Embarking on the journey of synchronizing generators? Dive into the Generator Paralleling Guide, your compass in the realm of seamless power coordination. Ever found yourself in the midst of a blackout, yearning for an uninterrupted power flow? This guide is your ally, demystifying the intricacies of generator parallel operation. We understand the pulse of your power needs, and this guide is crafted with you in mind.

Uncover the secrets to synchronizing multiple generators effortlessly, empowering you to navigate power outages with confidence. Ready to wield the prowess of parallel generators? Let this guide illuminate your path to uninterrupted energy abundance.

Jump to a Specific Section

- 1 Core Lessons

- 2 What is a Generator and How It Works?

- 3 How Does a Generator Produce Power?

- 4 What is Paralleling?

- 5 Step-by-Step Generator Paralleling Guide

- 6 Why You Need to Parallel Generators?

- 7 How to Choose Generators for Parallel Operation?

- 8 How to Parallel Two Generators?

- 9 Can You Parallel Two Different Brand Inverter Generators?

- 10 Can You Parallel Two Different Size Inverter Generators?

- 11 Tips for Running Generators in Parallel

- 12 Common Mistakes to Avoid When Running Generators in Parallel

- 13 Troubleshooting Common Generator Paralleling Issues

- 14 Generator Maintenance Tips

- 15 Conclusion

- 16 References

- 17 Frequently Asked Questions

- 17.1 Can generators of different sizes and brands be paralleled together?

- 17.2 Is it possible to parallel generators with different fuel types?

- 17.3 How does generator paralleling affect the overall power quality?

- 17.4 What are the common challenges faced when paralleling generators?

- 17.5 Are there any limitations or restrictions when it comes to paralleling generators in certain environments or applications?

- 17.6 What are the steps in paralleling the generators?

- 17.7 Does paralleling generators double the wattage?

- 17.8 What are the requirements for connecting generators in parallel?

Core Lessons

- Generator Compatibility is Crucial: Ensure generators have matching make, model, kVA ratings, and voltage to guarantee seamless parallel operation.

- Precise Synchronization is Essential: Install automatic synchronizers and synchronize voltage regulators for consistent performance during parallel operation.

- Balanced Load Sharing is a Priority: Implement load-sharing modules to distribute the load evenly among generators, preventing overloading.

- Continuous Monitoring is Necessary: Regularly monitor voltage, frequency, and current parameters during parallel operation and employ automatic load shedding for system protection.

What is a Generator and How It Works?

A conventional generator, often referred to as an alternator, is a crucial component in the generation of electrical power. It plays a central role in converting mechanical energy into electrical energy. The fundamental principle behind its operation lies in Faraday’s law of electromagnetic induction.

In simple terms, when a coil of wire is rotated within a magnetic field, an electromotive force (EMF) is induced across the coil. This process is the key mechanism behind the functioning of a conventional generator. The magnetic field is typically created by a set of permanent magnets or an electromagnet.

To delve deeper into the working mechanism, as the coil rotates, it experiences a changing magnetic flux. According to Faraday’s law, this change induces an EMF in the coil. The induced EMF causes a flow of electric current within the coil, and this current is what we harness as electrical power.

The crucial components of a conventional generator include the rotor (rotating coil), stator (stationary coil), and a magnetic field source. The rotation of the rotor is often achieved by connecting it to a prime mover such as a turbine in a power plant or an engine in portable generators.

In the context of power plants, steam turbines are commonly used as the prime movers. The steam generated by burning fossil fuels or using other heat sources drives the turbine, which, in turn, rotates the rotor within the generator.

An illustrative example of a conventional generator is the one found in most automobiles. In a car’s alternator, the engine’s mechanical energy is used to turn the rotor within a magnetic field, producing the electrical power necessary to charge the battery and power various electrical systems in the vehicle.

In summary, a conventional generator converts mechanical energy into electrical energy through the principles of electromagnetic induction. Key components include the rotor, stator, and a magnetic field source. The rotational motion, usually driven by a prime mover, induces an electromotive force, resulting in the generation of electrical power.

How Does a Generator Produce Power?

Generators are devices that convert mechanical energy into electrical energy. They play a crucial role in power generation, providing electricity for various applications.

- Basic Components:

- Generators consist of a rotor (armature) and a stator.

- The rotor is a rotating part, while the stator is a stationary component.

- Mechanical Input:

- Mechanical energy, often derived from sources like steam, water, or wind, is applied to the rotor.

