In a world that constantly demands flexibility and mobility, portable generators have become indispensable companions. As we delve into the realm of these power-packed saviors, a common question echoes – do portable generators need oil?

Picture this: you’re out in the great outdoors, a camping adventure, or facing an unexpected power outage. Your trusty portable generator stands ready to bridge the gap between darkness and illumination, silence and the comforting hum of electricity. Understanding the heartbeat of these portable powerhouses, including the crucial role of oil, is pivotal for ensuring they remain steadfast allies in our dynamic lives.

Jump to a Specific Section

- 1 Main Points

- 2 What Is a Portable Generator?

- 3 Do Portable Generators Need Oil?

- 4 What is the Need for Generator Oil?

- 5 Which Generator Parts Need Oil?

- 6 What are Different Types of Generator Oil?

- 7 How to Choose the Right Oil for Your Generator?

- 8 How to Check Oil Level of Your Generator?

- 9 How Often to Change Generator Oil?

- 10 How to Add Oil in Your Generator?

- 11 What Happens If You Use Too Little Oil?

- 12 What Happens If You Use Too Much Oil?

- 13 Conclusion

- 14 References

- 15 Frequently Asked Questions

- 15.1 What Safety Precautions Should Be Taken When Operating a Portable Generator?

- 15.2 How Often Should Oil Be Changed in a Portable Generator?

- 15.3 What Are the Most Common Causes of Breakdowns in Portable Generators?

- 15.4 Are There Any Environmental Considerations When Using a Portable Generator?

- 15.5 Are There Any Regulations or Laws That Apply to the Use of Portable Generators?

- 15.6 What oil do you use in a portable generator?

- 15.7 Do portable generators come with oil?

- 15.8 How do I know if my generator needs oil?

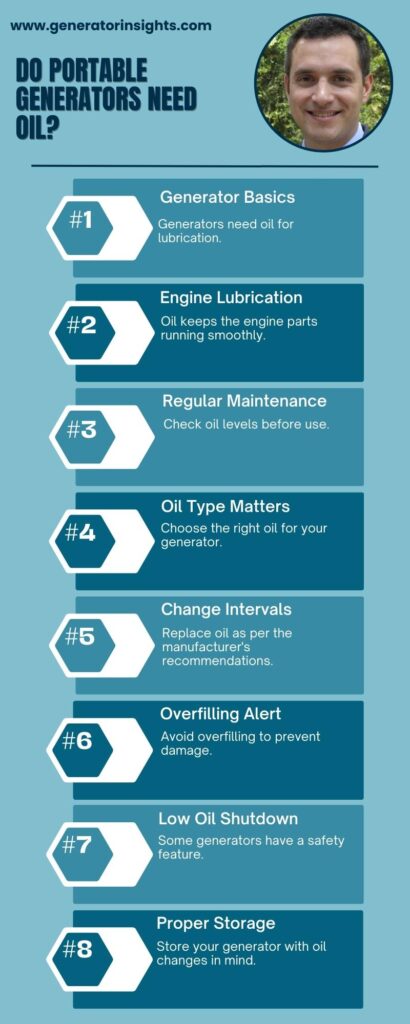

Main Points

- Portable generators require oil for proper lubrication of various parts such as fuel filters, pistons, bearings, and valves.

- The best type of oil for generators is one that meets or exceeds API Service Classification SF/SG/SH and has a viscosity grade of SAE 10W-30 or SAE 30.

- Regular oil changes according to manufacturer recommendations are essential for maintaining the generator’s performance and longevity.

- It is important to check oil levels regularly and add oil as needed, following proper procedures and safety precautions.

What Is a Portable Generator?

Portable generators are engine-driven electrical power sources that can be moved from one location to another. They provide a convenient source of energy when no other is available and have become an essential tool in many industries.

Portable generators are typically designed with fuel efficiency and noise reduction in mind, making them more accessible for everyday use. They come in a range of sizes and types, from small portable units to large industrial versions. The primary difference between the two is size; industrial models will usually be larger than portable variants and require more powerful engines which consume more fuel.

Portable generators also have additional features such as adjustable voltage settings, overload protection systems, low oil shutoff sensors, and surge protectors. All these components help ensure the safe operation of the generator regardless of its size or application.

Do Portable Generators Need Oil?

Yes, portable generators do require oil to function properly. Oil plays a crucial role in lubricating the engine’s moving parts, which helps reduce friction and heat generation. This, in turn, prolongs the lifespan of the generator and ensures it operates efficiently. Without sufficient oil, the engine can overheat and seize, potentially causing irreversible damage.

It’s essential to regularly check the oil level and quality, and to follow the manufacturer’s recommendations for oil type and change intervals. This basic maintenance practice ensures that the portable generator remains in optimal working condition and ready to provide power when needed.

What is the Need for Generator Oil?

