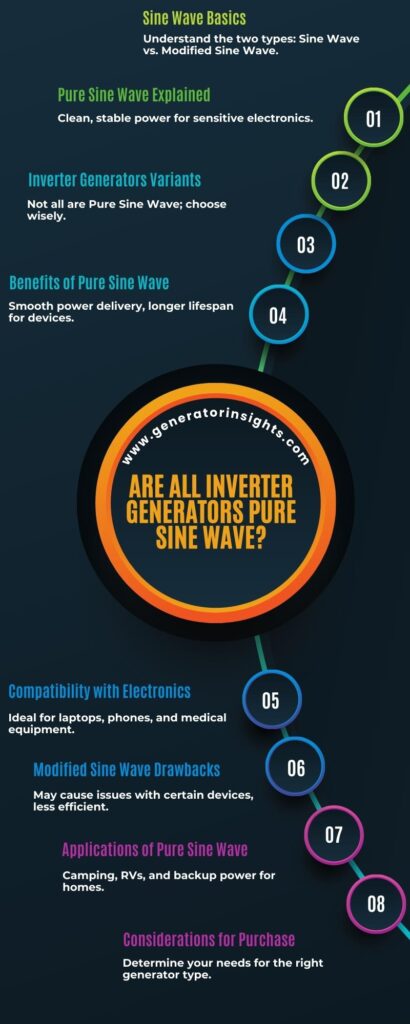

Inverter generators are known for their ability to produce clean and stable power. The type of waveform generated plays a crucial role in determining the quality of power output. There are mainly three types of waveforms associated with inverter generators:

| Waveform Type | Description | Application |

|---|---|---|

| Pure Sine Wave | Mimics the smooth and consistent waveform of household electrical grids. It ensures a steady flow of power, making it ideal for sensitive electronic devices like laptops and smartphones. Pure sine wave is considered the gold standard for power quality. | Used in homes, offices, and to power sensitive electronic equipment. |

| Modified Sine Wave | A stepped waveform that approximates a sine wave but with distinct steps. While cost-effective, it may cause issues with certain electronic devices due to its less smooth nature. | Commonly used for basic appliances and tools, but not recommended for sensitive electronics. |

| Square Wave | Characterized by rapid changes between maximum positive and negative voltage levels. This waveform is the simplest but least efficient, and it may cause humming or overheating in some devices. | Rarely used due to its potential to damage sensitive electronics; mainly found in older or less advanced inverter models. |

It’s important to choose an inverter generator with the appropriate waveform for your specific power needs. While pure sine wave inverters offer the highest quality power, modified sine wave inverters may suffice for simpler applications, and square wave inverters are generally best avoided for modern electronic devices.

Pure Sine Wave Vs Modified Sine Wave

A Pure Sine Wave inverter produces an electrical waveform that mirrors the smooth, undistorted curve of power provided by utility companies. It is considered the gold standard for delivering electricity, making it compatible with a wide range of electronic devices. Pure Sine Wave inverters are ideal for sensitive equipment like laptops, medical devices, and appliances with variable speed motors.

On the other hand, a Modified Sine Wave inverter generates a stepped waveform that approximates a sine wave. While it is more economical to produce, it introduces harmonic distortion, which may affect the performance of certain devices. Modified Sine Wave inverters are generally suitable for simple electronics and appliances like heaters, fans, and power tools, but they may cause issues with more sensitive equipment.

Here are the key differences between the two waveforms:

- Compatibility:

- Pure Sine Wave: Compatible with almost all electronic devices.

- Modified Sine Wave: May cause issues with sensitive electronics due to harmonic distortion.

- Performance:

- Pure Sine Wave: Provides clean and stable power, ensuring optimal performance for all connected devices.

- Modified Sine Wave: Can lead to reduced efficiency and potential malfunctions in some devices.

- Price:

- Pure Sine Wave: Generally more expensive due to the advanced technology used.

- Modified Sine Wave: Cost-effective, making it a budget-friendly choice.

For instance, consider charging a laptop with a Pure Sine Wave inverter; it will deliver a smooth and consistent flow of power, maintaining the laptop’s performance and battery life. In contrast, using a Modified Sine Wave inverter may result in reduced efficiency and potential overheating issues.

In summary, the choice between Pure Sine Wave and Modified Sine Wave depends on the specific electronic devices you plan to power. For sensitive equipment, investing in a Pure Sine Wave inverter is advisable to ensure reliable and efficient operation.

Benefits of Pure Sine Wave Inverter Generators

Inverter generators have become popular for providing portable power in various applications. One key feature that sets some apart is the ability to produce a pure sine wave output.

- Stable Power Supply:

- Unlike conventional generators, pure sine wave inverter generators produce a clean and stable electrical signal, similar to what you get from the electrical grid. This makes them ideal for powering sensitive electronics like laptops, smartphones, and medical equipment.

