In the world of power generation, the question often arises: do inverter generators need to be grounded? It’s a common query that echoes through the minds of those seeking a reliable power source. Picture this: you’re in the midst of a camping trip, or perhaps you’re preparing for a backyard event, and the reliability of your generator becomes paramount.

In this exploration of electrical safety and generator functionality, we’ll navigate the terrain of grounding, demystifying the importance while shedding light on whether your inverter generator dances to the rhythm of a grounded connection. So, let’s embark on this electrifying journey together.

Jump to a Specific Section

- 1 Key Takeaways

- 2 What is an Inverter Generator and How Does It Work?

- 3 What are the Basic Parts of an Inverter Generator?

- 4 What is Grounding?

- 5 Do Inverter Generators Need to Be Grounded?

- 6 What are Grounding Requirements for an Inverter Generator?

- 7 How to Ground an Inverter Generator?

- 8 Benefits of Grounding an Inverter Generator

- 9 Risks Associated with not Grounding Your Inverter Generator Properly

- 10 Troubleshooting Common Inverter Generator Grounding Issues

- 11 Tips to Properly Ground Your Inverter Generator

- 12 How to Properly Store Your Inverter Generator?

- 13 Inverter Generator Maintenance Tips

- 14 Inverter Generator Safety Tips

- 15 Conclusion

- 16 References

- 17 Frequently Asked Questions

- 17.1 Can I Use an Inverter Generator Indoors Without Grounding It?

- 17.2 Are There Any Potential Risks to Not Grounding an Inverter Generator?

- 17.3 Can I Use a Grounding Rod for My Inverter Generator if I Don’t Have Access to a Grounding Electrode System?

- 17.4 Is It Necessary to Ground an Inverter Generator if It Is Only Used for Short Periods of Time?

- 17.5 Are There Any Alternatives to Grounding an Inverter Generator That Provide the Same Level of Safety?

- 17.6 What happens if you don’t ground a portable generator?

- 17.7 Do you need to ground a generator if you use an extension cord?

- 17.8 Do Honda inverter generators need to be grounded?

Key Takeaways

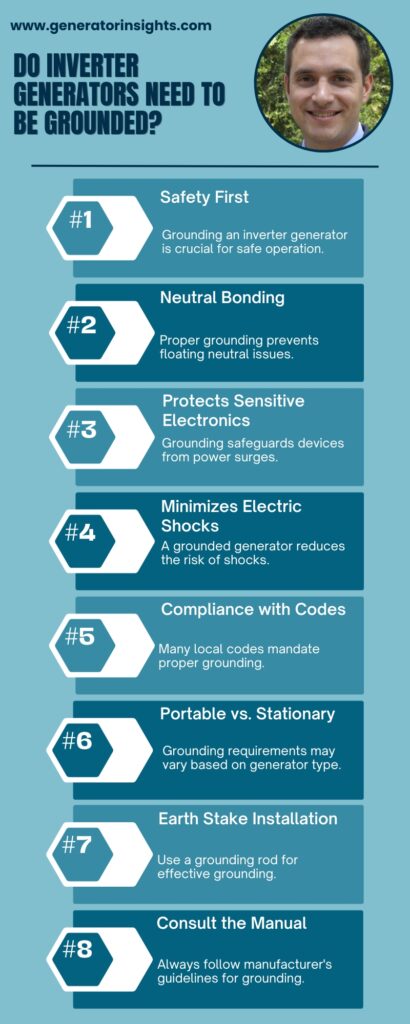

- Inverter generators must be grounded to ensure safety by providing a path for the dissipation of excess electrical energy.

- Proper grounding maintains a stable electrical environment, reducing the risk of electrical shocks and protecting connected equipment.

- Grounding is especially crucial in moist conditions, as it prevents electrical leakage and enhances the overall reliability of the inverter generator.

- Always follow the manufacturer’s guidelines and local electrical codes to ensure the correct and safe grounding of your inverter generator.

What is an Inverter Generator and How Does It Work?

An inverter generator is a cutting-edge power solution that stands apart from traditional generators. Unlike its counterparts, an inverter generator employs advanced electronic circuitry to convert AC power to DC and then back to a stable AC output. This process ensures a consistent and clean flow of electricity, making it especially suitable for powering sensitive electronic devices.