- Lubrication: Generator oil plays a critical role in lubricating the engine components, reducing friction, and minimizing wear and tear. This is essential for the smooth operation and longevity of the generator.

- Heat Dissipation: As the generator operates, it generates heat. High-quality oil helps in dissipating this heat effectively, preventing the engine from overheating. Proper temperature regulation contributes to optimal performance and prevents damage.

- Sealant for Combustion Chamber: Generator oil acts as a sealant for the combustion chamber, preventing gas leakage and ensuring that the fuel-air mixture combusts efficiently. This enhances the overall combustion process and power generation.

- Cleansing Action: Generator oil has detergents and additives that help in cleaning the engine by removing contaminants and deposits. This cleansing action is crucial for maintaining the engine’s efficiency and preventing the buildup of sludge.

- Corrosion Prevention: The oil forms a protective layer on engine components, safeguarding them from corrosion and rust. This is particularly important in generators that may be exposed to varying weather conditions.

- Improved Fuel Efficiency: A well-lubricated engine provided by the right oil can lead to improved fuel efficiency. It ensures that the internal components move smoothly, reducing friction and optimizing the generator’s overall performance.

- Extended Engine Life: Regularly changing and using the correct type of oil contributes to the longevity of the generator. It protects vital components from excessive wear, reducing the likelihood of breakdowns and costly repairs.

- Reduced Emissions: Quality generator oil assists in burning fuel more cleanly, resulting in reduced emissions. This is not only environmentally friendly but also ensures compliance with emission standards and regulations.

- Enhanced Cold-Weather Performance: Some generator oils are designed to withstand cold temperatures, ensuring the engine starts smoothly even in challenging weather conditions. This is particularly important for generators used in regions with harsh winters.

Which Generator Parts Need Oil?

| Generator Part | Oil Requirement |

|---|---|

| Engine | Generators typically have an internal combustion engine that requires oil to lubricate moving parts and reduce friction. Regular oil changes are essential to maintain engine performance and longevity. Check the manufacturer’s specifications for the recommended oil type and change intervals. |

| Air Filter | While not directly related to oil, it’s worth noting that a clean air filter is crucial for optimal engine performance. Check and clean or replace the air filter regularly to ensure proper air intake, which indirectly contributes to the engine’s overall health. |

| Lubrication System | Some generators come equipped with additional components, such as a lubrication system, that may require their own oil reservoirs. Consult the generator’s manual to identify any specific parts or systems with separate oil needs. |

| Generator Head | The generator head, responsible for producing electrical power, may have its own oil requirements. This includes the bearings and other internal components. Regularly check and change the oil in the generator head according to the manufacturer’s recommendations. |

| Voltage Regulator | Certain generators feature a voltage regulator to ensure a steady and safe flow of electricity. Depending on the design, this component may have specific oil needs. Refer to the generator’s manual for guidance on maintaining the voltage regulator. |

Proper maintenance of these generator parts, including regular oil checks and changes, is crucial to ensure the generator operates efficiently and reliably. Always consult the manufacturer’s guidelines for specific recommendations tailored to your generator model.

What are Different Types of Generator Oil?

Understanding the various types of generator oil is crucial for ensuring optimal performance and longevity of your generator. Different generators may require specific types of oil, and choosing the right one contributes to efficient operation.

| Type of Generator Oil | Description | Advantages | Considerations | Viscosity Grades |

|---|---|---|---|---|

| Conventional Motor Oil | Traditional option for moderate conditions | Widely available, cost-effective | Requires regular monitoring and more frequent changes | Commonly available in various grades |

| Synthetic Motor Oil | Engineered for high-performance and extreme conditions | Superior lubrication, stability, extended change intervals | More expensive, but offers enhanced protection | Available in various grades, including 10W-30 |

| Bio-Based Oils | Derived from renewable sources, eco-friendly | Biodegradable, potential good performance | Availability and compatibility may vary | Varies, check product specifications |

| Multi-Viscosity Oil | Adapts to temperature changes, stable in various climates | Suitable for generators exposed to temperature variations | Regular checks still necessary | Available in various grades, e.g., 10W-30 |

| Single-Weight Oil | Consistent viscosity across a specific temperature range | Simple and effective in stable environments | May require more attention in extreme climates | Less common in multi-weight grades |

| High Mileage Oil | Formulated for older generators or those with higher usage | Addresses wear and aging concerns | Compatibility with specific models should be verified | Available in various grades |

| Viscosity Grades (e.g., 10W-30) | Indicates oil’s flow characteristics at different temperatures | 10W represents viscosity at low temperatures, 30 at high temperatures | Choose based on climate and engine specifications | Common grades include 10W-30, 5W-30, and 20W-50 |

How to Choose the Right Oil for Your Generator?

Selecting the appropriate oil for your generator is crucial for ensuring optimal performance, longevity, and reliability.

