Stranded in the dark with a stubborn generator? Frustrating, isn’t it? When the power source that’s meant to be your lifeline refuses to stay running, panic can set in. Don’t worry; you’re not alone in this power struggle. Discovering what to do if generator won’t stay running is a common challenge that many face. It’s more than a technical hiccup; it’s an inconvenience that disrupts the rhythm of our daily lives.

In this guide, we’ll navigate through troubleshooting tips and unveil the secrets to revive your generator, ensuring you’re never left in the shadows again. Let’s power up your knowledge and your generator!

Jump to a Specific Section

- 1 Core Lessons

- 2 Why Won’t Your Generator Stay Running?

- 3 What to Do if Generator Won’t Stay Running?

- 3.1 Insufficient Fuel

- 3.2 Dirty or Faulty Spark Plug

- 3.3 Airflow Blockages

- 3.4 Low Oil Levels

- 3.5 Battery Issues

- 3.6 Faulty Carburetor

- 3.7 Clogged Fuel Filter

- 3.8 Old or Stale Fuel

- 3.9 Ignition System Problems

- 3.10 Overloaded Generator

- 3.11 Coolant Issues

- 3.12 Automatic Shutdown Features

- 3.13 Wiring Problems

- 3.14 Governor Issues

- 3.15 Exhaust System Blockages

- 3.16 Faulty Voltage Regulator

- 3.17 Engine Overheating

- 3.18 Control Board Malfunctions

- 3.19 Seek Professional Assistance if Necessary

- 4 Generator Maintenance Tips

- 5 Generator Safety Tips

- 6 Conclusion

- 7 References

- 8 Frequently Asked Questions

- 8.1 What should I do if my generator won’t start at all?

- 8.2 How often should I clean or replace the air filter in my generator?

- 8.3 Can a faulty spark plug cause my generator to shut off randomly?

- 8.4 How can I determine if the fuel in my generator is of good quality?

- 8.5 Are there any common signs or symptoms that indicate a problem with the ignition system in my generator?

- 8.6 How do you fix a generator that keeps shutting off?

- 8.7 Why does my generator run for 5 seconds then shut off?

- 8.8 How do I keep my generator running?

Core Lessons

- Troubleshoot components to ensure proper functioning and address any problems found

- Seek professional assistance for complex issues that cannot be resolved through basic maintenance procedures

- Consult with an expert if the generator struggles or fails to start consistently

- Address frequent stalls or unexpected shutdowns by accurately diagnosing and repairing components with the help of a professional technician

Why Won’t Your Generator Stay Running?

Power outages can be stressful, and a reliable generator is crucial for uninterrupted electricity. If you find that your generator won’t stay running, various factors could be causing this issue. Let’s explore 18 common reasons:

- Insufficient Fuel: Running out of fuel or not having enough.

- Dirty or Faulty Spark Plug: Impaired ignition due to a dirty or malfunctioning spark plug.

- Airflow Blockages: Restricted air circulation causing overheating and shutdowns.

- Low Oil Levels: Inadequate oil levels triggering automatic shutdown.

- Battery Issues: Weak or dead battery hindering the starting process.

- Faulty Carburetor: Disrupted fuel-air mixture affecting engine performance.

- Clogged Fuel Filter: Impaired fuel flow due to a blocked filter.

- Old or Stale Fuel: Use of outdated or degraded fuel affecting combustion.

- Ignition System Problems: Issues with ignition coil or module affecting startup.

- Overloaded Generator: Exceeding the generator’s capacity, causing shutdown.

- Coolant Issues: Low coolant levels or blockages affecting temperature regulation.

- Automatic Shutdown Features: Safety features triggering automatic shutdown.

- Wiring Problems: Damaged or loose wiring disrupting electrical connections.

- Governor Issues: Malfunctions in the governor affecting engine speed control.

- Exhaust System Blockages: Obstructions in the exhaust system affecting ventilation.

- Faulty Voltage Regulator: Issues with the voltage regulator affecting power output.

- Engine Overheating: Excessive heat during operation leading to shutdown.

- Control Board Malfunctions: Problems with the control board affecting overall functionality.

Identifying the specific cause will guide you in implementing the appropriate solution to ensure your generator operates reliably. In the next section, we’ll discuss practical fixes for these common generator issues.