- Protection for Sensitive Devices:

- Devices with microprocessors or delicate electronic components, such as laptops and smart appliances, are more likely to operate efficiently and have an extended lifespan when powered by a pure sine wave. The smooth waveform prevents issues like overheating and damage to circuitry.

- Reduced Electrical Noise:

- Pure sine wave generators generate power with minimal harmonic distortion, resulting in lower electrical noise. This is crucial for audio equipment, communication devices, and other electronics that may be sensitive to interference.

- Compatibility with a Wide Range of Appliances:

- Many modern appliances and tools are designed to work optimally with a pure sine wave power source. Using a generator that produces a pure sine wave ensures compatibility with a broader range of devices, from basic household items to sophisticated electronics.

- Improved Motor Performance:

- Motors, particularly those in power tools and appliances like refrigerators, often operate more efficiently and with less noise when powered by a pure sine wave. The clean and smooth power output reduces the risk of motor overheating and extends the lifespan of these devices.

In summary, investing in a generator that produces a pure sine wave offers numerous benefits, especially if you have sensitive electronic devices or appliances that require a stable and clean power supply.

How to Convert Modified Sine Wave into Pure Sine Wave Inverter?

Converting a Modified Sine Wave Inverter into a Pure Sine Wave Inverter is essential for powering sensitive electronic devices without causing damage or performance issues. Here’s a step-by-step guide on how to achieve this:

- Understand the Difference:

- Recognize the distinction between a Modified Sine Wave and a Pure Sine Wave. A modified sine wave is a simpler waveform that may cause issues with certain appliances, while a pure sine wave mimics the smooth, continuous wave of household AC power.

- Identify the Modified Sine Wave Inverter:

- Locate the existing Modified Sine Wave Inverter that you want to convert. This could be in a standalone inverter or integrated into a power system.

- Research Suitable Pure Sine Wave Modules:

- Explore and select a Pure Sine Wave Inverter Module that matches the power rating and specifications of your modified inverter. Ensure it supports the load you intend to power.

- Disconnect Power Sources:

- Prior to any modifications, disconnect the modified inverter from the power source and ensure it is completely powered down to avoid any electrical hazards.

- Access the Inverter Internals:

- Open the casing of the modified sine wave inverter to access its internal components. This often involves removing screws or clips.

- Locate the Output Stage:

- Identify the section responsible for generating the output waveform. In many inverters, this involves finding the circuit responsible for waveform shaping.

- Remove the Modified Sine Wave Components:

- Carefully remove components related to the modified sine wave generation, such as capacitors, resistors, and shaping circuits. Refer to the inverter’s schematic or manual for guidance.

- Install the Pure Sine Wave Module:

- Connect the Pure Sine Wave Inverter Module in place of the removed components. Follow the module’s instructions to ensure correct wiring and connections.

- Secure Connections:

- Double-check all connections to ensure they are secure and correctly made. Loose connections can lead to inefficiencies or malfunctions.

- Close the Casing:

- Once the modifications are complete, securely close the inverter casing. Ensure there are no loose wires or components that could cause a short circuit.

- Test the Pure Sine Wave Output:

- Power up the inverter and test its output using an oscilloscope or a compatible device. Verify that the waveform now resembles a pure sine wave.

- Connect Appliances:

- Gradually reconnect and test electronic devices with sensitive components to confirm that they operate smoothly with the newly converted pure sine wave inverter.

Factors to Consider When Buying an Inverter Generator

Inverter generators are versatile power sources, ideal for various situations from camping trips to emergency backup power at home. Choosing the right one involves considering several key factors to ensure it meets your specific needs.

- Power Output: Determine your power requirements by listing the appliances and devices you plan to run simultaneously. Choose an inverter generator with a sufficient wattage to handle your peak load while providing a buffer for unexpected power spikes.

- Portability: Consider where and how you’ll be using the generator. If you need a portable option for camping or tailgating, a lightweight and compact design is crucial. Look for features like built-in handles and wheels for easy transportation.

- Fuel Efficiency: Inverter generators are known for their fuel efficiency. Look for a model with an economy mode that adjusts the engine speed based on the load, conserving fuel and reducing noise during lighter usage.

- Noise Level: Noise can be a significant concern, especially in camping or residential settings. Check the decibel (dB) rating to ensure the generator operates at an acceptable noise level. Generally, inverter generators are quieter than conventional ones.

- Clean Power Output: Inverter generators provide a stable and clean power output, making them suitable for sensitive electronics. Look for a unit with low total harmonic distortion (THD) to prevent damage to your devices.

- Runtime and Fuel Tank Capacity: Evaluate the generator’s runtime per tank of fuel and the capacity of the fuel tank. A longer runtime is beneficial for extended use, while a larger fuel tank reduces the frequency of refueling.

