Embarking on the journey of setting up an inverter generator is like unlocking a world of power convenience at your fingertips. Picture this: a portable powerhouse ready to light up your adventures or stand by your side during unexpected outages.

In this guide, we’ll navigate the realm of How to Set up Inverter Generators, demystifying the process for you. Whether you’re a weekend warrior craving electricity in the great outdoors or someone preparing for the unexpected, our people-centric approach ensures you won’t just understand the setup; you’ll feel empowered by it. Let’s dive into a seamless fusion of knowledge and ease, making your generator setup an effortless triumph.

Key Takeaways

- Regularly check and maintain oil levels to ensure smooth operation and prevent damage or malfunctions.

- Follow the manufacturer’s guidelines for oil changes and maintenance to extend the generator’s lifespan.

- Properly set up and engage the choke mechanism for a smooth start and efficient operation.

- Monitor power usage of connected appliances to avoid overloading the generator and ensure devices remain within its capacity.

What is an Inverter Generator and How Does It Work?

An inverter generator is a cutting-edge power solution that stands apart from traditional generators. Unlike its counterparts, an inverter generator employs advanced electronic circuitry to convert AC power to DC and then back to a stable AC output. This process ensures a consistent and clean flow of electricity, making it especially suitable for powering sensitive electronic devices.

Here’s how an inverter generator works:

- Voltage Control Mechanism:

- Inverter generators employ advanced electronic components to control voltage fluctuations during the power generation process.

- The generator initially produces AC (Alternating Current) power.

- Transformation to DC Power:

- The AC power generated is then directed through an inverter module, where it undergoes a transformation into DC (Direct Current) power.

- Inversion Back to AC:

- The crucial step involves inverting the DC power back to AC, but with a significant difference.

- Unlike conventional generators, the inverter generator maintains a finely controlled voltage during this inversion process.

- Precision in Voltage Control:

- The inverter technology allows for precise adjustments to the voltage output, ensuring a stable and consistent flow of electricity.

- This level of precision is a stark contrast to traditional generators that may exhibit voltage fluctuations.

- Elimination of Voltage Fluctuations:

- The finely controlled voltage eliminates the fluctuations typically associated with conventional generators.

- This characteristic makes inverter generators particularly suitable for powering sensitive electronic devices, as it minimizes the risk of voltage spikes or drops.

- Reliability and Safety:

- The elimination of voltage fluctuations contributes to the overall reliability of inverter generators.

- The finely tuned voltage control enhances the safety of connected devices, reducing the likelihood of damage due to irregular power supply.

In summary, the inverter generator’s operation involves a sophisticated process of controlling voltage fluctuations, transforming AC to DC, and then finely tuning the inverted power back to AC. This precision ensures a reliable and safe power source with minimal voltage variations, making it an ideal choice for various applications.

What are the Basic Parts of an Inverter Generator?

Inverter generators play a crucial role in providing reliable and stable power, especially in remote locations or during power outages. Understanding the basic components of an inverter generator is essential for users seeking efficient and portable power solutions.

- Engine:

- The engine is the heart of an inverter generator, converting fuel into mechanical energy.

- A smaller, more fuel-efficient engine is a hallmark of inverter generators, ensuring optimal performance.

- Alternator:

- The alternator transforms mechanical energy from the engine into electrical energy.

- In inverter generators, advanced alternators produce clean and stable power, vital for sensitive electronics.

- Inverter Module:

- The inverter module is a key component responsible for converting raw electrical power into a stable AC output.

- This technology allows for a consistent power supply, crucial for electronic devices and appliances.

- Voltage Regulator:

- A built-in voltage regulator maintains a steady voltage output, preventing fluctuations that can damage devices.

- This feature enhances the reliability and safety of the power supply.

- Fuel Tank:

- The fuel tank stores the necessary fuel, typically gasoline or propane, to power the generator.

- Inverter generators are known for their fuel efficiency, providing extended run times on a single tank.

- Control Panel:

- The control panel offers user-friendly access to various functions such as starting, stopping, and monitoring.

- It may include features like fuel gauge, output indicators, and power outlets.

- Muffler:

- The muffler reduces noise produced by the generator, making inverter generators quieter compared to traditional models.

- This feature is valuable for both user comfort and environmental considerations.

- Casing and Frame:

- The generator’s casing and frame provide durability and protection for internal components.