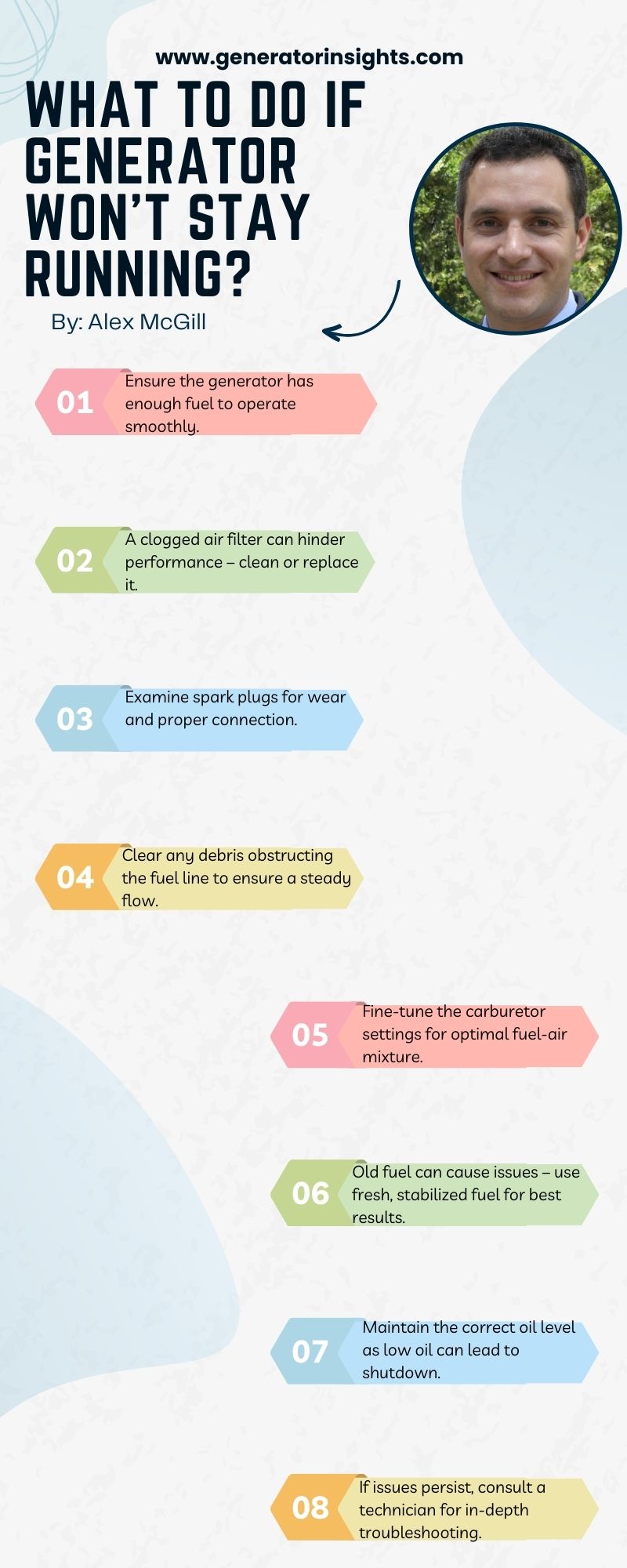

What to Do if Generator Won’t Stay Running?

If your generator won’t stay running, it can be frustrating and concerning, especially during emergencies or power outages. However, several common issues can cause this problem, and with some troubleshooting, you may be able to resolve it.

- Insufficient Fuel: Refill the fuel tank with clean and sufficient fuel.

- Dirty or Faulty Spark Plug: Clean or replace the spark plug as needed.

- Airflow Blockages: Clear debris and ensure proper ventilation.

- Low Oil Levels: Maintain oil levels as per manufacturer recommendations.

- Battery Issues: Charge or replace the battery if necessary.

- Faulty Carburetor: Clean, maintain, or seek professional inspection.

- Clogged Fuel Filter: Replace the fuel filter regularly.

- Old or Stale Fuel: Use fresh fuel and consider fuel stabilizers.

- Ignition System Problems: Address issues with the ignition coil or module.

- Overloaded Generator: Reduce the load or upgrade to a higher capacity generator.

- Coolant Issues: Check and top up coolant levels, address leaks or blockages.

- Automatic Shutdown Features: Identify triggers and reset safety features.

- Wiring Problems: Inspect and repair any damaged or loose wiring.

- Governor Issues: Ensure proper functioning or seek professional assistance.

- Exhaust System Blockages: Clear obstructions for adequate ventilation.

- Faulty Voltage Regulator: Repair or replace the voltage regulator.

- Engine Overheating: Monitor and address issues causing excessive heat.

- Control Board Malfunctions: Test and repair problems with the control board.

Addressing these specific issues will help resolve the problem and ensure your generator runs smoothly.

Now let’s discuss these fixes in detail.