- Parallel Capability: Some inverter generators offer the ability to connect two units in parallel, effectively doubling the power output. This is valuable if your power needs may increase in the future, providing a scalable solution.

- Brand Reputation and Reviews: Research the reputation of different brands and read customer reviews. A reputable brand with positive feedback is more likely to offer a reliable and durable product.

- Warranty and Support: Check the warranty offered by the manufacturer. A longer warranty period indicates the manufacturer’s confidence in their product. Additionally, consider the availability of customer support and service centers.

- Price: While price is a crucial factor, it should not be the sole determining factor. Consider the overall value, factoring in features, reliability, and customer support.

Pros and Cons of Inverter Generator

Inverter generators have become popular for their portability and efficient power generation. Let’s explore the advantages and disadvantages of these generators.

Troubleshooting Common Inverter Generator Issues

Inverter generators are essential for reliable power in various settings. However, users may encounter issues that hinder their performance. Understanding and troubleshooting these common problems is crucial for maintaining optimal generator functionality.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| 1. Low Oil Level | Generator shutting down unexpectedly, abnormal engine noise. | Ensure that the oil level is within the recommended range. If low, add the appropriate oil type. Regularly check and change the oil according to the manufacturer’s guidelines. |

| 2. Spark Plug Issues | Difficulty starting, irregular engine operation. | Examine the spark plug for fouling or damage. Clean or replace it if necessary. Ensure the spark plug gap adheres to the manufacturer’s specifications. Regularly inspect and replace spark plugs based on usage and maintenance guidelines. |

| 3. Fuel System Problems | Poor engine performance, starting issues. | Confirm the fuel level and quality. Clean or replace the fuel filter regularly. Inspect the fuel lines for blockages. Ensure the fuel shut-off valve is open. Use fresh, stabilized fuel. Periodically clean the carburetor to prevent varnish buildup. |

| 4. Overloading | Generator shutting down during use, possible damage to appliances. | Check the generator’s wattage capacity and the combined wattage of connected devices. Avoid overloading by redistributing the load or disconnecting non-essential devices. Refer to the generator’s manual for the recommended load limits. |

| 5. Air Filter Clogs | Reduced power output, engine stalling. | Inspect and clean or replace the air filter regularly. A clogged filter can restrict airflow, affecting engine performance. Ensure proper seating of the air filter, and use the recommended filter type. |

| 6. Battery Issues | Electric start not working, insufficient power. | Check the battery voltage using a multimeter. Charge or replace the battery if voltage is low. Inspect and clean battery terminals. Ensure proper storage practices, such as charging the battery before extended periods of inactivity. |

| 7. Inverter Failure | Fluctuating power output, electrical anomalies. | Consult the manufacturer’s guide for inverter troubleshooting. Perform diagnostics using a multimeter. In case of malfunctions, seek professional repair services. Regularly inspect and maintain the inverter components as per the manufacturer’s guidelines. |

| 8. Engine Overheating | Generator shutting down due to overheating. | Check for obstructions around the engine and cooling system. Ensure proper ventilation. Monitor the ambient temperature and avoid running the generator in excessively hot conditions. Regularly clean the cooling fins and maintain proper oil levels. |

By addressing these common issues methodically, users can enhance the longevity and performance of their inverter generators. Regular maintenance and adherence to manufacturer guidelines play a crucial role in ensuring consistent power generation.

Inverter Generator Maintenance Tips

Ensure optimal performance and longevity of your inverter generator with these essential maintenance tips.

- Scheduled Oil Changes:

- Regularly change the oil as recommended by the manufacturer to maintain proper lubrication and extend the generator’s lifespan.

- Air Filter Inspection:

- Check the air filter routinely, cleaning or replacing it when needed, to prevent engine damage caused by dirt and debris.

- Spark Plug Care:

- Inspect and clean or replace the spark plug regularly to ensure efficient fuel combustion and prevent starting issues.

- Fuel System Maintenance:

- Stabilize the fuel when storing the generator for prolonged periods to prevent varnish buildup in the carburetor and fuel system.

- Battery Check:

- If your generator has a battery, check it for corrosion and maintain a full charge to ensure reliable starts during operation.

- Exhaust System Examination:

- Inspect the exhaust system for any leaks or blockages to maintain optimal engine performance and ensure safe operation.

- Cooling System Inspection:

- Check the cooling system, ensuring the radiator and cooling fins are clean to prevent overheating issues during prolonged use.

- Tighten Loose Parts:

- Regularly inspect and tighten loose nuts, bolts, and screws to prevent vibration-related damage and ensure overall stability.

- Run the Generator Regularly:

- Even if not in use, run the generator periodically to prevent fuel system issues and keep internal components lubricated.

