In the realm of power solutions, the question echoing through the minds of many is, Are inverter generators reliable? It’s a query that resonates with those seeking steadfast dependability in their energy sources. Picture this: you’re in the midst of an outdoor adventure, a vital project, or a storm-induced power outage, and reliability is not just a preference but a necessity.

Inverter generators promise a symphony of efficiency and innovation, but do they truly deliver on the trust we place in them? Join us on a journey where we unravel the reliability of these power companions, exploring the heartbeat of dependability that echoes through every surge and silence.

Jump to a Specific Section

- 1 Key Takeaways

- 2 What is an Inverter Generator and How Does It Work?

- 3 What are the Basic Parts of an Inverter Generator?

- 4 Are Inverter Generators Reliable?

- 5 What Makes an Inverter Generator Reliable?

- 6 How Does an Inverter Generator Produce Energy?

- 7 How to Run an Inverter Generator Safely?

- 8 How to Choose an Inverter Generator?

- 9 Pros and Cons of Inverter Generator

- 10 Troubleshooting Common Inverter Generator Issues

- 11 How to Properly Store Your Inverter Generator?

- 12 Inverter Generator Maintenance Tips

- 13 Inverter Generator Safety Tips

- 14 Conclusion

- 15 References

- 16 Frequently Asked Questions

- 16.1 How Often Should I Perform Maintenance on My Inverter Generator to Ensure Its Reliability?

- 16.2 Can I Use My Inverter Generator in Extreme Weather Conditions Such as Heavy Rain or Snow?

- 16.3 Are There Any Specific Steps I Should Take to Protect My Inverter Generator From Potential Damage During Transportation?

- 16.4 What Are the Most Common Issues That Can Arise With Inverter Generators, and How Can I Troubleshoot Them?

- 16.5 How Does the Reliability of Inverter Generators Compare to That of Conventional Generators in Terms of Long-Term Use and Performance?

- 16.6 What are the disadvantages of an inverter generator?

- 16.7 Is it worth getting an inverter generator?

- 16.8 What is better, a generator or inverter?

Key Takeaways

- Factors such as durability, quality of components, and design/engineering play a crucial role in determining the overall reliability of inverter generators.

- Inverter generators are designed to perform well in various weather conditions, including extreme temperatures, high humidity, and high altitudes.

- Durability and resistance to wear are important aspects of inverter generator reliability, with high-quality materials and advanced engine technology contributing to their longevity.

- Excessive noise levels in a generator can indicate mechanical problems or inefficiencies, leading to decreased reliability and potential breakdowns. Regular monitoring of noise levels is crucial.

What is an Inverter Generator and How Does It Work?

An inverter generator is a cutting-edge power solution that stands apart from traditional generators. Unlike its counterparts, an inverter generator employs advanced electronic circuitry to convert AC power to DC and then back to a stable AC output. This process ensures a consistent and clean flow of electricity, making it especially suitable for powering sensitive electronic devices.

Here’s how an inverter generator works:

- Voltage Control Mechanism:

- Inverter generators employ advanced electronic components to control voltage fluctuations during the power generation process.

- The generator initially produces AC (Alternating Current) power.

- Transformation to DC Power:

- The AC power generated is then directed through an inverter module, where it undergoes a transformation into DC (Direct Current) power.

- Inversion Back to AC:

- The crucial step involves inverting the DC power back to AC, but with a significant difference.

- Unlike conventional generators, the inverter generator maintains a finely controlled voltage during this inversion process.

- Precision in Voltage Control:

- The inverter technology allows for precise adjustments to the voltage output, ensuring a stable and consistent flow of electricity.

- This level of precision is a stark contrast to traditional generators that may exhibit voltage fluctuations.

- Elimination of Voltage Fluctuations:

- The finely controlled voltage eliminates the fluctuations typically associated with conventional generators.

- This characteristic makes inverter generators particularly suitable for powering sensitive electronic devices, as it minimizes the risk of voltage spikes or drops.

- Reliability and Safety:

- The elimination of voltage fluctuations contributes to the overall reliability of inverter generators.

- The finely tuned voltage control enhances the safety of connected devices, reducing the likelihood of damage due to irregular power supply.

In summary, the inverter generator’s operation involves a sophisticated process of controlling voltage fluctuations, transforming AC to DC, and then finely tuning the inverted power back to AC. This precision ensures a reliable and safe power source with minimal voltage variations, making it an ideal choice for various applications.