Here’s how an inverter generator works:

- Voltage Control Mechanism:

- Inverter generators employ advanced electronic components to control voltage fluctuations during the power generation process.

- The generator initially produces AC (Alternating Current) power.

- Transformation to DC Power:

- The AC power generated is then directed through an inverter module, where it undergoes a transformation into DC (Direct Current) power.

- Inversion Back to AC:

- The crucial step involves inverting the DC power back to AC, but with a significant difference.

- Unlike conventional generators, the inverter generator maintains a finely controlled voltage during this inversion process.

- Precision in Voltage Control:

- The inverter technology allows for precise adjustments to the voltage output, ensuring a stable and consistent flow of electricity.

- This level of precision is a stark contrast to traditional generators that may exhibit voltage fluctuations.

- Elimination of Voltage Fluctuations:

- The finely controlled voltage eliminates the fluctuations typically associated with conventional generators.

- This characteristic makes inverter generators particularly suitable for powering sensitive electronic devices, as it minimizes the risk of voltage spikes or drops.

- Reliability and Safety:

- The elimination of voltage fluctuations contributes to the overall reliability of inverter generators.

- The finely tuned voltage control enhances the safety of connected devices, reducing the likelihood of damage due to irregular power supply.

In summary, the inverter generator’s operation involves a sophisticated process of controlling voltage fluctuations, transforming AC to DC, and then finely tuning the inverted power back to AC. This precision ensures a reliable and safe power source with minimal voltage variations, making it an ideal choice for various applications.

What are the Basic Parts of an Inverter Generator?

Inverter generators play a crucial role in providing reliable and stable power, especially in remote locations or during power outages. Understanding the basic components of an inverter generator is essential for users seeking efficient and portable power solutions.

- Engine:

- The engine is the heart of an inverter generator, converting fuel into mechanical energy.

- A smaller, more fuel-efficient engine is a hallmark of inverter generators, ensuring optimal performance.

- Alternator:

- The alternator transforms mechanical energy from the engine into electrical energy.

- In inverter generators, advanced alternators produce clean and stable power, vital for sensitive electronics.

- Inverter Module:

- The inverter module is a key component responsible for converting raw electrical power into a stable AC output.

- This technology allows for a consistent power supply, crucial for electronic devices and appliances.

- Voltage Regulator:

- A built-in voltage regulator maintains a steady voltage output, preventing fluctuations that can damage devices.

- This feature enhances the reliability and safety of the power supply.

- Fuel Tank:

- The fuel tank stores the necessary fuel, typically gasoline or propane, to power the generator.

- Inverter generators are known for their fuel efficiency, providing extended run times on a single tank.

- Control Panel:

- The control panel offers user-friendly access to various functions such as starting, stopping, and monitoring.

- It may include features like fuel gauge, output indicators, and power outlets.

- Muffler:

- The muffler reduces noise produced by the generator, making inverter generators quieter compared to traditional models.

- This feature is valuable for both user comfort and environmental considerations.

- Casing and Frame:

- The generator’s casing and frame provide durability and protection for internal components.

- Sturdy construction ensures the generator can withstand the rigors of transportation and outdoor use.

What is Grounding?

Grounding refers to connecting certain parts of the generator system to the Earth, creating a pathway for electric current in case of a fault. This safety measure is essential to protect both people and equipment from potential hazards.

In a generator, various components such as the generator frame, housing, and certain conductive parts are typically grounded. The primary purpose of this is to provide a low-resistance path for fault currents to flow into the ground, minimizing the risk of electric shock and preventing equipment damage. By connecting the generator to the Earth, any unintended electrical leakage or short circuits are redirected away from people and assets.

For example, consider a portable generator commonly used during power outages. If the generator is not properly grounded and a fault occurs, such as a damaged electrical wire coming into contact with the generator frame, the entire generator could become electrified. However, with proper grounding, the fault current flows safely into the ground, reducing the risk of electric shock and ensuring the generator operates within safe limits.

In summary, grounding for a generator is a fundamental safety practice that involves connecting specific parts of the generator to the Earth, preventing electrical hazards and ensuring the safe operation of the equipment.

Do Inverter Generators Need to Be Grounded?

The short answer is yes, inverter generators need to be grounded. Grounding is a crucial safety measure that helps prevent electrical accidents and ensures the proper functioning of the generator.