- Store Properly:

- When storing the generator, keep it in a cool, dry place to prevent rust and corrosion, and use a cover to shield it from the elements.

Remember, a well-maintained inverter generator not only ensures reliable power but also extends its lifespan, saving you from costly repairs.

Inverter Generator Safety Tips

When it comes to operating inverter generators, prioritizing safety is paramount. Follow these essential tips to ensure a secure environment while harnessing the power of your generator:

- Positioning Matters:

- Optimal Placement: Place the inverter generator at least 20 feet away from your living or work area to prevent carbon monoxide exposure.

- Ventilation Awareness: Keep the generator in an open space with ample ventilation to dissipate exhaust gases effectively.

- Fueling Caution:

- No-Spill Rule: Refuel the generator only when it’s turned off to minimize the risk of spills.

- Use Fresh Fuel: Utilize fresh, stabilized fuel to maintain the generator’s efficiency and reduce emissions.

- Electrical Connection Safety:

- Proper Grounding: Ensure the generator is grounded correctly to avoid electrical hazards.

- Responsible Use of Extension Cords: Use heavy-duty, grounded extension cords designed for outdoor use to connect appliances.

- Regular Maintenance:

- Scheduled Checks: Perform regular checks on oil levels, air filters, and spark plugs to keep the generator in top condition.

- Follow Manufacturer’s Instructions: Adhere to the manufacturer’s maintenance guidelines for optimal performance.

- Emergency Shutdown Protocol:

- Immediate Response: Familiarize yourself with the emergency shutdown procedure to swiftly turn off the generator in case of any issues.

- Safety First: Prioritize your safety and that of others in case of emergencies.

By adhering to these inverter generator safety tips, you not only safeguard yourself and others but also extend the lifespan of your valuable equipment.

Conclusion

In conclusion, the distinction between pure sine wave and modified wave generators holds profound implications for various applications. As we’ve discovered, not all inverter generators produce a pure sine wave. This revelation emphasizes the importance of selecting the right generator for specific power needs. Whether for recreational use, home backup, or professional settings, choosing the right waveform ensures optimal performance and safeguards valuable electronics.

So, next time you ponder, Are all inverter generators pure sine wave remember, it’s a nuanced landscape. Prioritize precision in power supply and enjoy uninterrupted energy for all your critical endeavors.

References

- Development of micro power generators–a review

- Renewable energy systems with photovoltaic power generators: Operation and modeling

- High-power generators for offshore wind turbines

- Nationwide assessment of potential output from wind-powered generators

Frequently Asked Questions

Can a Modified Sine Wave Generator Damage Sensitive Electronics?

Modified sine wave generators can potentially damage sensitive electronics due to the irregular waveform they produce. To mitigate this risk, it is recommended to use pure sine wave generators for such devices. Non-sensitive electronics, however, can generally operate fine with modified sine wave power.

What Types of Appliances or Devices Require a Pure Sine Wave Generator?

Appliances and devices that require a pure sine wave generator include sensitive electronics such as laptops, televisions, and medical equipment. The advantages of using a pure sine wave generator include stable power output and protection against potential damage from a modified sine wave.

Are There Any Advantages to Using a Modified Sine Wave Generator Over a Pure Sine Wave Generator?

Advantages of using a modified sine wave generator over a pure sine wave generator include cost-effectiveness and compatibility with certain appliances. However, sensitive electronics may experience performance issues, and safety concerns arise due to the risk of damage to devices.

How Do Inverter Generators Produce Different Types of Waveforms?

Inverter generators produce different types of waveforms, including square wave and sine wave. The waveform quality and stability of an inverter generator is crucial for voltage regulation and to minimize waveform distortion and harmonic distortion.

Are There Any Safety Concerns or Risks Associated With Using Inverter Generators?

When considering the safety of using inverter generators, it is important to be aware of potential hazards and safety considerations. These generators can pose risks if not used correctly, leading to electrical accidents or carbon monoxide poisoning.

How do you know if a generator is pure sine wave?

When a box or oscillating fan is plugged into the generator, a modified sine wave will often result in a noticeable hum and weaker performance (RPMs) compared to utility power. Users can easily discern the difference in performance. If a seemingly low price raises suspicions, it might indicate a pure sine wave inverter.

How do I know if my inverter is a pure sine wave inverter?

The key distinction lies in the quality and characteristics of the AC waveform they generate. A pure sine wave inverter produces a smooth and regular waveform, closely resembling the ideal sine wave from the utility grid.

What is a square wave inverter?

Square wave inverters are primarily suitable for powering motors, while sine wave inverters are designed for household appliances like refrigerators, ovens, computers, and laptops. Square wave inverters, being less reliable, are considered unsafe for general appliance use, whereas sine wave inverters are regarded as highly safe.