- This mechanical input causes the rotor to spin within the magnetic field created by the stator.

- Electromagnetic Induction:

- As the rotor spins, it cuts through the magnetic lines of flux produced by the stator.

- This cutting action induces an electromotive force (EMF) in the conductors of the rotor.

- Generation of Electric Current:

- The induced EMF drives the flow of electric current within the rotor windings.

- This current represents the conversion of mechanical energy into electrical energy.

- AC and DC Generators:

- AC generators produce alternating current, where the direction of the current periodically reverses.

- DC generators produce direct current, with a constant flow of current in one direction.

- Output Connection:

- The generated electrical energy is then transferred through output terminals for external use.

- In power plants, generators are often connected to the electrical grid to distribute electricity.

Understanding how generators work is essential for appreciating the foundational process behind the electricity that powers our homes, industries, and various technologies.

What is Paralleling?

Paralleling generators refers to the practice of connecting multiple power generators to operate together in a synchronized and coordinated manner. This is a common approach in power systems to achieve higher power output, enhance system reliability, and facilitate flexibility in managing loads. When generators are paralleled, they share the electrical load, with each generator contributing a portion of the total power required. This process is crucial for balancing the demand for electricity and ensuring a stable power supply.

To understand the concept better, imagine a scenario where a single generator is unable to meet the entire electricity demand of a facility or a community. In such cases, additional generators can be brought online and connected in parallel. The synchronization process involves matching the voltage, frequency, and phase angle of the incoming generator with those of the existing power supply. Once synchronized, the generators work together seamlessly, distributing the load effectively.

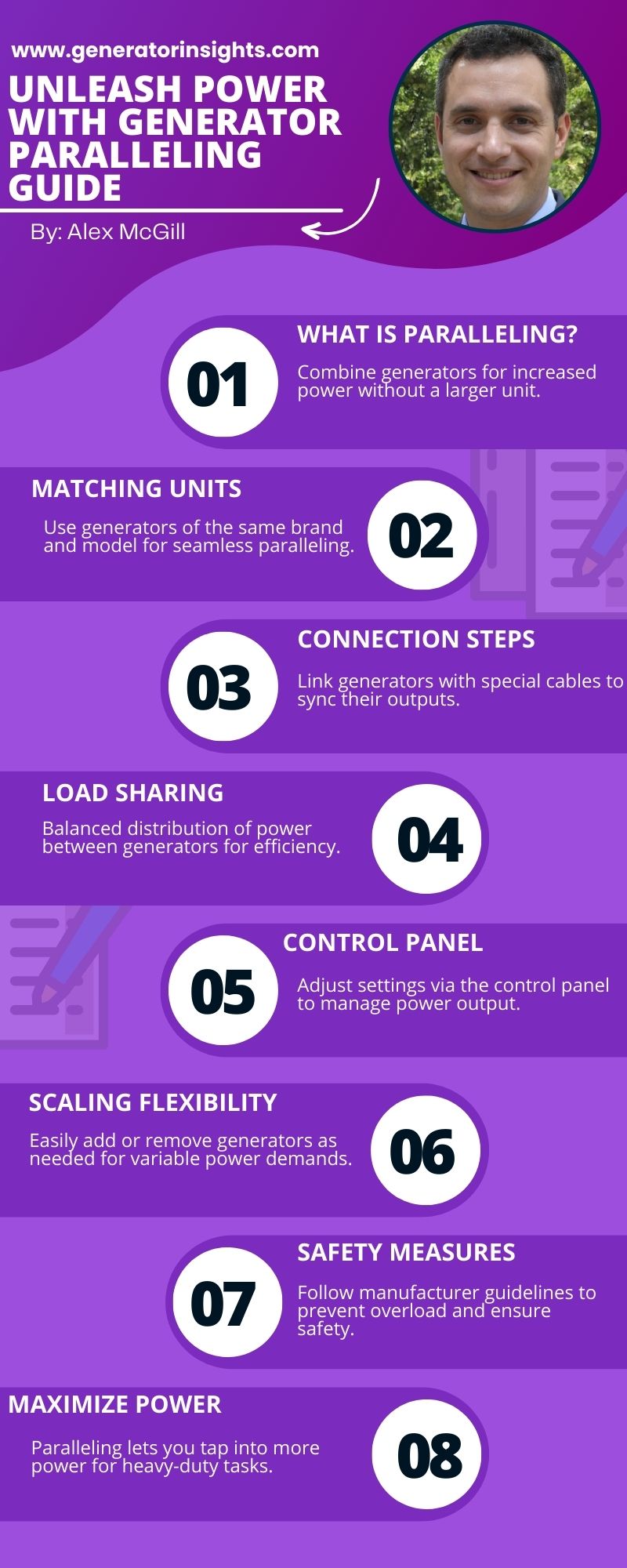

Step-by-Step Generator Paralleling Guide

Generator paralleling is the process of connecting multiple generators to work together in a synchronized manner. This guide will walk you through the essential steps to ensure a seamless paralleling setup.