Insufficient Fuel

When your generator won’t stay running, one of the first factors to inspect is the fuel supply. An insufficient fuel level or an empty tank can lead to unexpected shutdowns. To remedy this, refill the fuel tank with clean and sufficient fuel. Ensure that the fuel used is of high quality and free from contaminants, as impurities can clog the fuel system, affecting the generator’s performance.

Regularly checking and maintaining the fuel levels is essential for the proper functioning of the generator. Implementing a routine fuel check, especially before an anticipated period of use, can prevent interruptions in power generation during critical times. By prioritizing a consistent and adequate fuel supply, you contribute to the reliability of your generator during power outages.

Dirty or Faulty Spark Plug

A crucial component in the ignition system, the spark plug plays a pivotal role in starting and maintaining your generator’s operation. When facing issues with a generator that won’t stay running, a common culprit could be a dirty or faulty spark plug.

Cleaning the spark plug is a simple yet effective solution. Remove the spark plug and inspect it for dirt, carbon deposits, or wear. Use a wire brush or specialized cleaner to carefully remove any contaminants. If cleaning doesn’t resolve the issue, consider replacing the spark plug with a new, compatible one.

Regular maintenance of the spark plug is essential for optimal performance. By addressing spark plug issues, you ensure a consistent and efficient ignition process, contributing to the overall reliability of your generator.

Airflow Blockages

Proper ventilation is crucial for the optimal functioning of a generator. Airflow blockages can lead to overheating, triggering automatic shutdowns to prevent damage. To ensure your generator won’t encounter disruptions due to restricted air circulation, it’s important to take the following steps:

- Clear Debris: Regularly inspect the generator’s surroundings for debris, leaves, or other obstructions that may impede airflow. Clear any accumulated material to allow for efficient ventilation.

- Ventilation System Maintenance: Check and maintain the generator’s ventilation system. Ensure that vents and openings are free from dirt or blockages. Clean or replace filters as recommended by the manufacturer.

Addressing these issues helps maintain the generator’s optimal operating temperature, preventing overheating-related shutdowns and promoting continuous and reliable power supply during outages. Regular attention to airflow ensures the longevity and effectiveness of your generator.

Low Oil Levels

Proper oil levels are crucial for the smooth operation of your generator. Low oil levels can trigger automatic shutdown mechanisms to prevent engine damage. To address this issue and ensure your generator stays running:

- Regular Oil Checks: Establish a routine for checking and maintaining oil levels according to the manufacturer’s recommendations. This preventive measure helps avoid unexpected shutdowns and ensures continuous operation during power outages.

- Oil Quality: Besides quantity, the quality of the oil is essential. Ensure you use the recommended type of oil for your generator and replace it at regular intervals. Dirty or degraded oil can affect engine performance.

By maintaining optimal oil levels and quality, you contribute to the longevity of your generator, reduce the risk of engine damage, and enhance its reliability during critical times.

Battery Issues

A reliable battery is essential for the startup and continuous operation of your generator. When facing challenges with a generator that won’t stay running, it’s crucial to address potential battery issues:

- Charge the Battery: If the battery is weak or dead, charging it can often resolve the problem. Ensure that the battery is properly charged before attempting to start the generator.

- Battery Replacement: If the battery no longer holds a charge or is consistently weak, consider replacing it with a new, compatible battery. This is especially important for generators that rely on electric starters.

- Regular Maintenance: Implement a routine battery maintenance schedule, including cleaning terminals and checking connections. Well-maintained batteries are more likely to provide consistent and reliable power.

Addressing battery-related issues ensures the smooth startup and operation of your generator, contributing to its overall reliability during power outages. Regular maintenance helps extend the life of the battery and minimizes the risk of unexpected shutdowns.

Faulty Carburetor

The carburetor is a critical component of the fuel system that ensures the proper mixture of air and fuel for combustion. A faulty carburetor can disrupt this balance and lead to issues with your generator staying running. Here’s how to address this problem:

- Regular Cleaning: Periodically clean the carburetor to remove any dirt, varnish, or residue that may accumulate. Use a carburetor cleaner and follow the manufacturer’s guidelines for cleaning.

- Maintenance or Replacement: If cleaning doesn’t resolve the issue, consider seeking professional maintenance or replacing the carburetor. A malfunctioning carburetor may require expert attention to ensure proper functionality.

- Fuel Quality: Use high-quality fuel and consider adding a fuel stabilizer if the generator will be stored for an extended period. Poor-quality fuel can contribute to carburetor issues.

Proper care and attention to the carburetor contribute to the efficient operation of your generator, ensuring a consistent fuel-air mixture and reliable performance during power outages. Regular maintenance helps prevent disruptions and extends the life of the generator.