Grounding involves connecting the generator to the earth through a conductor, typically a metal rod driven into the ground. This connection serves as a safety feature by providing a path for the dissipation of excess electrical energy, especially in the event of a fault or malfunction. Without proper grounding, there is an increased risk of electrical shock and fire hazards.

When an inverter generator is properly grounded, it helps maintain a stable electrical environment. The ground connection allows for the effective dissipation of stray currents, reducing the risk of electrical shocks to individuals and protecting connected equipment. In addition, grounding contributes to the overall reliability of the generator by minimizing the chances of voltage fluctuations and electrical interference.

In summary, grounding is a vital aspect of using inverter generators safely and efficiently. It is a simple yet effective measure that significantly reduces the risk of electrical accidents and enhances the overall reliability of the generator. Always follow the manufacturer’s guidelines and local electrical codes to ensure proper grounding, promoting a secure and trouble-free operation of your inverter generator.

What are Grounding Requirements for an Inverter Generator?

Inverter generators are valuable power sources, but ensuring their safe operation is crucial. Proper grounding is essential to prevent electrical hazards and protect both equipment and users. Here are the key grounding requirements for an inverter generator:

- Grounding Rod: Use a dedicated grounding rod, preferably made of copper, to create a direct connection between the generator and the earth. This rod should be securely installed at a specified depth to enhance conductivity.

- Wire Gauge: Employ a heavy-duty copper wire with an appropriate gauge for the grounding connection. Adequate wire thickness ensures low resistance, facilitating effective dissipation of excess electrical current into the ground.

- Separate Grounding System: Avoid sharing the generator’s grounding system with other electrical devices or structures. A dedicated system minimizes the risk of overloading and ensures the generator’s ground remains reliable.

- Regular Inspection: Periodically inspect the grounding system for any signs of wear, corrosion, or damage. A well-maintained grounding system guarantees continuous safety and proper functioning of the inverter generator.

- Connection to Generator Frame: Establish a direct connection between the grounding rod and the generator’s metal frame. This connection helps divert excess current to the ground, preventing the buildup of dangerous voltages.

How to Ground an Inverter Generator?

In order to ensure the safety of both yourself and your electrical equipment, it’s crucial to properly ground your inverter generator. Grounding helps prevent electrical shock and protects against potential damage to appliances. Here’s a step-by-step guide on how to ground an inverter generator:

- Understand the Importance of Grounding:

- Grounding provides a path for electrical currents to flow safely into the ground, preventing the buildup of excess voltage.

- It reduces the risk of electric shock and protects electronic devices from damage.

- Check Local Regulations:

- Consult your local electrical codes and regulations to ensure compliance with specific grounding requirements in your area.

- Select the Grounding Rod:

- Choose a copper grounding rod that meets the length requirements specified by local codes. A common length is 8 feet.

- Identify a Suitable Location:

- Place the grounding rod in an area with good conductivity, such as moist soil. Avoid rocky or sandy areas, as they may hinder effective grounding.

- Prepare the Grounding Rod:

- Remove any coatings or paint from the end of the grounding rod to ensure a solid electrical connection with the soil.

- Drive the Grounding Rod:

- Use a sledgehammer to drive the grounding rod into the ground until only a few inches are visible above the surface.

- Connect the Inverter Generator:

- Locate the grounding terminal on your inverter generator. It is usually marked with the symbol for Earth (⏚) or the word “Ground.”

- Use a Copper Wire:

- Attach a heavy-gauge, insulated copper wire from the grounding terminal of the generator to the grounding rod. Ensure a secure and tight connection.

- Minimize Sharp Bends:

- Keep the copper wire as straight as possible, minimizing sharp bends or kinks, to maintain a low-resistance pathway for electrical currents.

- Verify the Connection:

- Double-check that all connections are secure and tight. A loose connection can compromise the effectiveness of the grounding system.

- Test the Grounding:

- Use a grounding resistance tester to verify that the resistance between the grounding system and the earth is within acceptable limits, typically below 25 ohms.

- Periodic Inspections:

- Regularly inspect the grounding system for any signs of damage or corrosion. Make repairs or replacements as needed to ensure ongoing safety.

Remember, proper grounding is a crucial aspect of using an inverter generator safely. Always prioritize safety by following these steps and adhering to local regulations.