What are the Basic Parts of an Inverter Generator?

Inverter generators play a crucial role in providing reliable and stable power, especially in remote locations or during power outages. Understanding the basic components of an inverter generator is essential for users seeking efficient and portable power solutions.

- Engine:

- The engine is the heart of an inverter generator, converting fuel into mechanical energy.

- A smaller, more fuel-efficient engine is a hallmark of inverter generators, ensuring optimal performance.

- Alternator:

- The alternator transforms mechanical energy from the engine into electrical energy.

- In inverter generators, advanced alternators produce clean and stable power, vital for sensitive electronics.

- Inverter Module:

- The inverter module is a key component responsible for converting raw electrical power into a stable AC output.

- This technology allows for a consistent power supply, crucial for electronic devices and appliances.

- Voltage Regulator:

- A built-in voltage regulator maintains a steady voltage output, preventing fluctuations that can damage devices.

- This feature enhances the reliability and safety of the power supply.

- Fuel Tank:

- The fuel tank stores the necessary fuel, typically gasoline or propane, to power the generator.

- Inverter generators are known for their fuel efficiency, providing extended run times on a single tank.

- Control Panel:

- The control panel offers user-friendly access to various functions such as starting, stopping, and monitoring.

- It may include features like fuel gauge, output indicators, and power outlets.

- Muffler:

- The muffler reduces noise produced by the generator, making inverter generators quieter compared to traditional models.

- This feature is valuable for both user comfort and environmental considerations.

- Casing and Frame:

- The generator’s casing and frame provide durability and protection for internal components.

- Sturdy construction ensures the generator can withstand the rigors of transportation and outdoor use.

Are Inverter Generators Reliable?

Inverter generators have gained popularity in recent years due to their efficient and reliable power generation. These generators use advanced technology to produce clean and stable electricity, making them suitable for a wide range of applications. One key factor contributing to their reliability is their ability to produce consistent power, which is crucial for powering sensitive electronic devices like laptops and smartphones. Unlike traditional generators, inverter generators adjust their engine speed based on the power demand, resulting in reduced fuel consumption and lower noise levels. This adaptive feature enhances the generator’s lifespan by minimizing wear and tear associated with constant high-speed operation.

Additionally, inverter generators often come equipped with modern safety features, such as automatic shut-off in the event of low oil levels or overloading. These safeguards not only protect the generator itself but also prevent potential damage to connected appliances. Their compact and portable design further adds to their reliability, allowing users to easily transport and deploy them in various settings.

Thus, the adaptability, fuel efficiency, safety features, and reputable brand options make inverter generators a reliable choice for a diverse range of power needs.

What Makes an Inverter Generator Reliable?

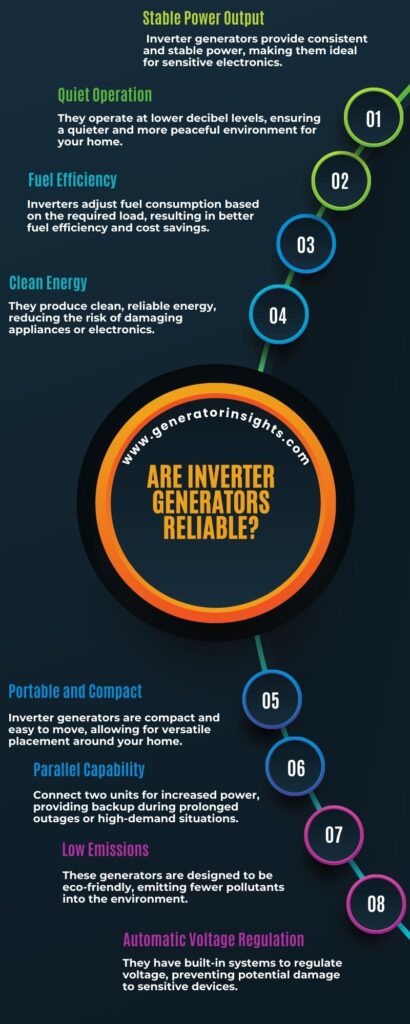

Inverter generators are known for their reliability, providing a stable power source in various situations. Understanding the key factors contributing to their dependability is crucial for making an informed choice.

- Stable Power Output: Inverter generators produce consistent and stable power, making them ideal for sensitive electronics. The inverter technology ensures a smooth sine wave output, preventing voltage fluctuations that could harm devices.