- Assess Generator Compatibility:

- Confirm that all generators are of the same make and model to ensure compatibility.

- Check if the generators have similar kVA (kilovolt-ampere) ratings for balanced load sharing.

- Verify Electrical Compatibility:

- Ensure that the generators have matching voltage ratings to prevent electrical imbalances.

- Confirm that the generators share the same frequency (Hertz) for synchronization.

- Install Synchronizing Equipment:

- Install automatic synchronizers to manage the synchronization process.

- Connect synchronizing relays to the generators for real-time communication.

- Adjust Governor Settings:

- Set the governor control systems to the same speed and response characteristics.

- Ensure that the governors are capable of maintaining consistent engine speed during load changes.

- Connect Load Sharing Equipment:

- Install load-sharing modules to distribute the load equally among the generators.

- Adjust load-sharing settings to maintain balance during varying power demands.

- Synchronize Voltage Regulators:

- Calibrate voltage regulators to maintain a constant output voltage.

- Ensure that all generators respond uniformly to changes in load conditions.

- Perform Synchronization Test:

- Conduct a synchronization test using the automatic synchronizers.

- Verify that the generators are in sync and sharing the load evenly.

- Monitor Parallel Operation:

- Regularly monitor parameters such as voltage, frequency, and current during parallel operation.

- Implement automatic load shedding mechanisms to prevent overloading.

This step-by-step guide provides a straightforward approach to generator paralleling, ensuring a reliable and balanced power supply.

Why You Need to Parallel Generators?

When it comes to power generation, the use of generators plays a crucial role in meeting our energy needs. However, there’s a growing trend toward employing multiple generators simultaneously, a practice known as parallel generation. Let’s explore why this approach is gaining popularity and the benefits it offers.

- Enhanced Reliability:

- Parallel generators provide a reliable backup in case one generator fails. If a single unit malfunctions, the others can seamlessly take over, ensuring a continuous and uninterrupted power supply.

- Increased Power Output:

- Parallel operation allows for the combined output of multiple generators, resulting in a higher overall power capacity. This is especially beneficial in situations where a higher energy demand needs to be met.

- Efficient Load Sharing:

- When generators operate in parallel, they can share the load more efficiently. This prevents individual units from being overloaded and promotes a balanced distribution of the power demand among the generators.

- Fuel Efficiency:

- Running generators in parallel at partial loads can contribute to improved fuel efficiency. Instead of operating a single generator at low loads, which is often less efficient, multiple generators can collectively handle the load more optimally.

- Scalability:

- Parallel generators offer a scalable solution for varying power requirements. As demand increases, additional generators can be added to the system, providing a flexible and cost-effective way to adapt to changing energy needs.

- Maintenance Flexibility:

- Parallel operation facilitates easier maintenance schedules. When one generator is taken offline for maintenance or repairs, the others can continue to supply power, reducing downtime and ensuring a more consistent energy supply.

How to Choose Generators for Parallel Operation?

Choosing generators for parallel operation is crucial for ensuring a reliable and efficient power supply. When considering multiple generators working together, several factors need careful consideration to optimize their performance. Let’s delve into the key aspects to guide you through this decision-making process.

1. Generator Compatibility

Before anything else, ensure that the generators you’re considering are compatible for parallel operation. This involves checking their technical specifications, such as voltage, frequency, and waveform compatibility. Using generators with mismatched parameters can lead to inefficiencies and potential damage.

2. Synchronization Capability

Synchronization is a critical aspect when running generators in parallel. Generators must operate at the same frequency and phase to avoid power imbalances and potential damage to connected equipment. Invest in generators equipped with advanced synchronization features to facilitate seamless parallel operation.

3. Load Sharing Control

Choose generators with load sharing control capabilities. This feature ensures that the connected load is distributed evenly among the generators. Proper load sharing prevents overloading of individual generators and promotes optimal utilization of the entire system.