Benefits of Grounding an Inverter Generator

Inverter generators are valuable sources of portable power, especially in outdoor settings. Properly grounding these generators is crucial for safety and performance. Here are the key benefits of grounding an inverter generator:

- Enhanced Safety: Grounding reduces the risk of electric shock by providing a path for excess electrical currents to safely dissipate into the ground. This helps protect both people and equipment from potential harm.

- Stability of Voltage Output: Grounding contributes to a stable and reliable voltage output. It prevents voltage fluctuations and ensures a consistent power supply, which is essential for sensitive electronic devices like laptops, smartphones, and other gadgets.

- Protection Against Overloads: In the event of a fault or overload, grounding helps protect the generator by providing a route for excessive current to flow safely into the ground. This prevents damage to the generator’s internal components and extends its lifespan.

- Compliance with Safety Standards: Grounding is often a requirement to comply with safety standards and regulations. Following these guidelines not only ensures the safety of individuals using the generator but also avoids potential legal issues.

- Reduced Interference with Electronics: Proper grounding minimizes electromagnetic interference, which can affect the performance of nearby electronic devices. This is especially important when using the generator in conjunction with sensitive equipment.

- Prevention of Fire Hazards: Grounding reduces the risk of fire hazards associated with electrical malfunctions. By providing a controlled path for electrical currents, the likelihood of sparks or overheating is significantly diminished.

Risks Associated with not Grounding Your Inverter Generator Properly

Inverter generators are essential for providing portable power, but overlooking the importance of proper grounding can lead to various safety hazards and equipment issues. Here’s why grounding matters:

- Electric Shock Hazard: Without proper grounding, there’s an increased risk of electric shock when using the generator. This is because the ground connection helps dissipate excess electrical energy, preventing it from flowing into unintended paths.

- Equipment Damage: Inadequate grounding may result in damage to both the generator and connected devices. The excess electrical energy has the potential to harm the internal components of the generator and can also damage sensitive electronics and appliances.

- Fire Risk: Improperly grounded generators can pose a fire hazard. If there’s a malfunction or electrical fault, the lack of grounding makes it more difficult for excess electrical energy to dissipate safely, increasing the risk of overheating and fire.

- Reduced Generator Lifespan: Continuous operation without proper grounding can contribute to wear and tear on the generator’s internal components. This can shorten the overall lifespan of the equipment, leading to frequent breakdowns and the need for costly repairs or replacements.

- Legal and Safety Compliance: Many local regulations and safety standards mandate proper grounding for generators. Neglecting this requirement not only poses risks but may also result in legal consequences and fines. Ensuring compliance is crucial for the safety of both users and the community.

Remember, ensuring proper grounding is a simple yet crucial step in using inverter generators safely and efficiently. Always follow the manufacturer’s guidelines and local regulations to mitigate the associated risks.

Troubleshooting Common Inverter Generator Grounding Issues

Inverter generators play a crucial role in providing portable power, but issues related to grounding can occasionally arise, affecting their performance. Proper grounding is essential to ensure safety and efficient operation. Here are common issues and how to troubleshoot them:

| Issue | Possible Cause | Troubleshooting Steps |

|---|---|---|

| 1. Lack of Grounding | Inadequate or absent grounding connection. | Ensure the generator is connected to a grounding rod using a suitable grounding wire. |

| 2. Grounding Wire Damage | Damaged or frayed grounding wires. | Inspect the grounding wire for any visible damage and replace if necessary. |

| 3. Loose Grounding Connections | Poorly connected grounding components. | Tighten all grounding connections to ensure a secure and stable connection. |

| 4. Incorrect Grounding Rod Installation | Improper installation of the grounding rod. | Verify that the grounding rod is correctly installed at the recommended depth and angle. |

| 5. Grounding Rod Corrosion | Corrosion on the grounding rod or wire. | Clean the corrosion using a wire brush and apply an anti-corrosion solution if needed. |

| 6. Overloaded Grounding System | Excessive devices connected to the ground. | Limit the number of connected devices to prevent overloading the grounding system. |

Remember, a properly grounded inverter generator ensures a safe and reliable power source. Regular checks and maintenance can prevent these common issues and extend the lifespan of your generator.

