In a world that never stops, where power outages are unexpected guests, we all yearn for a reliable companion – enter the portable generator. Picture this: a reliable source of electricity, ready at your command. But, have you ever wondered, in those crucial moments, How long does a portable generator last on a tank of gas? It’s a question that echoes in the minds of those seeking uninterrupted comfort.

As we delve into the heartbeat of power solutions, we’ll not only explore the endurance of these mighty machines but also uncover the secret to prolonged peace of mind. Buckle up; we’re about to navigate the terrain of energy resilience.

Jump to a Specific Section

- 1 Main Points

- 2 Why is Generator Runtime Important?

- 3 How Long Does a Portable Generator Last on a Tank of Gas?

- 4 How Long Does a Standby Generator Run?

- 5 What Factors Impact the Generator Runtime?

- 6 How to Calculate Generator Fuel Consumption?

- 7 Troubleshooting Common Generator Issues

- 8 Maintenance Tips for Portable Generator

- 9 Safety Tips for Portable Generator

- 10 Conclusion

- 11 References

- 12 Frequently Asked Questions

- 12.1 How Much Gas Does a Portable Generator Need?

- 12.2 What Is the Difference Between Running Time and Tank Size?

- 12.3 What Type of Fuel Should I Use for My Generator?

- 12.4 How Often Should I Maintain My Generator?

- 12.5 How Can I Increase the Efficiency of My Generator?

- 12.6 How long will a portable generator run on a tank of gas?

- 12.7 How long will a 20lb propane tank last on a portable generator?

- 12.8 How long can a generator sit with gas?

Main Points

- The factors that affect generator runtime and efficiency include the size and efficiency of the generator, the fuel type used, load factors and their impact on runtime, and usage patterns and environmental conditions.

- Tank size and fuel consumption are important considerations when determining generator runtime. Researching and comparing fuel efficiency ratings, checking manufacturer’s specifications, and selecting a generator with optimal fuel economy can help maximize runtime and potential cost savings over time.

- Load size and wattage play a role in both generator runtime and fuel efficiency. Staying within the manufacturer’s recommendations, estimating required wattage accurately, and accounting for spikes in power usage can help avoid overloading and optimize fuel consumption.

- Proper maintenance and fuel type considerations are essential for generator performance and longevity. Regular servicing, using fuel additives and proper tuning, checking for air leaks and spark plug condition, and maintaining clean fuel and oil levels contribute to better efficiency and fewer maintenance issues.

Why is Generator Runtime Important?

Generator Runtime essentially refers to the cumulative duration for which a generator operates, actively producing electricity. This metric serves as a fundamental indicator of the generator’s utilization and performance over a specific period. A judicious assessment of generator runtime unveils valuable insights into its reliability, maintenance requirements, and overall operational health.

One paramount reason why generator runtime holds paramount importance is its direct correlation with maintenance schedules. Extended operation periods can accelerate wear and tear on essential components, necessitating more frequent maintenance interventions. Striking the right balance in generator runtime is, therefore, imperative to optimize maintenance costs while ensuring the longevity of the equipment.

Moreover, generator runtime plays a pivotal role in fuel consumption and operational costs. By meticulously monitoring and managing the runtime, organizations can enhance fuel efficiency and curtail expenses associated with power generation. This becomes particularly crucial in sectors where energy costs significantly impact the bottom line.

Consider an industrial setting where a backup generator is a critical component for uninterrupted operations. If the generator runtime is excessively prolonged without corresponding load requirements, it not only escalates fuel consumption but also accelerates the need for unscheduled maintenance, potentially leading to operational disruptions.

Thus, comprehending the importance of generator runtime is integral for making informed decisions in power management. Striking the right balance ensures operational efficiency, cost-effectiveness, and the prolonged lifespan of the generator, thereby fostering a reliable and sustainable power supply for diverse applications.

How Long Does a Portable Generator Last on a Tank of Gas?