- Refer to the Manufacturer’s Manual:

- Check the manual for specific oil type and viscosity recommendations.

- Deviating from these guidelines may compromise the generator’s efficiency.

- Consider the Ambient Temperature:

- Different oils perform optimally in specific temperature ranges.

- Choose lower-viscosity oil for colder climates and higher-viscosity for warmer environments.

- Choose the Right Oil Type:

- Decide between conventional and synthetic oil based on your usage scenario and climate.

- Synthetic oil offers enhanced performance, especially in extreme temperatures.

- Multi-Viscosity Oils for Versatility:

- Consider using multi-viscosity oils (e.g., 10W-30 or 5W-30) for diverse weather conditions.

- The first number indicates viscosity in colder temperatures, and the second number represents viscosity at higher temperatures.

- Check for Additives:

- Look for oils with added detergents and stabilizers.

- Detergents prevent deposits, while stabilizers extend the oil’s lifespan.

- Regular Oil Checks and Changes:

- Establish a routine maintenance schedule based on manufacturer recommendations.

- Regular checks and changes ensure clean and effective lubrication of engine components.

- Seek Professional Advice:

- If uncertain, consult local mechanics or the generator manufacturer’s customer support.

- Professional advice can provide tailored insights for specific operating conditions.

How to Check Oil Level of Your Generator?

Maintaining the proper oil level in your generator is paramount for its optimal performance and longevity. Regularly checking the oil ensures that the engine is adequately lubricated, reducing the risk of damage and enhancing overall efficiency.

- Preparation:

- Ensure the generator is turned off and has cooled down.

- Perform the check on a level surface for accurate readings.

- Locate the Oil Dipstick:

- Identify the brightly colored rod with a loop or handle.

- Remove and Wipe the Dipstick:

- Take out the dipstick and wipe it clean with a cloth.

- Ensure a clean surface for an accurate reading.

- Reinsert the Dipstick:

- Carefully reinsert the dipstick into its tube until fully seated.

- Pull it out again to examine the oil level.

- Check the Oil Level:

- Observe markings on the dipstick indicating the proper oil level range.

- Ensure the oil falls between the “low” and “full” marks.

- Adding Oil:

- If the level is below “low,” add recommended oil type incrementally.

- Allow time for the oil to settle before rechecking.

- Avoid overfilling to prevent engine issues.

- Repeat Regularly:

- Make oil level checks a routine part of generator maintenance.

- Inspect before each use, especially during extended operation.

- Follow Manufacturer’s Guidelines:

- Refer to the generator’s manual for specific instructions.

- Follow recommendations for oil type, change intervals, and unique procedures.

Regularly monitoring and maintaining the proper oil level in your generator ensures reliability and contributes to its long-term functionality. By following these steps diligently, you can confidently keep your generator in optimal condition, ready to provide reliable power when needed.

How Often to Change Generator Oil?

Maintaining the proper oil change schedule is a pivotal aspect of ensuring the longevity and efficiency of your generator. The frequency at which you should change the oil depends on several factors, all of which contribute to the generator’s overall health and performance.

1. Operating Hours

The primary factor influencing the oil change interval is the number of operating hours the generator accrues. Manufacturers typically provide guidelines on the recommended hours of operation between oil changes. As a general rule of thumb, many experts suggest changing the oil every 50 to 100 hours of use for optimal performance.

2. Type of Oil

The type of oil you use in your generator also affects how often it needs to be changed. High-quality synthetic oils tend to have a longer lifespan compared to conventional oils. Be sure to consult the generator’s manual for the manufacturer’s recommendations on oil type and change intervals.

3. Environmental Conditions

The environmental conditions in which the generator operates play a role in determining the frequency of oil changes. If the generator operates in extreme temperatures, dusty environments, or experiences heavy loads frequently, more frequent oil changes may be necessary to combat increased wear and tear.

4. Regular Inspections

Performing regular inspections of the oil color and consistency is crucial in gauging the health of the generator. Dark, gritty, or sludgy oil may indicate contamination or deterioration, signaling the need for an oil change, even if the recommended hours of operation haven’t been reached.

5. Manufacturer Recommendations

Always refer to the manufacturer’s recommendations outlined in the generator’s manual. Manufacturers provide specific guidelines based on the design and engineering of the generator, ensuring optimal performance and longevity. Adhering to these guidelines is essential for warranty compliance and overall reliability.

How to Add Oil in Your Generator?

Adding oil to your generator is a straightforward yet vital task for proper maintenance. Start by consulting the user manual to determine the recommended oil type and quantity for your specific generator model. Typically, generators use multi-viscosity oil, such as 10W-30. Locate the oil fill cap and dipstick on the side of the engine.