Tips to Properly Ground Your Inverter Generator

Improper grounding of an inverter generator can pose safety risks and impact its performance. Here are essential tips to ensure safe and effective grounding:

- Use a Grounding Rod:

- Drive a copper grounding rod into the earth near the generator.

- Connect the generator’s grounding terminal to the rod using a heavy-duty copper wire.

- Check Ground Continuity:

- Ensure a low-resistance connection between the generator frame and the grounding rod.

- Periodically inspect the wire for wear or damage.

- Avoid Overloading:

- Do not overload the generator beyond its rated capacity.

- Excessive load can lead to overheating and compromise the effectiveness of the grounding system.

- Verify Power Cord:

- Use a 3-pronged power cord with a grounded plug for the generator.

- Avoid using adapters that eliminate the ground connection.

- Maintain Dry Conditions:

- Place the generator on a dry, level surface to prevent moisture interference.

- Moisture can reduce the efficiency of the grounding system.

- Periodic Checks:

- Regularly inspect the generator’s grounding components for wear and tear.

- Address any issues promptly to maintain a reliable ground connection.

How to Properly Store Your Inverter Generator?

Properly storing your inverter generator is crucial for maintaining its longevity and ensuring it’s ready to power up when you need it. A well-maintained generator is more reliable and efficient, so let’s delve into the key steps to store your inverter generator effectively.

- Clean the Generator:

- Remove debris and dust from the generator’s exterior using a soft brush.

- Wipe the surface with a damp cloth to prevent any dirt from settling during storage.

- Check and Change Oil:

- Verify the oil level and change it if needed.

- Fresh oil prevents corrosion and ensures smooth operation upon startup.

- Fuel System Considerations:

- Add a fuel stabilizer to the tank to prevent the formation of varnish and gum.

- Run the generator for a few minutes to allow the stabilizer to circulate through the fuel system.

- Battery Maintenance:

- Store in a Dry Location:

- Choose a cool, dry location for storage to prevent moisture-related issues.

- Use a breathable cover to protect the generator from dust while allowing proper ventilation.

- Ventilation:

- Ensure the storage area has proper ventilation to prevent the buildup of fumes.

- Avoid storing the generator in enclosed spaces to reduce the risk of carbon monoxide accumulation.

- Regular Maintenance Schedule:

- Establish a regular maintenance schedule even during periods of inactivity.

- Periodically start the generator and let it run for a short duration to keep internal components lubricated.

- Protect from Pests:

- Place mothballs or rodent repellent around the generator to deter pests.

- Inspect the generator periodically for any signs of pest activity.

- Secure from Theft:

- Consider securing the generator with a chain or lock to prevent theft.

- Store it in a location that is not easily accessible to unauthorized individuals.

- Documentation:

- Keep all user manuals and documentation in a safe place for reference.

- Note down the last maintenance date and any specific storage instructions provided by the manufacturer.

By following these steps, you’ll ensure that your inverter generator remains in optimal condition, ready to provide reliable power whenever you need it.

Inverter Generator Maintenance Tips

Ensure optimal performance and longevity of your inverter generator with these essential maintenance tips.

- Scheduled Oil Changes:

- Regularly change the oil as recommended by the manufacturer to maintain proper lubrication and extend the generator’s lifespan.

- Air Filter Inspection:

- Check the air filter routinely, cleaning or replacing it when needed, to prevent engine damage caused by dirt and debris.

- Spark Plug Care:

- Inspect and clean or replace the spark plug regularly to ensure efficient fuel combustion and prevent starting issues.

- Fuel System Maintenance:

- Stabilize the fuel when storing the generator for prolonged periods to prevent varnish buildup in the carburetor and fuel system.

- Battery Check:

- If your generator has a battery, check it for corrosion and maintain a full charge to ensure reliable starts during operation.

- Exhaust System Examination:

- Inspect the exhaust system for any leaks or blockages to maintain optimal engine performance and ensure safe operation.

- Cooling System Inspection:

- Check the cooling system, ensuring the radiator and cooling fins are clean to prevent overheating issues during prolonged use.

- Tighten Loose Parts:

- Regularly inspect and tighten loose nuts, bolts, and screws to prevent vibration-related damage and ensure overall stability.

- Run the Generator Regularly:

- Even if not in use, run the generator periodically to prevent fuel system issues and keep internal components lubricated.