- Fuel Efficiency: Reliability often hinges on fuel efficiency. Inverter generators are designed to adjust their engine speed based on the required load, consuming only the necessary amount of fuel. This not only conserves energy but also extends the generator’s lifespan.

- Low Total Harmonic Distortion (THD): A reliable inverter generator maintains low THD, ensuring a clean power output. Low THD is critical for powering delicate electronics without risking damage. Look for generators with THD values below 3% for optimal performance.

- Quiet Operation: Reliability extends to user experience, and a generator that operates quietly is often more dependable. Look for models with noise levels below 60 decibels for minimal disturbance during use.

- Portability and Durability: A reliable inverter generator is both portable and durable. Compact designs and sturdy construction materials contribute to easy transport and longevity. Seek generators with robust build quality, such as those with reinforced frames and weather-resistant coatings.

- Advanced Safety Features: Safety is paramount in reliability. Look for generators equipped with features like automatic shut-off in case of low oil levels or overloading. These safety mechanisms protect the generator and connected devices.

- Brand Reputation: The reputation of the brand matters. Established and reputable brands often invest in research and development, ensuring their generators meet high standards. Customer reviews and ratings can provide insights into the real-world reliability of a specific model.

Understanding these key aspects will help you identify a reliable inverter generator that meets your specific needs.

How Does an Inverter Generator Produce Energy?

Inverter generators are compact and efficient power sources that convert mechanical energy into electrical power. Unlike traditional generators, inverter generators produce clean and stable electricity. Let’s delve into the step-by-step process of how these generators generate energy:

- Fuel Combustion:

- Inverter generators typically use gasoline or propane as fuel.

- The fuel is injected into a combustion chamber, where it mixes with air.

- Engine Operation:

- The fuel-air mixture is ignited by a spark plug, initiating the engine’s operation.

- As the engine runs, it produces rotational mechanical energy.

- Alternator Function:

- The engine is connected to an alternator.

- The alternator converts the mechanical energy into alternating current (AC) electricity.

- AC to DC Conversion:

- The generated AC electricity passes through a rectifier. This component converts AC power into direct current (DC).

- Inverter Stage:

- The DC power is then sent to an inverter. The inverter plays a crucial role in the process.

- It inverts the DC power back into a stable and consistent AC power.

- Voltage Regulation:

- The inverter ensures the produced AC power has a consistent voltage and frequency.

- This results in a clean and stable sine wave output, suitable for powering sensitive electronic devices.

- Load Sensing:

- Inverter generators are designed with a load-sensing mechanism.

- This feature adjusts the engine speed based on the connected load, optimizing fuel efficiency.

In summary, an inverter generator combines fuel combustion, engine operation, alternator function, AC to DC conversion, inverter stage, and voltage regulation to produce reliable and clean electrical energy.

How to Run an Inverter Generator Safely?

Running an inverter generator safely is crucial to ensure not only optimal performance but also the safety of yourself and those around you. Here’s a guide on how to run an inverter generator safely:

- Read the Manual:

- Before anything else, read the manufacturer’s manual thoroughly. It contains important information specific to your generator model, including safety guidelines and operational instructions.

- Outdoor Use Only:

- Always operate the inverter generator outdoors in a well-ventilated area. This prevents the buildup of harmful gases like carbon monoxide.

- Proper Fuel:

- Use the recommended fuel type mentioned in the manual. Usually, it’s unleaded gasoline. Avoid using old or contaminated fuel to ensure smooth operation.

- Grounding:

- Properly ground the generator according to the manufacturer’s instructions. This minimizes the risk of electric shock.

- Positioning:

- Place the generator on a flat, stable surface. This prevents any fuel leakage and ensures the generator operates efficiently.

- Cooling:

- Maintain proper ventilation around the generator to prevent overheating. Ensure there’s ample space for the hot air to dissipate.

- Load Management:

- Avoid overloading the generator. Check the manual for the maximum load capacity, and stay within those limits to prevent damage.

- Start-Up Sequence:

- Follow the correct start-up sequence provided in the manual. This usually involves turning on the generator first and then connecting your devices.

- Extension Cords:

- If using extension cords, make sure they are rated for outdoor use and have the correct power capacity. Using inadequate cords can lead to overheating and pose a fire hazard.

- Regular Maintenance:

- Perform regular maintenance tasks, such as oil changes and air filter replacements. This ensures the generator functions optimally and extends its lifespan.