- Sturdy construction ensures the generator can withstand the rigors of transportation and outdoor use.

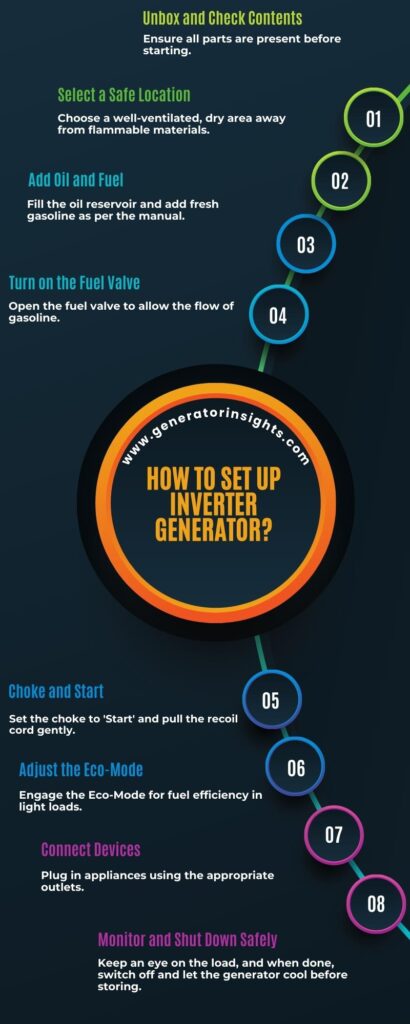

How to Set up Inverter Generator?

Setting up your inverter generator correctly is crucial for efficient and safe operation. Follow these steps to ensure a smooth setup.

- Location:

- Place the generator on a flat, stable surface to prevent accidents and ensure proper ventilation.

- Keep it away from flammable materials, and maintain a minimum clearance as specified in the user manual.

- Fuel:

- Use fresh, clean gasoline with the recommended octane rating mentioned in the manual.

- Avoid ethanol blends exceeding the recommended percentage, as they can damage the generator over time.

- Oil Check:

- Before starting, check the oil level using the dipstick provided.

- Add or replace oil as needed, adhering to the manufacturer’s recommendations.

- Fuel Valve:

- Locate the fuel valve and turn it to the “ON” position.

- Ensure a proper fuel flow for the generator to function correctly.

- Choke:

- Set the choke lever to the “CLOSED” position when starting a cold generator.

- Move it to the “OPEN” position once the engine warms up.

- Pull Cord or Electric Start:

- If equipped with a pull cord, give it a firm but smooth pull to start the engine.

- For electric start models, follow the manufacturer’s instructions for safe and effective starting.

- Eco-Mode:

- Activate the Eco-Mode if your generator has this feature to optimize fuel efficiency during lighter loads.

- This helps reduce noise and fuel consumption.

- Voltage Selector:

- Adjust the voltage selector to match the requirements of your appliances or devices.

- Most generators have both 120V and 240V options.

- Parallel Operation (if applicable):

- If you have multiple generators for higher power output, use the provided parallel operation kit according to the instructions.

- Monitor and Maintenance:

- Periodically check the generator during operation and attend to any issues promptly.

- Follow the recommended maintenance schedule for oil changes, air filter checks, and other routine tasks.

- Shutdown:

- When finished, turn off the generator’s fuel valve and let it run until it stops to use up the remaining fuel in the carburetor.

- Store the generator in a cool, dry place following the manufacturer’s guidelines.

By following these steps, you’ll ensure a safe and efficient setup for your inverter generator, promoting its longevity and reliable performance.

Now let’s discuss these steps in detail.

1. Location

Placing your inverter generator in the right location is crucial for its safety and efficiency. Begin by selecting a flat and stable surface to prevent accidents and ensure the generator’s stability during operation. This step is essential to avoid any potential tipping or instability issues.

Furthermore, it’s vital to provide proper ventilation for the generator. Adequate airflow helps dissipate heat and ensures the generator operates at an optimal temperature. Always adhere to the manufacturer’s guidelines regarding clearance and ventilation to prevent overheating and potential damage to the equipment.

Remember to keep the generator away from any flammable materials. This includes items like paper, leaves, or other substances that could pose a fire hazard. By maintaining a safe distance from potential sources of ignition, you reduce the risk of accidents and enhance the overall safety of the generator setup.