- Store Properly:

- When storing the generator, keep it in a cool, dry place to prevent rust and corrosion, and use a cover to shield it from the elements.

Remember, a well-maintained inverter generator not only ensures reliable power but also extends its lifespan, saving you from costly repairs.

Inverter Generator Safety Tips

When it comes to operating inverter generators, prioritizing safety is paramount. Follow these essential tips to ensure a secure environment while harnessing the power of your generator:

- Positioning Matters:

- Optimal Placement: Place the inverter generator at least 20 feet away from your living or work area to prevent carbon monoxide exposure.

- Ventilation Awareness: Keep the generator in an open space with ample ventilation to dissipate exhaust gases effectively.

- Fueling Caution:

- No-Spill Rule: Refuel the generator only when it’s turned off to minimize the risk of spills.

- Use Fresh Fuel: Utilize fresh, stabilized fuel to maintain the generator’s efficiency and reduce emissions.

- Electrical Connection Safety:

- Proper Grounding: Ensure the generator is grounded correctly to avoid electrical hazards.

- Responsible Use of Extension Cords: Use heavy-duty, grounded extension cords designed for outdoor use to connect appliances.

- Regular Maintenance:

- Scheduled Checks: Perform regular checks on oil levels, air filters, and spark plugs to keep the generator in top condition.

- Follow Manufacturer’s Instructions: Adhere to the manufacturer’s maintenance guidelines for optimal performance.

- Emergency Shutdown Protocol:

- Immediate Response: Familiarize yourself with the emergency shutdown procedure to swiftly turn off the generator in case of any issues.

- Safety First: Prioritize your safety and that of others in case of emergencies.

By adhering to these inverter generator safety tips, you not only safeguard yourself and others but also extend the lifespan of your valuable equipment.

Conclusion

In conclusion, ensuring the proper grounding of your inverter generator is a fundamental step in guaranteeing its optimal functionality. Without a doubt, grounding plays a pivotal role in safeguarding both your equipment and the connected devices from potential electrical hazards.

By adhering to recommended guidelines, you not only enhance the longevity of your generator but also bolster safety measures. So, remember, when it comes to inverter generators, Do inverter generators need to be grounded? The answer is a resounding yes, for the sake of reliability, safety, and peace of mind.

References

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

- Stabilization of two electricity generators

Frequently Asked Questions

Can I Use an Inverter Generator Indoors Without Grounding It?

When using an inverter generator indoors, grounding is essential for safety. However, when using it outdoors, grounding requirements may vary depending on the specific type of generator. It is important to follow manufacturer guidelines and local electrical codes to ensure proper grounding.

Are There Any Potential Risks to Not Grounding an Inverter Generator?

Not grounding an inverter generator can pose potential risks to safety. Although there may be alternatives, grounding ensures stability and protects against electrical shocks. It is crucial to prioritize safety and follow proper guidelines.

Can I Use a Grounding Rod for My Inverter Generator if I Don’t Have Access to a Grounding Electrode System?

Using a grounding rod as an alternative for grounding an inverter generator can be a safe option if a grounding electrode system is not available. However, it is crucial to follow proper guidelines to ensure proper grounding and minimize the risk of electrical hazards.

Is It Necessary to Ground an Inverter Generator if It Is Only Used for Short Periods of Time?

Grounding requirements for inverter generators during long term use should be taken into consideration, as it can enhance overall performance. While grounding may not be necessary for short periods of time, it offers potential benefits for safety and stability.

Are There Any Alternatives to Grounding an Inverter Generator That Provide the Same Level of Safety?

There are alternatives to grounding an inverter generator that provide the same level of safety. These include using isolation transformers, using ground fault circuit interrupters (GFCIs), and implementing proper bonding and bonding conductors.

What happens if you don’t ground a portable generator?

Failure to ground a generator poses hazards, including the risk of electrical overload, which may damage the wiring or sensitive components unless the generator has overload protection. Additionally, there’s a danger of electrocution when coming into contact with ungrounded metal.

Do you need to ground a generator if you use an extension cord?

When relying solely on extension cords, there is no requirement to utilize a ground rod.

Do Honda inverter generators need to be grounded?

Most high-quality inverter generators, such as those from Honda and Yamaha, utilize a floating ground. It’s essential to note that without the neutral grounding plug, the generator may trip the protective device.