4. Voltage Regulation

Stable voltage regulation is essential to maintain a consistent power supply. Generators with precise voltage control mechanisms help in managing fluctuations and ensure that connected devices receive a steady power output.

5. Parallel Switchgear

Invest in a reliable parallel switchgear system that facilitates the seamless connection and disconnection of generators in parallel. The switchgear should provide protection features, such as overcurrent and overvoltage protection, to safeguard the generators and the connected load.

In summary, when choosing generators for parallel operation, prioritize compatibility, synchronization, load-sharing control, voltage regulation, and invest in reliable parallel switchgear systems. This ensures a smooth and reliable power supply while minimizing the risk of equipment damage.

How to Parallel Two Generators?

Parallelizing two generators can significantly enhance power output, making it a practical solution in scenarios where increased electrical capacity is required. Parallel operation involves connecting two generators to work together seamlessly, sharing the load. This guide will walk you through the step-by-step process of parallelizing generators, ensuring a smooth and efficient power supply.

Step 1: Check Generator Compatibility

Before attempting to parallel two generators, it’s crucial to confirm that they are compatible for parallel operation. Check the manufacturer’s specifications and user manuals for both generators. Ensure that they have the same voltage rating, frequency, and are equipped with a parallel operation capability.

Step 2: Prepare the Generators

- Set the Operating Parameters: Adjust the operating parameters on both generators to match each other precisely. This includes synchronizing the voltage, frequency, and any other relevant settings.

- Turn Off Automatic Voltage Regulator (AVR): Disable the AVR on both generators. This ensures that each generator adjusts its voltage based on the load it is carrying, allowing for a balanced distribution of power.

Step 3: Connect the Generators

- Use Parallel Cables: Connect the generators using specialized parallel cables designed for this purpose. These cables facilitate communication between the generators, enabling them to synchronize and share the load evenly.

- Ensure Proper Phasing: Check and ensure that the generators are in phase with each other. This is critical for maintaining a stable and synchronized power supply.

Step 4: Synchronize the Generators

- Start the Generators: Begin by starting one generator and allowing it to stabilize. Then, start the second generator.

- Adjust Frequency and Voltage: Use the built-in controls to adjust the frequency and voltage of the generators until they match. Some generators come equipped with automatic synchronization features, simplifying this process.

Step 5: Load Sharing

- Activate Load Sharing: Once the generators are synchronized, activate the load-sharing function. This allows the generators to distribute the electrical load evenly, preventing one generator from taking on more load than the other.

- Monitor System Parameters: Continuously monitor the system parameters, including voltage, frequency, and load distribution, to ensure that both generators are operating within their specified limits.

By following these steps, you can successfully parallel two generators, providing a reliable and efficient power supply tailored to your specific needs.

Can You Parallel Two Different Brand Inverter Generators?

The short answer is, while it’s technically feasible, it’s generally not recommended. Inverter generator models from different brands may have variations in voltage regulation, frequency stability, and other key parameters. These differences can lead to compatibility issues when attempting to parallel them.

Parallel operation requires synchronized output to prevent damage to connected devices and maintain a stable power supply. When generators of different brands are paralleled, there’s a risk of mismatched electrical characteristics, potentially causing damage to the generators or connected appliances. For seamless and safe parallel operation, it’s advisable to use generators of the same brand and model. This ensures compatibility and harmony in their electrical outputs, preventing any unforeseen issues.

While some users may attempt to parallel different brand generators using aftermarket parallel kits, the risks associated with mismatched electrical characteristics remain a concern. Therefore, for optimal performance and safety, it’s recommended to parallel inverter generators from the same brand and model.

Can You Parallel Two Different Size Inverter Generators?

The short answer is, it’s generally not recommended. Inverter generators are designed to work in parallel with units of the same make and model, ensuring compatibility and optimal performance.

Attempting to parallel generators with different sizes can lead to several issues. First, it can cause an imbalanced load distribution between the two generators, potentially overloading one unit while underutilizing the other. This not only affects the efficiency of the generators but also poses a risk of damage to the equipment. Additionally, different-sized generators may have varying voltage and frequency outputs, further complicating the synchronization process.

Thus, while it might be tempting to mix and match different-sized inverter generators to meet your power needs, it’s crucial to follow the manufacturer’s recommendations. Parallel operation is best suited for generators of the same make and model to ensure compatibility, efficient load distribution, and safe operation.

Tips for Running Generators in Parallel

When running two generators in parallel, efficiency and proper management become crucial. Here are some tips to ensure a smooth operation.