2. Fuel

The type and quality of fuel used in your inverter generator significantly impact its performance and lifespan. Begin by selecting fresh, clean gasoline with the recommended octane rating specified in the user manual. Using the correct fuel ensures proper combustion and prevents engine damage.

It’s crucial to be mindful of the ethanol content in the gasoline. Avoid using fuel with ethanol blends exceeding the recommended percentage, as higher ethanol concentrations can lead to corrosion and damage to the generator’s fuel system over time. Always refer to the manufacturer’s guidelines to determine the maximum acceptable ethanol content for your specific generator model.

3. Oil Check

Regularly checking the oil level in your inverter generator is a fundamental maintenance step that directly impacts its performance and longevity. The dipstick provided is your tool for monitoring the oil level. Before starting the generator, ensure the oil level falls within the recommended range, as indicated in the user manual.

In case the oil level is insufficient, promptly add the recommended type and amount of oil. Regular oil checks and changes, following the manufacturer’s guidelines, are critical for preventing engine damage and maintaining optimal lubrication during operation.

4. Fuel Valve

The fuel valve plays a pivotal role in controlling the fuel flow to the generator’s engine. Locate the fuel valve and ensure it is set to the “ON” position before starting the generator. This step allows a consistent and adequate supply of fuel for proper engine function.

In the event you need to transport or store the generator, turning the fuel valve to the “OFF” position is essential. This prevents fuel from reaching the carburetor and reduces the risk of leaks or potential hazards. Familiarize yourself with the fuel valve’s location and operation, as it is a key component in the overall setup and safe operation of your inverter generator.

5. Choke

The choke is a crucial component when starting a cold inverter generator. The choke lever typically has two positions: “CLOSED” and “OPEN.” When starting the generator from cold, set the choke lever to the “CLOSED” position. This action restricts airflow, enriching the air-fuel mixture for easier ignition.

Once the engine warms up, move the choke lever to the “OPEN” position. This adjustment allows for normal airflow, optimizing the air-fuel ratio during regular operation. Properly managing the choke ensures a smooth start and transition to running conditions, contributing to the generator’s overall efficiency.

6. Pull Cord or Electric Start

Depending on your inverter generator model, you may have either a pull cord or an electric start mechanism. If your generator features a pull cord, give it a firm but smooth pull to start the engine. Be cautious not to yank or jerk the cord, as this can damage the starter mechanism.

For generators equipped with an electric start, follow the manufacturer’s instructions for a safe and effective start. This often involves turning a key or pressing a button to engage the starter motor. Ensure the generator is on a stable surface and that the battery, if applicable, is adequately charged for reliable electric starts.

Whether using a pull cord or electric start, following the recommended starting procedures contributes to the longevity and reliable performance of your inverter generator.

7. Eco-Mode

Many inverter generators come equipped with an Eco-Mode feature designed to optimize fuel efficiency during lighter loads. Activating Eco-Mode adjusts the engine speed based on the power demand, reducing fuel consumption and minimizing noise levels.

By engaging Eco-Mode, the generator runs at lower RPM (revolutions per minute) when the power demand is lower, such as during the operation of smaller appliances. This not only conserves fuel but also contributes to a quieter operation, making it an environmentally and user-friendly choice. Consider activating Eco-Mode when running the generator at partial capacity for extended periods.

8. Voltage Selector

The voltage selector on your inverter generator allows you to tailor the output voltage to match the requirements of your appliances or devices. Most generators offer both 120V and 240V options. Ensure the selector is set to the appropriate voltage before connecting any equipment.

Different appliances may have specific voltage requirements, and selecting the correct voltage setting prevents potential damage to your devices. Always refer to the user manual for guidance on the proper voltage selection based on your power needs. This simple adjustment ensures a safe and compatible power supply for your connected appliances and equipment.

9. Parallel Operation (if applicable)

If you require more power than a single inverter generator can provide, some models offer the option for parallel operation. This involves connecting two generators using a parallel operation kit, typically provided by the manufacturer. Follow these steps:

- Connect the parallel cables to the designated ports on each generator.

- Start both generators and allow them to stabilize.

- Once stable, connect the parallel cables to the parallel operation kit.

- This enables the generators to work together, combining their power output.