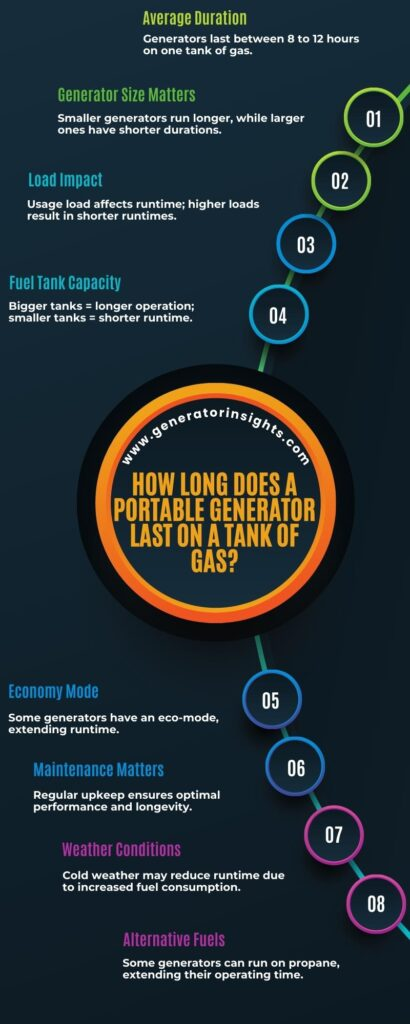

The average continuous runtime for portable generators on a full tank of gas typically ranges from 6 to 18 hours. However, this can vary based on the generator’s size, brand, and specific features. It’s important to consult the manufacturer’s specifications for accurate information tailored to your generator model.

Fuel type plays a role in determining how long a portable generator can operate. Gasoline-powered generators are common and offer convenience, but propane and diesel generators are known for their fuel efficiency and longer runtimes.

Gasoline portable generators can run continuously for about 6-16 hours. On the other hand, propane generators are praised for their cleaner burning and extended shelf life as they can run for about 150-200 hours but it is recommended to run them continuously in intervals of 12-18 hours.

Last but not least the diesel generators can run for as long as 500 hours but it is recommended to run the portable diesel generators continuously for about 24-36 hours.

It is worth mentioning that fuel efficiency is also a crucial aspect that varies among different models and types of generators. Additionally, the capacity of the fuel tank and the load on the generator significantly impact its runtime.

Understanding your portable generator’s fuel consumption and capacity is vital for effective usage, ensuring you have a reliable power source for the required duration. Always refer to the manufacturer’s guidelines and specifications for precise information on your specific generator model.

How Long Does a Standby Generator Run?

When considering the duration of operation for a standby generator, it’s crucial to understand that these units play a pivotal role in providing backup power during outages. On average, a standby generator has the capacity to run for up to 3,000 hours. This runtime estimate is based on powering a medium-sized home with the generator operating intermittently.

However, a key recommendation is not to run a generator continuously for more than 500 hours. Exceeding this threshold could lead to accelerated wear and tear on the generator components, potentially affecting its overall lifespan and performance. Regular maintenance checks become even more critical when approaching or surpassing the 500-hour mark to ensure optimal functionality.

The runtime of a standby generator can be influenced by various factors, such as the generator’s size, the load it’s supporting, and the type of fuel it utilizes. It’s important for users to be mindful of these factors to gauge the expected operational time accurately.

What Factors Impact the Generator Runtime?

Understanding the factors that influence generator runtime is crucial for optimizing performance and ensuring efficient power generation. Several key elements can impact the overall runtime of a generator, influencing its reliability and effectiveness. Let’s delve into these factors in detail.

Fuel Type

The choice of fuel for a generator is a critical factor that strongly influences its overall runtime. Different fuel types have distinct energy characteristics, affecting the efficiency and duration of power generation.

- Diesel Generators:

- Diesel generators are renowned for their extended runtimes.

- The higher energy density of diesel fuel means that a smaller volume of fuel can produce a significant amount of power. This results in longer operational periods without the need for frequent refueling.

- Gas-Powered Generators:

- Gas generators, while efficient, generally have shorter runtimes compared to their diesel counterparts.

- Gasoline and natural gas have lower energy densities than diesel, requiring a larger volume of fuel to generate the same amount of power. As a result, gas generators may need more frequent refueling, impacting their overall runtime.

Load Capacity

The load capacity directly influences how hard the generator has to work. Operating a generator at or near its maximum load capacity means it is being pushed to its limits, and this can have several implications for its runtime.

Effect on Generator Runtime:

- Shorter Runtimes: When a generator operates at or close to its maximum load capacity for an extended period, it tends to experience increased stress and heat. This can lead to accelerated wear and tear on components, ultimately resulting in shorter runtimes before maintenance or repairs are required.