- Shut Down Properly:

- When you’re done using the generator, allow it to cool down before turning it off. This helps prevent damage to the internal components.

Remember, always prioritize safety and adhere to the manufacturer’s guidelines for the specific inverter generator model you own.

How to Choose an Inverter Generator?

Inverter generators are versatile power sources, ideal for various situations from camping trips to emergency backup power at home. Choosing the right one involves considering several key factors to ensure it meets your specific needs.

- Power Output: Determine your power requirements by listing the appliances and devices you plan to run simultaneously. Choose an inverter generator with a sufficient wattage to handle your peak load while providing a buffer for unexpected power spikes.

- Portability: Consider where and how you’ll be using the generator. If you need a portable option for camping or tailgating, a lightweight and compact design is crucial. Look for features like built-in handles and wheels for easy transportation.

- Fuel Efficiency: Inverter generators are known for their fuel efficiency. Look for a model with an economy mode that adjusts the engine speed based on the load, conserving fuel and reducing noise during lighter usage.

- Noise Level: Noise can be a significant concern, especially in camping or residential settings. Check the decibel (dB) rating to ensure the generator operates at an acceptable noise level. Generally, inverter generators are quieter than conventional ones.

- Clean Power Output: Inverter generators provide a stable and clean power output, making them suitable for sensitive electronics. Look for a unit with low total harmonic distortion (THD) to prevent damage to your devices.

- Runtime and Fuel Tank Capacity: Evaluate the generator’s runtime per tank of fuel and the capacity of the fuel tank. A longer runtime is beneficial for extended use, while a larger fuel tank reduces the frequency of refueling.

- Parallel Capability: Some inverter generators offer the ability to connect two units in parallel, effectively doubling the power output. This is valuable if your power needs may increase in the future, providing a scalable solution.

- Brand Reputation and Reviews: Research the reputation of different brands and read customer reviews. A reputable brand with positive feedback is more likely to offer a reliable and durable product.

- Warranty and Support: Check the warranty offered by the manufacturer. A longer warranty period indicates the manufacturer’s confidence in their product. Additionally, consider the availability of customer support and service centers.

- Price: While price is a crucial factor, it should not be the sole determining factor. Consider the overall value, factoring in features, reliability, and customer support.

Pros and Cons of Inverter Generator

Inverter generators have become popular for their portability and efficient power generation. Let’s explore the advantages and disadvantages of these generators.

Troubleshooting Common Inverter Generator Issues

Inverter generators are essential for reliable power in various settings. However, users may encounter issues that hinder their performance. Understanding and troubleshooting these common problems is crucial for maintaining optimal generator functionality.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| 1. Low Oil Level | Generator shutting down unexpectedly, abnormal engine noise. | Ensure that the oil level is within the recommended range. If low, add the appropriate oil type. Regularly check and change the oil according to the manufacturer’s guidelines. |

| 2. Spark Plug Issues | Difficulty starting, irregular engine operation. | Examine the spark plug for fouling or damage. Clean or replace it if necessary. Ensure the spark plug gap adheres to the manufacturer’s specifications. Regularly inspect and replace spark plugs based on usage and maintenance guidelines. |

| 3. Fuel System Problems | Poor engine performance, starting issues. | Confirm the fuel level and quality. Clean or replace the fuel filter regularly. Inspect the fuel lines for blockages. Ensure the fuel shut-off valve is open. Use fresh, stabilized fuel. Periodically clean the carburetor to prevent varnish buildup. |

| 4. Overloading | Generator shutting down during use, possible damage to appliances. | Check the generator’s wattage capacity and the combined wattage of connected devices. Avoid overloading by redistributing the load or disconnecting non-essential devices. Refer to the generator’s manual for the recommended load limits. |

| 5. Air Filter Clogs | Reduced power output, engine stalling. | Inspect and clean or replace the air filter regularly. A clogged filter can restrict airflow, affecting engine performance. Ensure proper seating of the air filter, and use the recommended filter type. |

| 6. Battery Issues | Electric start not working, insufficient power. | Check the battery voltage using a multimeter. Charge or replace the battery if voltage is low. Inspect and clean battery terminals. Ensure proper storage practices, such as charging the battery before extended periods of inactivity. |

| 7. Inverter Failure | Fluctuating power output, electrical anomalies. | Consult the manufacturer’s guide for inverter troubleshooting. Perform diagnostics using a multimeter. In case of malfunctions, seek professional repair services. Regularly inspect and maintain the inverter components as per the manufacturer’s guidelines. |

| 8. Engine Overheating | Generator shutting down due to overheating. | Check for obstructions around the engine and cooling system. Ensure proper ventilation. Monitor the ambient temperature and avoid running the generator in excessively hot conditions. Regularly clean the cooling fins and maintain proper oil levels. |

By addressing these common issues methodically, users can enhance the longevity and performance of their inverter generators. Regular maintenance and adherence to manufacturer guidelines play a crucial role in ensuring consistent power generation.