Parallel operation increases the overall wattage available, providing flexibility for higher-demand situations. Always refer to the generator’s manual for specific instructions on parallel operation and use only compatible generators for this setup.

10. Monitor and Maintenance

Regular monitoring and maintenance are essential for the longevity and optimal performance of your inverter generator. Follow these steps:

- Periodically check the generator during operation for any unusual sounds, vibrations, or signs of wear.

- Adhere to the manufacturer’s recommended maintenance schedule, including oil changes, air filter checks, and spark plug inspections.

- Address any issues promptly to prevent further damage.

Consistent monitoring and maintenance not only extend the lifespan of your generator but also contribute to reliable and efficient operation when you need it most. Keeping your generator in good condition ensures it’s ready to meet your power needs whenever required.

11. Shutdown

Properly shutting down your inverter generator is as important as starting it correctly. Follow these steps to ensure a safe and effective shutdown:

- Turn the fuel valve to the “OFF” position. This prevents the flow of fuel to the carburetor, allowing the generator to use up the remaining fuel and reducing the risk of leaks during storage.

- Let the generator run until it comes to a complete stop. This helps burn off any residual fuel in the carburetor, preventing potential starting issues in the future.

Additionally, follow any specific shutdown procedures outlined in the user manual. Proper shutdown not only ensures the safety of the generator but also contributes to its longevity. Once the generator has come to a stop, store it in a cool, dry place, following the manufacturer’s guidelines for proper storage.

How to Connect Appliances with Your Inverter Generator?

When it comes to powering your appliances with an inverter generator, choosing the right wiring method is crucial. Below, we’ll explore various options such as extension cords, transfer switches, and dedicated generator cords, highlighting their features and benefits.

| Wiring Method | Description | Example Use Case |

|---|---|---|

| Extension Cords | Simple and cost-effective, extension cords are suitable for connecting individual appliances to your inverter generator. Ensure the cord’s gauge can handle the appliance’s power requirements. | Powering a refrigerator or charging electronic devices. |

| Transfer Switch | Offers a safe and convenient solution for connecting your generator to your home’s electrical system. Allows you to select specific circuits to power during an outage. | Providing backup power to essential home circuits. |

| Generator Cords | Tailored cords designed for direct connection between the generator and appliances. Typically more robust and weather-resistant than standard extension cords. | Running power tools at a construction site. |

Some of the key considerations are:

- Safety: Always prioritize safety by using the appropriate wiring method for the specific application.

- Capacity: Check the power requirements of your appliances and ensure the wiring method can handle the total load.

- Compatibility: Ensure compatibility between the generator and the chosen wiring method.

Remember, understanding your power needs and selecting the right wiring method will optimize the performance and reliability of your inverter generator.

How to Add Inverter to a Generator?

Adding an inverter to a generator is a practical solution to obtain a stable power source for sensitive electronic devices. An inverter converts the generator’s raw power into a cleaner, more consistent electrical output, crucial for powering gadgets like laptops, smartphones, and other sensitive equipment.

- Select an Inverter:

- Choose an inverter that matches the wattage capacity of your generator. Ensure it’s a pure sine wave inverter for optimal performance with electronic devices.

- Gather Tools and Materials:

- Collect tools such as screwdrivers, pliers, wire strippers, and materials like appropriately sized cables and connectors.

- Turn Off the Generator:

- Prior to any installation, make sure the generator is turned off to ensure safety during the process.

- Locate the Generator’s Electrical Panel:

- Identify the generator’s electrical panel where the power is generated. This is usually found near the engine.

- Disconnect the Load:

- Unplug any devices connected to the generator and disconnect the load from the generator’s outlets.

- Access the Generator’s Power Output:

- Open the generator’s panel to expose the power output terminals. Usually, there will be terminals labeled as “L1,” “L2,” and “Neutral.”

- Connect the Inverter:

- Attach the positive (red) cable from the inverter to the “L1” terminal and the negative (black) cable to the “Neutral” terminal.

- Ground Connection:

- Connect the inverter’s grounding wire to the generator’s grounding point. This is typically a green screw on the generator.

- Secure Connections:

- Ensure all connections are tightened securely to prevent any loose wiring issues.

- Route Cables Safely:

- Route the inverter cables away from moving parts and hot surfaces to avoid damage.

- Turn On the Generator:

- Start the generator and check the inverter for proper operation. The inverter should produce a stable power output.