- Lower Efficiency: Running a generator at its maximum load might seem like an efficient use of its capacity, but it often leads to decreased overall efficiency. Generators are designed to operate most efficiently within a certain load range. Running below the maximum capacity allows the generator to work more comfortably and efficiently.

- Maintenance Frequency: Generators operating at high loads may require more frequent maintenance. This is because the increased stress on components can lead to faster deterioration, necessitating regular check-ups and servicing to ensure continued reliable performance.

Optimizing Load for Longer Runtimes:

To maximize generator runtime and efficiency:

- Match Load to Generator Capacity: Select a generator with a capacity that comfortably covers the expected load, preventing the need to constantly operate at maximum capacity.

- Load Balancing: Distribute the electrical load evenly across multiple generators if applicable, avoiding overloading any single unit.

- Efficient Load Management: Utilize load management systems to adjust and distribute loads dynamically, optimizing the generator’s performance.

By understanding and managing the load capacity effectively, you can significantly enhance the overall longevity and performance of your generator, ensuring it operates reliably over an extended period.

Environmental Conditions

The environment in which a generator operates plays a crucial role in determining its performance and overall efficiency. Here’s a closer look at how specific environmental factors can influence a generator’s runtime:

- Temperature:

- Extreme temperatures, whether excessively high or low, can impact the functioning of a generator.

- High temperatures can lead to overheating, affecting the engine and potentially shortening the generator’s runtime.

- On the other hand, extremely cold temperatures can affect the viscosity of lubricants and make it challenging for the generator to start.

- Humidity:

- Humidity levels in the air can affect the combustion process within the generator’s engine.

- High humidity may lead to moisture entering the engine, potentially causing corrosion and reducing efficiency.

- In contrast, low humidity can contribute to increased static electricity, which may impact the generator’s electronic components.

- Altitude:

- Altitude is a critical factor, especially for generators used at higher elevations.

- As altitude increases, the air density decreases, affecting the air-fuel mixture in the engine.

- Generators operating at higher altitudes may experience a reduction in power output and efficiency, impacting overall runtime.

Addressing these environmental considerations is essential for ensuring that the generator operates optimally. This may involve implementing additional cooling systems for extreme temperatures, controlling humidity levels in the generator room, or adjusting the generator’s settings for different altitudes. By understanding and mitigating the impact of environmental conditions, you can enhance the reliability and longevity of your generator, ultimately maximizing its runtime in varying operational environments.

Generator Size and Efficiency

When we talk about the physical size of a generator, we’re referring to its power output capacity, often measured in kilowatts (kW) or megawatts (MW). The size of a generator determines how much electrical power it can produce. Larger generators typically have a higher power output capacity compared to smaller ones.

Now, let’s delve into the concept of efficiency. Efficiency in this context refers to how well the generator converts the energy from its fuel source into electrical power. A more efficient generator can produce more power with the same amount of fuel, resulting in a longer runtime for a given fuel supply.

Here’s the breakdown:

- Larger Size, Greater Output:

- Larger generators are designed to handle higher electrical loads.

- Their increased size allows them to produce more power, making them suitable for applications with substantial energy requirements.

- Matching Load with Generator Size:

- It’s crucial to match the generator size with the actual load it needs to support.

- If a generator is too small for the required load, it may run at maximum capacity, leading to inefficiency and a shorter runtime. On the other hand, if a generator is significantly larger than the load, it may operate below its optimal efficiency range.

- Efficiency and Fuel Economy:

- More efficient generators extract a higher percentage of energy from the fuel they consume.

- This increased efficiency translates into better fuel economy, allowing the generator to run for a longer duration on the same amount of fuel.

How to Calculate Generator Fuel Consumption?

Understanding generator fuel consumption is crucial for efficient power management. Calculating this metric allows you to estimate operational costs and plan fuel reserves effectively.

- Determine Generator Rating:

- Identify the generator’s rated power in kilowatts (kW). This information is usually available in the product specifications.

- Find Fuel Consumption Rate:

- Look for the specific fuel consumption (SFC) value in the generator’s documentation. SFC is the amount of fuel needed to generate one unit of power for an hour.