How to Properly Store Your Inverter Generator?

Properly storing your inverter generator is crucial for maintaining its longevity and ensuring it’s ready to power up when you need it. A well-maintained generator is more reliable and efficient, so let’s delve into the key steps to store your inverter generator effectively.

- Clean the Generator:

- Remove debris and dust from the generator’s exterior using a soft brush.

- Wipe the surface with a damp cloth to prevent any dirt from settling during storage.

- Check and Change Oil:

- Verify the oil level and change it if needed.

- Fresh oil prevents corrosion and ensures smooth operation upon startup.

- Fuel System Considerations:

- Add a fuel stabilizer to the tank to prevent the formation of varnish and gum.

- Run the generator for a few minutes to allow the stabilizer to circulate through the fuel system.

- Battery Maintenance:

- For generators with electric starters, ensure the battery is fully charged.

- Consider removing the battery for long-term storage and keep it in a cool, dry place.

- Store in a Dry Location:

- Choose a cool, dry location for storage to prevent moisture-related issues.

- Use a breathable cover to protect the generator from dust while allowing proper ventilation.

- Ventilation:

- Ensure the storage area has proper ventilation to prevent the buildup of fumes.

- Avoid storing the generator in enclosed spaces to reduce the risk of carbon monoxide accumulation.

- Regular Maintenance Schedule:

- Establish a regular maintenance schedule even during periods of inactivity.

- Periodically start the generator and let it run for a short duration to keep internal components lubricated.

- Protect from Pests:

- Place mothballs or rodent repellent around the generator to deter pests.

- Inspect the generator periodically for any signs of pest activity.

- Secure from Theft:

- Consider securing the generator with a chain or lock to prevent theft.

- Store it in a location that is not easily accessible to unauthorized individuals.

- Documentation:

- Keep all user manuals and documentation in a safe place for reference.

- Note down the last maintenance date and any specific storage instructions provided by the manufacturer.

By following these steps, you’ll ensure that your inverter generator remains in optimal condition, ready to provide reliable power whenever you need it.

Inverter Generator Maintenance Tips

Ensure optimal performance and longevity of your inverter generator with these essential maintenance tips.

- Scheduled Oil Changes:

- Regularly change the oil as recommended by the manufacturer to maintain proper lubrication and extend the generator’s lifespan.

- Air Filter Inspection:

- Check the air filter routinely, cleaning or replacing it when needed, to prevent engine damage caused by dirt and debris.

- Spark Plug Care:

- Inspect and clean or replace the spark plug regularly to ensure efficient fuel combustion and prevent starting issues.

- Fuel System Maintenance:

- Stabilize the fuel when storing the generator for prolonged periods to prevent varnish buildup in the carburetor and fuel system.

- Battery Check:

- If your generator has a battery, check it for corrosion and maintain a full charge to ensure reliable starts during operation.

- Exhaust System Examination:

- Inspect the exhaust system for any leaks or blockages to maintain optimal engine performance and ensure safe operation.

- Cooling System Inspection:

- Check the cooling system, ensuring the radiator and cooling fins are clean to prevent overheating issues during prolonged use.

- Tighten Loose Parts:

- Regularly inspect and tighten loose nuts, bolts, and screws to prevent vibration-related damage and ensure overall stability.

- Run the Generator Regularly:

- Even if not in use, run the generator periodically to prevent fuel system issues and keep internal components lubricated.

- Store Properly:

- When storing the generator, keep it in a cool, dry place to prevent rust and corrosion, and use a cover to shield it from the elements.

Remember, a well-maintained inverter generator not only ensures reliable power but also extends its lifespan, saving you from costly repairs.

Inverter Generator Safety Tips

When it comes to operating inverter generators, prioritizing safety is paramount. Follow these essential tips to ensure a secure environment while harnessing the power of your generator:

- Positioning Matters:

- Optimal Placement: Place the inverter generator at least 20 feet away from your living or work area to prevent carbon monoxide exposure.