- Connect Devices:

- Reconnect your electronic devices to the inverter’s outlets, which now provide a cleaner and more stable power supply.

Troubleshooting Common Inverter Generator Issues

Inverter generators are essential for reliable power in various settings. However, users may encounter issues that hinder their performance. Understanding and troubleshooting these common problems is crucial for maintaining optimal generator functionality.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| 1. Low Oil Level | Generator shutting down unexpectedly, abnormal engine noise. | Ensure that the oil level is within the recommended range. If low, add the appropriate oil type. Regularly check and change the oil according to the manufacturer’s guidelines. |

| 2. Spark Plug Issues | Difficulty starting, irregular engine operation. | Examine the spark plug for fouling or damage. Clean or replace it if necessary. Ensure the spark plug gap adheres to the manufacturer’s specifications. Regularly inspect and replace spark plugs based on usage and maintenance guidelines. |

| 3. Fuel System Problems | Poor engine performance, starting issues. | Confirm the fuel level and quality. Clean or replace the fuel filter regularly. Inspect the fuel lines for blockages. Ensure the fuel shut-off valve is open. Use fresh, stabilized fuel. Periodically clean the carburetor to prevent varnish buildup. |

| 4. Overloading | Generator shutting down during use, possible damage to appliances. | Check the generator’s wattage capacity and the combined wattage of connected devices. Avoid overloading by redistributing the load or disconnecting non-essential devices. Refer to the generator’s manual for the recommended load limits. |

| 5. Air Filter Clogs | Reduced power output, engine stalling. | Inspect and clean or replace the air filter regularly. A clogged filter can restrict airflow, affecting engine performance. Ensure proper seating of the air filter, and use the recommended filter type. |

| 6. Battery Issues | Electric start not working, insufficient power. | Check the battery voltage using a multimeter. Charge or replace the battery if voltage is low. Inspect and clean battery terminals. Ensure proper storage practices, such as charging the battery before extended periods of inactivity. |

| 7. Inverter Failure | Fluctuating power output, electrical anomalies. | Consult the manufacturer’s guide for inverter troubleshooting. Perform diagnostics using a multimeter. In case of malfunctions, seek professional repair services. Regularly inspect and maintain the inverter components as per the manufacturer’s guidelines. |

| 8. Engine Overheating | Generator shutting down due to overheating. | Check for obstructions around the engine and cooling system. Ensure proper ventilation. Monitor the ambient temperature and avoid running the generator in excessively hot conditions. Regularly clean the cooling fins and maintain proper oil levels. |

By addressing these common issues methodically, users can enhance the longevity and performance of their inverter generators. Regular maintenance and adherence to manufacturer guidelines play a crucial role in ensuring consistent power generation.

How to Properly Store Your Inverter Generator?

Properly storing your inverter generator is crucial for maintaining its longevity and ensuring it’s ready to power up when you need it. A well-maintained generator is more reliable and efficient, so let’s delve into the key steps to store your inverter generator effectively.

- Clean the Generator:

- Remove debris and dust from the generator’s exterior using a soft brush.

- Wipe the surface with a damp cloth to prevent any dirt from settling during storage.

- Check and Change Oil:

- Verify the oil level and change it if needed.

- Fresh oil prevents corrosion and ensures smooth operation upon startup.

- Fuel System Considerations:

- Add a fuel stabilizer to the tank to prevent the formation of varnish and gum.

- Run the generator for a few minutes to allow the stabilizer to circulate through the fuel system.

- Battery Maintenance:

- For generators with electric starters, ensure the battery is fully charged.

- Consider removing the battery for long-term storage and keep it in a cool, dry place.

- Store in a Dry Location:

- Choose a cool, dry location for storage to prevent moisture-related issues.

- Use a breathable cover to protect the generator from dust while allowing proper ventilation.

- Ventilation:

- Ensure the storage area has proper ventilation to prevent the buildup of fumes.

- Avoid storing the generator in enclosed spaces to reduce the risk of carbon monoxide accumulation.

- Regular Maintenance Schedule:

- Establish a regular maintenance schedule even during periods of inactivity.

- Periodically start the generator and let it run for a short duration to keep internal components lubricated.

- Protect from Pests:

- Place mothballs or rodent repellent around the generator to deter pests.