- Calculate Fuel Consumption:

- Use the formula: Fuel Consumption (in liters/hour) = Generator Rating (kW) x SFC (liters/kW-hour).

- For example, if a generator is rated at 50 kW and has an SFC of 0.2 liters/kW-hour, the fuel consumption would be 50 kW x 0.2 liters/kW-hour = 10 liters/hour.

- Consider Load Factor:

- Adjust the calculated fuel consumption based on the load factor. If the generator operates at less than maximum capacity, multiply the fuel consumption by the load factor (expressed as a decimal).

- Account for Efficiency Loss:

- Factor in efficiency losses during power generation. Reduce the calculated fuel consumption by the generator’s efficiency percentage.

Troubleshooting Common Generator Issues

| Issue | Symptoms | Possible Causes | Troubleshooting Steps |

|---|---|---|---|

| Generator Won’t Start | – No response when attempting to start. | – Empty fuel tank. – Faulty ignition system. | 1. Check and refill the fuel tank. 2. Inspect the ignition system for any issues. |

| Generator Shuts Down Abruptly | – Sudden shutdowns during operation. | – Overloaded generator. – Low oil levels. | 1. Reduce the load on the generator if overloaded. 2. Ensure adequate oil levels; top up if necessary. |

| Unstable Voltage Output | – Fluctuating power supply from the generator. | – Voltage regulator issues. – Faulty alternator. | 1. Inspect the voltage regulator for malfunctions. 2. Check the condition of the alternator and replace if necessary. |

| Excessive Vibration or Noise | – Unusual vibrations or excessive noise. | – Loose components. – Faulty engine mounts. | 1. Tighten any loose components. 2. Inspect and replace faulty engine mounts if necessary. |

| Smoke or Unusual Odors | – Smoke emissions or strange odors. | – Oil or fuel leaks. – Burning components. | 1. Identify and repair oil or fuel leaks. 2. Investigate and replace any burning components. |

| Electric Shock or Sparks | – Electric shock sensations or visible sparks. | – Faulty wiring. – Damaged outlets. | 1. Examine and replace any faulty wiring. 2. Repair or replace damaged outlets to prevent electric shock hazards. |

| Difficulties with Engine Starting | – Slow cranking or difficulty turning over. | – Weak battery. – Faulty starter motor. | 1. Test and, if necessary, replace the battery. 2. Inspect the starter motor for issues and repair or replace as needed. |

| Generator Runs but No Power Output | – Engine running normally but no electricity. | – Faulty generator head. – Damaged wiring. | 1. Check the generator head for faults and replace if necessary. 2. Inspect and replace any damaged wiring in the electrical system. |

| Fuel Leaks | – Visible fuel leakage around the generator. | – Damaged fuel lines. – Loose fuel connections. | 1. Identify and replace damaged fuel lines. 2. Tighten any loose fuel connections to prevent leaks. |

Maintenance Tips for Portable Generator

Portable generators are indispensable during power outages, ensuring a seamless energy supply. Proper maintenance is crucial to enhance their longevity and performance. Here are essential tips to keep your portable generator running smoothly:

- Regular Inspections: Conduct routine checks for any signs of wear, leaks, or loose parts to prevent potential issues.

- Oil Change: Maintain optimal engine function by changing the oil as recommended by the manufacturer; typically, this is every 100-200 hours of operation.

- Air Filter Care: Clean or replace the air filter to promote efficient combustion and safeguard the engine from dirt and debris.

- Fuel Stability: Use stabilized fuel to prevent clogs and varnish buildup in the carburetor, especially during prolonged storage periods.

- Battery Check: Ensure the generator’s battery is charged and corrosion-free to guarantee a reliable start when needed.

- Run the Generator Regularly: Exercise the generator every few months with a light load to keep the engine and alternator in good working order.

- Storage Considerations: Store the generator in a dry, well-ventilated space, protecting it from the elements and potential damage.

By following these maintenance tips, you’ll maximize the efficiency and lifespan of your portable generator, ensuring it’s ready to power up when you need it most.

Safety Tips for Portable Generator

When using a portable generator, ensuring safety is paramount. Follow these safety tips to make the most of your generator while minimizing risks.

- Proper Ventilation:

- Ensure adequate ventilation to prevent carbon monoxide buildup.