Before adding oil, ensure the generator is turned off and has cooled down. Removing the oil fill cap with a wrench or by hand, use a funnel to pour the recommended oil gradually into the oil fill opening. Check the oil level periodically using the dipstick to prevent overfilling, which could lead to engine damage.

After adding oil, securely tighten the oil fill cap to prevent leaks or contaminants from entering the engine. Regularly checking and maintaining the oil level according to the manufacturer’s guidelines is essential for the generator’s proper functioning and longevity. This simple yet crucial maintenance task ensures your generator is ready to provide reliable power when needed.

What Happens If You Use Too Little Oil?

Maintaining the correct oil level in your generator is crucial for its optimal performance and longevity. If you use too little oil, several detrimental effects can occur. Inadequate lubrication can lead to increased friction and heat within the engine components, causing accelerated wear and potential damage. Insufficient oil may also compromise the engine’s ability to dissipate heat, leading to overheating issues.

Additionally, inadequate lubrication can result in decreased fuel efficiency and overall reduced generator performance. Therefore, it is essential to regularly check and maintain the proper oil level as specified in the manufacturer’s guidelines to ensure the reliable operation of your generator.

What Happens If You Use Too Much Oil?

Using too much oil in your generator can have detrimental effects on its performance and longevity. Overfilling the oil reservoir can lead to increased pressure within the engine, causing oil leaks and potential damage to seals and gaskets. The excess oil can also lead to frothing or aeration, reducing its lubricating effectiveness. This, in turn, may result in increased friction and heat, potentially causing engine components to wear out faster.

Furthermore, an overfilled oil level can lead to increased fuel consumption and, in extreme cases, engine misfires. The combustion process may be affected, leading to reduced power output and efficiency. It’s essential to adhere to the manufacturer’s recommended oil levels to ensure proper lubrication and prevent unnecessary strain on the generator’s engine.

If you suspect that you have added too much oil, it’s advisable to drain the excess and refill to the correct level as specified in the generator’s user manual. Regularly checking and maintaining the proper oil level is a fundamental aspect of generator care to ensure optimal performance and longevity.

Conclusion

In the realm of portable generators, one crucial question persists: Do Portable Generators Need Oil? As we’ve uncovered, proper lubrication is the lifeblood of these essential machines. Regular oil checks and changes are vital to maintain peak performance and extend the lifespan of your generator.

By adhering to manufacturer recommendations and conducting routine maintenance, you’ll ensure that your generator stands ready to provide power when it’s needed most. Let this guide serve as a valuable resource in your journey to generator ownership, empowering you to keep the lights on, even in the midst of unforeseen power outages.

References

- Carbon monoxide poisoning from portable electrical generators

- Development and performance evaluation of sound proof enclosure for portable generators

- Study of the impact of operation distance of outdoor portable generators under different weather conditions

- Noise control of engine driven portable generator set

Frequently Asked Questions

What Safety Precautions Should Be Taken When Operating a Portable Generator?

When operating a portable generator, it is essential to take fire prevention and fuel storage into consideration. Ensure the area is clear of combustible materials, never refuel while the engine is running, and store fuel in an approved container away from sources of ignition. Taking these safety precautions can help protect users and their environment.

How Often Should Oil Be Changed in a Portable Generator?

Fuel types and maintenance schedules should be regularly inspected when operating a portable generator to ensure oil is changed as necessary. This helps to keep the equipment in optimal condition for continued use.

What Are the Most Common Causes of Breakdowns in Portable Generators?

Common causes of breakdowns in portable generators include fuel contamination, air filter blockages and inadequate maintenance. Regular inspection of these components is essential to ensure optimal performance and prevent sudden malfunctions.

Are There Any Environmental Considerations When Using a Portable Generator?

Amidst the energy efficiencies and fuel types of a portable generator, environmental considerations must be taken into account. From emissions to safety protocols, these machines are capable of impacting their surrounding environment if used without caution. Thus, it is important to remain mindful when operating a portable generator.

Are There Any Regulations or Laws That Apply to the Use of Portable Generators?

Regulations and laws governing the use of portable generators vary from location to location. Generally, they include restrictions on fuel storage, noise levels, and other factors. It is important to be aware of applicable regulations when using a portable generator.

What oil do you use in a portable generator?

For temperatures above 32°F, use SAE 30; for temperatures between -10°F and 40°F, go for 10W-30. Synthetic 5W-30 works in all temperatures. Change the oil after the first 20-30 hours of use and every 100 hours thereafter.

Do portable generators come with oil?

No, it’s crucial to add generator motor oil before starting. The engine is usually shipped without oil. Check the oil level before starting, as running the generator without oil can damage the engine.

How do I know if my generator needs oil?

Experts recommend changing the oil every 50 to 200 hours. If used daily or continuously, change it every 50-100 hours. If used infrequently, you can wait longer, but always check the oil level regularly to ensure proper maintenance.