- Inspect the generator periodically for any signs of pest activity.

- Secure from Theft:

- Consider securing the generator with a chain or lock to prevent theft.

- Store it in a location that is not easily accessible to unauthorized individuals.

- Documentation:

- Keep all user manuals and documentation in a safe place for reference.

- Note down the last maintenance date and any specific storage instructions provided by the manufacturer.

By following these steps, you’ll ensure that your inverter generator remains in optimal condition, ready to provide reliable power whenever you need it.

Inverter Generator Maintenance Tips

Ensure optimal performance and longevity of your inverter generator with these essential maintenance tips.

- Scheduled Oil Changes:

- Regularly change the oil as recommended by the manufacturer to maintain proper lubrication and extend the generator’s lifespan.

- Air Filter Inspection:

- Check the air filter routinely, cleaning or replacing it when needed, to prevent engine damage caused by dirt and debris.

- Spark Plug Care:

- Inspect and clean or replace the spark plug regularly to ensure efficient fuel combustion and prevent starting issues.

- Fuel System Maintenance:

- Stabilize the fuel when storing the generator for prolonged periods to prevent varnish buildup in the carburetor and fuel system.

- Battery Check:

- If your generator has a battery, check it for corrosion and maintain a full charge to ensure reliable starts during operation.

- Exhaust System Examination:

- Inspect the exhaust system for any leaks or blockages to maintain optimal engine performance and ensure safe operation.

- Cooling System Inspection:

- Check the cooling system, ensuring the radiator and cooling fins are clean to prevent overheating issues during prolonged use.

- Tighten Loose Parts:

- Regularly inspect and tighten loose nuts, bolts, and screws to prevent vibration-related damage and ensure overall stability.

- Run the Generator Regularly:

- Even if not in use, run the generator periodically to prevent fuel system issues and keep internal components lubricated.

- Store Properly:

- When storing the generator, keep it in a cool, dry place to prevent rust and corrosion, and use a cover to shield it from the elements.

Remember, a well-maintained inverter generator not only ensures reliable power but also extends its lifespan, saving you from costly repairs.

Inverter Generator Safety Tips

When it comes to operating inverter generators, prioritizing safety is paramount. Follow these essential tips to ensure a secure environment while harnessing the power of your generator:

- Positioning Matters:

- Optimal Placement: Place the inverter generator at least 20 feet away from your living or work area to prevent carbon monoxide exposure.

- Ventilation Awareness: Keep the generator in an open space with ample ventilation to dissipate exhaust gases effectively.

- Fueling Caution:

- No-Spill Rule: Refuel the generator only when it’s turned off to minimize the risk of spills.

- Use Fresh Fuel: Utilize fresh, stabilized fuel to maintain the generator’s efficiency and reduce emissions.

- Electrical Connection Safety:

- Proper Grounding: Ensure the generator is grounded correctly to avoid electrical hazards.

- Responsible Use of Extension Cords: Use heavy-duty, grounded extension cords designed for outdoor use to connect appliances.

- Regular Maintenance:

- Scheduled Checks: Perform regular checks on oil levels, air filters, and spark plugs to keep the generator in top condition.

- Follow Manufacturer’s Instructions: Adhere to the manufacturer’s maintenance guidelines for optimal performance.

- Emergency Shutdown Protocol:

- Immediate Response: Familiarize yourself with the emergency shutdown procedure to swiftly turn off the generator in case of any issues.

- Safety First: Prioritize your safety and that of others in case of emergencies.

By adhering to these inverter generator safety tips, you not only safeguard yourself and others but also extend the lifespan of your valuable equipment.

Conclusion

In conclusion, knowing how to set up an inverter generator is a valuable skill that can save you time and hassle in critical moments. By following these steps, you’ve equipped yourself with the expertise to harness the full potential of your generator.

Whether it’s for a camping trip, a backyard event, or ensuring your home stays powered during outages, you now have the confidence to handle it all. Keep this guide handy, and you’ll always be ready to make the most out of your inverter generator. Remember, preparation is the key to seamless power supply, no matter where you are.

References

- Waste heat recovery from thermo-electric generators (TEGs)

- Short run effects of a price on carbon dioxide emissions from US electric generators

- The intermittency of wind, solar, and renewable electricity generators: Technical barrier or rhetorical excuse?

- Control of electric generators: a review