- Place the generator outdoors in an open area to dissipate exhaust gases.

- Keep Distance:

- Maintain a minimum of 20 feet distance between the generator and your home.

- This reduces the risk of carbon monoxide entering living spaces.

- Grounding:

- Ground the generator properly to prevent electrical shocks.

- Use a grounding rod and connect it securely to the generator frame.

- Fuel Safety:

- Store fuel in approved containers away from the generator.

- Turn off the generator and let it cool before refueling to avoid accidents.

- Regular Inspections:

- Inspect the generator regularly for leaks, loose parts, or any potential hazards.

- Address issues promptly to maintain safe operation.

- Extension Cord Usage:

- Use heavy-duty extension cords designed for outdoor use.

- Inspect cords for damage before connecting them to the generator.

- Weather Precautions:

- Operate the generator in dry conditions to avoid electrical hazards.

- If it starts raining, cover the generator with a canopy to shield it from water.

- Emergency Shutdown:

- Know the location of the emergency shut-off switch and how to use it.

- Practice shutting down the generator quickly in case of an emergency.

- Education and Training:

- Educate family members on generator safety protocols.

- Conduct a family drill to ensure everyone knows what to do during a power outage.

- Respect Load Capacity:

- Do not overload the generator beyond its capacity.

- Calculate the total wattage of connected devices to stay within safe limits.

Remember, prioritizing safety when using a portable generator is crucial for a smooth and secure power supply.

Conclusion

In conclusion, knowing How Long Does a Portable Generator Last on a Tank of Gas empowers you to make informed decisions during power outages or outdoor adventures. By considering generator specifications and adopting smart usage habits, you can extend its runtime and enjoy uninterrupted electricity supply. Regular maintenance and judicious fuel management further enhance the longevity of your generator.

Let this guide be your go-to resource, providing you with the knowledge and confidence to get the most out of your portable power source. With these insights, you can confidently navigate any situation where reliable electricity is a must.

References

- Linear electric actuators and generators

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

Frequently Asked Questions

How Much Gas Does a Portable Generator Need?

A portable generator typically runs on gasoline, but may also be powered by alternative fuel sources such as diesel or natural gas. Depending on the size of the generator, a tank may need to be filled with anywhere between 1 and 25 gallons of fuel. Fuel storage options should be considered when purchasing a generator, as proper storage is important for optimal performance.

What Is the Difference Between Running Time and Tank Size?

The difference between running time and tank size depends on the fuel type and power output. For example, a generator with a large tank size may have fewer hours of running time than one with a smaller tank size but higher power output. Understanding these factors helps users select the best generator for their needs.

What Type of Fuel Should I Use for My Generator?

When selecting a fuel for your generator, it is important to consider the type of fuel available and its efficiency. Common options include gasoline, diesel, propane and natural gas. Each has advantages and disadvantages in terms of cost, availability, power output and emissions. Researching these differences can help you make a more informed decision.

How Often Should I Maintain My Generator?

To ensure optimal performance and longevity, one should perform preventative maintenance on their generator regularly. Fuel additives can help extend the life of your generator; a little effort now can save time and money in the long run. Let’s take ownership of our generators to create a sense of belonging and pride.

How Can I Increase the Efficiency of My Generator?

Maximizing generator efficiency requires proper storage of fuel, as well as the use of fuel additives. Storing fuel in a cool and dry place prevents evaporation and helps to preserve the fuel’s combustible properties. Additionally, using additives that contain lubricants can reduce wear and tear on engine parts. Taking these steps will help ensure your generator runs efficiently.

How long will a portable generator run on a tank of gas?

A portable generator’s runtime on a full tank varies. Gasoline generators typically run for 6 to 16 hours, diesel generators for 24 to 36 hours, and propane generators for about 12-18 hours, depending on the tank size. The generator’s fuel tank size also influences how long it runs.

How long will a 20lb propane tank last on a portable generator?

A standard 20 lbs (4.6 gallons) propane tank provides approximately 5 hours of runtime for a portable generator. However, the actual duration depends on the generator’s wattage demand.

How long can a generator sit with gas?

When stored in a cool, dry place with a proper fuel stabilizer, gasoline in a generator’s tank can last up to a year. However, to prevent carburetor clogging, it’s crucial to either use or drain the gasoline within two weeks of inactivity.