- Ventilation Awareness: Keep the generator in an open space with ample ventilation to dissipate exhaust gases effectively.

- Fueling Caution:

- No-Spill Rule: Refuel the generator only when it’s turned off to minimize the risk of spills.

- Use Fresh Fuel: Utilize fresh, stabilized fuel to maintain the generator’s efficiency and reduce emissions.

- Electrical Connection Safety:

- Proper Grounding: Ensure the generator is grounded correctly to avoid electrical hazards.

- Responsible Use of Extension Cords: Use heavy-duty, grounded extension cords designed for outdoor use to connect appliances.

- Regular Maintenance:

- Scheduled Checks: Perform regular checks on oil levels, air filters, and spark plugs to keep the generator in top condition.

- Follow Manufacturer’s Instructions: Adhere to the manufacturer’s maintenance guidelines for optimal performance.

- Emergency Shutdown Protocol:

- Immediate Response: Familiarize yourself with the emergency shutdown procedure to swiftly turn off the generator in case of any issues.

- Safety First: Prioritize your safety and that of others in case of emergencies.

By adhering to these inverter generator safety tips, you not only safeguard yourself and others but also extend the lifespan of your valuable equipment.

Conclusion

In conclusion, the answer to the question, Are inverter generators reliable resounds with a resounding affirmation. Their consistent power output, fuel efficiency, and low harmonic distortion make them an indispensable asset. From camping enthusiasts to homeowners preparing for unforeseen emergencies, the dependability of inverter generators ensures uninterrupted power supply.

So, when contemplating your power needs, consider the unwavering reliability that an inverter generator provides. With their advanced engineering and steadfast performance, these generators have indeed earned their reputation as a reliable power source for a multitude of applications. Embrace the confidence that comes with choosing an inverter generator for your power needs.

References

- Development of micro power generators–a review

- Renewable energy systems with photovoltaic power generators: Operation and modeling

- High-power generators for offshore wind turbines

- Nationwide assessment of potential output from wind-powered generators

Frequently Asked Questions

How Often Should I Perform Maintenance on My Inverter Generator to Ensure Its Reliability?

To ensure the reliability of your inverter generator, regular maintenance is crucial. This includes checking the fuel efficiency and noise levels, as well as conducting routine inspections and servicing as recommended by the manufacturer.

Can I Use My Inverter Generator in Extreme Weather Conditions Such as Heavy Rain or Snow?

Using an inverter generator in extreme weather conditions, such as heavy rain or snow, can have a significant impact on its performance and longevity. Proper storage and maintenance are crucial to ensure reliability and maximize the generator’s lifespan.

Are There Any Specific Steps I Should Take to Protect My Inverter Generator From Potential Damage During Transportation?

When transporting an inverter generator, it is important to take certain precautions to prevent damage. This includes securing the generator properly, checking fuel levels, and ensuring the unit is clean and free of debris. Regular maintenance is also essential for reliable performance.

What Are the Most Common Issues That Can Arise With Inverter Generators, and How Can I Troubleshoot Them?

When it comes to troubleshooting common issues with inverter generators, it is important to be aware of potential problems such as fuel system issues, electrical failures, and engine malfunctions. By following proper troubleshooting procedures, these issues can be addressed effectively.

How Does the Reliability of Inverter Generators Compare to That of Conventional Generators in Terms of Long-Term Use and Performance?

Inverter generators offer higher fuel efficiency and lower noise levels compared to conventional generators, making them a reliable choice for long-term use and performance. Their advanced technology ensures consistent power output and reduced maintenance requirements.

What are the disadvantages of an inverter generator?

Inverter generators come with a higher price tag compared to conventional generators. Additionally, their power output is notably lower than that of standard AC generators. It’s important to note that inverter generators, which run on gasoline, are not safe for indoor use.

Is it worth getting an inverter generator?

Inverter generators offer several advantages, making them a worthwhile investment. They operate more quietly than traditional portable generators, boast higher fuel efficiency, and provide cleaner power. This is especially beneficial when powering sensitive electronic devices or medical equipment.

What is better, a generator or inverter?

For those seeking a robust power source with high capacity, a generator is recommended, as it can handle heavy loads effectively. Inverters, on the other hand, may run out of energy when their connected batteries are depleted. Generators can run continuously with fuel replenishment, offering a more sustained power supply.