- Synchronize Voltage and Frequency:

- Maintain consistent voltage and frequency between the generators to prevent potential damage to connected devices.

- Match Generator Capacities:

- Use generators with similar power capacities to avoid overloading one while underutilizing the other.

- Parallel Connection Setup:

- Follow the manufacturer’s guidelines for proper parallel connection, ensuring a secure and stable configuration.

- Automatic Voltage Regulators (AVRs):

- Ensure both generators are equipped with effective AVRs to automatically adjust voltage fluctuations, maintaining a stable output.

- Load Sharing Control:

- Implement a reliable load-sharing control system to distribute the load evenly between the generators, preventing imbalance and optimizing performance.

- Synchronization Panel:

- Utilize a synchronization panel to align the generators’ phases precisely, preventing electrical conflicts and ensuring seamless parallel operation.

- Proper Grounding:

- Establish a robust grounding system for both generators to enhance safety and minimize the risk of electrical issues.

- Regular Maintenance:

- Conduct routine maintenance checks on both generators to identify and address any issues promptly, ensuring long-term reliability.

- Emergency Shutdown Procedures:

- Establish clear emergency shutdown procedures, enabling a quick response in case of any abnormalities or malfunctions during parallel operation.

Remember, proper synchronization and load management are key to successfully running two generators in parallel, ensuring a reliable and efficient power supply.

Common Mistakes to Avoid When Running Generators in Parallel

When running two generators in parallel, it’s crucial to be mindful of certain common mistakes that can hinder efficiency and performance. Here are some key points to consider:

| Mistake | Explanation |

|---|---|

| Insufficient Power Supply | Ensure that both generators receive an adequate power supply to avoid performance issues. Inadequate power can lead to equipment damage and system failures. |

| Mismatched Generator Capacities | Use generators with compatible capacities. Mismatched capacities may lead to overloading or underutilization, impacting overall efficiency. |

| Incorrect Synchronization | Proper synchronization is vital to prevent power imbalances and ensure seamless operation. Incorrect synchronization can lead to equipment damage and safety hazards. |

| Neglecting Load Distribution | Distribute the load evenly between the generators to prevent one from overworking while the other remains underutilized. This promotes optimal performance and longevity. |

| Inadequate Maintenance | Regularly conduct maintenance checks on both generators to identify and address issues promptly. Neglecting maintenance can result in unexpected breakdowns. |

By avoiding these common mistakes, you can ensure the smooth and effective operation of two generators running in parallel.

Troubleshooting Common Generator Paralleling Issues

In generator paralleling systems, combining multiple generators is a common practice to enhance power capacity and reliability. However, certain issues may arise, affecting the seamless operation of these parallel systems. Let’s explore some common problems and their troubleshooting solutions.

| Issue | Symptoms | Possible Causes | Troubleshooting Steps |

|---|---|---|---|

| 1. Load Imbalance | Uneven distribution of power among paralleled generators, leading to inefficiencies. | – Faulty load-sharing mechanisms. – Differences in generator set points. | – Verify Load Sharing: Check and recalibrate load-sharing devices. – Adjust Set Points: Ensure that generator set points are consistent. |

| 2. Frequency Drift | Variances in output frequency among generators, impacting system stability. | – Engine speed deviations. – Incorrect governor settings. | – Governor Calibration: Adjust governor settings to maintain consistent engine speed. – Engine Synchronization: Ensure all engines are synchronized for uniform frequency. |

| 3. Voltage Fluctuations | Unstable voltage levels compromising equipment performance. | – Voltage regulator malfunctions. – Poor connection points. | – Regulator Inspection: Check and recalibrate voltage regulators. – Connection Checks: Examine electrical connections for loose or damaged components. |

| 4. Sudden Load Changes | Inconsistent responses to load variations, affecting overall system reliability. | – Slow response time in load-sharing systems. – Inadequate communication between generators. | – Upgrade Load-Sharing Systems: Implement faster load-sharing devices. – Enhance Communication Protocols: Ensure efficient communication between generators. |

| 5. Overloading | Excessive load on one or more generators, risking equipment damage. | – Incorrect load distribution. – Generator capacity miscalculations. | – Load Redistribution: Balance loads evenly among generators. – Capacity Review: Reevaluate generator capacities to prevent overloading. |

Understanding these common issues and their troubleshooting steps is essential for maintaining the reliability and efficiency of paralleled generator systems. Regular inspections and proactive measures can significantly contribute to the smooth operation of such power setups.

Generator Maintenance Tips

- Regular Inspections: Conduct routine checks on the generator’s components, such as the engine, fuel system, and electrical connections. Look for signs of wear, leaks, or corrosion.

- Oil Change: Change the generator’s oil at regular intervals, as specified in the manufacturer’s manual. Fresh oil ensures proper lubrication, preventing friction and reducing the risk of engine damage.

- Fuel System Care: Keep the fuel system clean by using clean and stable fuel. Dirty fuel can lead to clogs and affect the generator’s performance. Additionally, use fuel stabilizers to prevent fuel degradation during periods of inactivity.

- Battery Maintenance: Check the battery regularly for corrosion and charge levels. Clean the terminals to ensure a strong connection. Consider using a battery maintainer during periods of inactivity to prevent discharge.

- Cooling System Inspection: Examine the cooling system, including the radiator and hoses, for any signs of damage or leaks. Ensure there is an adequate amount of coolant, and replace it as needed to prevent overheating.

- Air Filter Replacement: Replace the air filter based on the manufacturer’s recommendations. A clogged filter can reduce airflow, leading to decreased efficiency. Regular replacement helps maintain optimal performance.

- Load Testing: Perform regular load tests to simulate the generator’s performance under actual operating conditions. This ensures that the generator can handle the required load during power outages.

- Keep a Log: Maintain a maintenance log documenting all inspections, repairs, and maintenance activities. This log provides a record of the generator’s history and aids in identifying patterns or potential issues.

- Professional Servicing: Schedule professional servicing at recommended intervals. Certified technicians can identify and address potential problems before they escalate, ensuring the generator’s reliability.

Remember, proactive and regular maintenance is key to ensuring your generator operates efficiently and reliably when needed.

Conclusion

In conclusion, the Generator Paralleling Guide demystifies the complex world of parallel generators, offering a roadmap to enhanced power capabilities and efficiency. Whether for residential or commercial use, the benefits of generator paralleling extend to maximizing capacity, minimizing downtime, and optimizing resource usage.

As you venture into the realm of parallel generators, let this guide be your companion, equipping you with insights to make informed decisions for your power needs. By embracing the art of generator paralleling, you can create a resilient and scalable energy solution that adapts to your requirements, ensuring a continuous and reliable power supply.

References

- Electric generators and motors: An overview

- Analysis of a micro-electric generator for microsystems

- Linear electric actuators and generators

- Electrical generators for large wind turbine: Trends and challenges

Frequently Asked Questions

Can generators of different sizes and brands be paralleled together?

Generators of different sizes and brands can be paralleled together, offering benefits such as increased power output, improved reliability, and flexibility in meeting varying load demands. This allows for efficient utilization of multiple generators.

Is it possible to parallel generators with different fuel types?

Generator compatibility depends on fuel type compatibility. Generators with different fuel types may not be able to be paralleled together, as they require specific fuel systems and components that are designed for their respective fuels.

How does generator paralleling affect the overall power quality?

Generator paralleling can have a significant impact on power stability and voltage regulation. When multiple generators are connected in parallel, careful synchronization is required to maintain a balanced load and prevent fluctuations in voltage and frequency.

What are the common challenges faced when paralleling generators?

Challenges in generator paralleling include synchronizing voltage, frequency, and phase angle. Other issues can arise from differences in load sharing and control systems. Solutions involve implementing advanced monitoring and control technologies to ensure optimal performance and stability.

Are there any limitations or restrictions when it comes to paralleling generators in certain environments or applications?

Limitations of paralleling generators can arise from environmental considerations. Factors such as altitude, temperature, and humidity affect generator performance. Proper cooling and ventilation are crucial to prevent overheating and ensure optimal functioning in different environments or applications.

What are the steps in paralleling the generators?

To parallel generators, it’s crucial to ensure that the voltage from the incoming generator instantly matches the bus bar. Additionally, the frequency and phase of the incoming generator must align with the bus bar voltage, including matching phase sequences.

Does paralleling generators double the wattage?

Paralleling generators involves connecting two generators (usually of the same brand, type, and size) to provide double the wattage. In simpler terms, this process combines their power output.

What are the requirements for connecting generators in parallel?

When connecting generators in parallel, synchronization is key. This entails ensuring proper matching of voltage and frequency, and balancing the load distribution. Each Generator Set’s regulator, handling thermal and excitation regulation, performs this critical function.