Clogged Fuel Filter

A clogged fuel filter can impede the flow of fuel to the engine, causing your generator to stall or not stay running. Addressing this issue involves the following steps:

- Regular Replacement: Replace the fuel filter at regular intervals, as recommended by the manufacturer. This preventive measure ensures a clean and unobstructed fuel flow.

- Inspect for Contaminants: Periodically inspect the fuel filter for any signs of contamination, such as dirt or debris. If visible, clean or replace the filter as needed.

- Quality Fuel: Use high-quality, clean fuel to minimize the risk of filter clogging. Contaminated fuel can lead to premature clogging and affect the generator’s performance.

By maintaining a clean fuel filter, you ensure a consistent and reliable fuel supply to the engine, contributing to the overall efficiency and longevity of your generator. Regular inspections and replacements are key preventive measures.

Old or Stale Fuel

Using old or stale fuel in your generator can lead to combustion issues and disrupt its continuous operation. To address this problem:

- Fuel Replacement: Drain and replace the old fuel with fresh, high-quality fuel. Stale fuel can lead to varnish buildup and affect the generator’s performance.

- Fuel Stabilizers: Consider using fuel stabilizers, especially if the generator will be stored for an extended period. Stabilizers help prevent fuel degradation and maintain its quality over time.

- Regular Fuel Checks: Periodically check the fuel in the tank for freshness. Avoid using fuel that has been stored for an extended period, as it may have deteriorated.

Maintaining a fresh and clean fuel supply is essential for the proper functioning of your generator.

Ignition System Problems

Issues within the ignition system can lead to a generator not staying running. To address problems in this critical component:

- Inspect Ignition Components: Regularly check the ignition coil, spark plug, and other components for signs of wear or damage. Replace any faulty parts promptly.

- Clean or Replace Spark Plug: Ensure the spark plug is clean and functioning correctly. Cleaning or replacing it can improve the ignition process.

- Check Ignition Timing: If applicable, verify that the ignition timing is accurate. Incorrect timing can lead to misfires and shutdowns.

- Professional Inspection: If ignition problems persist, seek professional inspection and maintenance to address underlying issues in the ignition system.

By maintaining a well-functioning ignition system, you ensure a reliable and consistent startup, contributing to the overall performance and longevity of your generator during power outages.

Overloaded Generator

Exceeding the generator’s capacity can lead to instability, shutdowns, and potential damage. To address this issue:

- Check Power Requirements: Ensure that the total electrical load connected to the generator does not exceed its rated capacity. Check the power requirements of each device or appliance.

- Prioritize Essential Loads: During an outage, prioritize essential appliances and devices. Disconnect non-essential items to reduce the load on the generator.

- Upgrade if Necessary: If your power needs consistently exceed the generator’s capacity, consider upgrading to a higher-capacity generator to meet the demands of your household or business.

By managing the electrical load effectively, you prevent overloading, ensuring the stable operation of your generator and maintaining a reliable power supply during outages. Understanding and respecting the generator’s capacity is crucial for optimal performance.

Coolant Issues

Issues with the coolant system can lead to overheating and automatic shutdowns in a generator. Address coolant-related problems with the following steps:

- Check Coolant Levels: Regularly inspect the coolant levels in the generator. Ensure they are within the recommended range. Top up coolant as needed.

- Address Leaks: Identify and address any coolant leaks promptly. Leaks can lead to low coolant levels and subsequent overheating.

- Coolant Quality: Use the recommended coolant type and ensure it is in good condition. Regularly replace coolant according to the manufacturer’s guidelines.

By maintaining proper coolant levels and addressing any issues promptly, you help regulate the temperature of the generator’s engine. This, in turn, prevents overheating-related shutdowns and ensures continuous and reliable power generation during outages. Regular checks and maintenance contribute to the overall health of your generator.

Automatic Shutdown Features

Generators are equipped with automatic shutdown features to protect the engine and other components from damage. To address issues related to automatic shutdown features:

- Identify Triggers: Determine the specific conditions that trigger the automatic shutdown. Common triggers include low oil levels, high engine temperature, or overloading.

- Reset Safeties: Once the triggers are identified and addressed, reset the automatic shutdown features according to the manufacturer’s instructions.

- Address Underlying Issues: Investigate and resolve the underlying issues that led to the automatic shutdown. This may involve fixing oil leaks, resolving overheating problems, or adjusting the electrical load.

Understanding and managing the automatic shutdown features of your generator ensures the safety and longevity of the equipment. Regular checks and timely resolution of triggers contribute to a reliable and uninterrupted power supply during outages.

Wiring Problems

Issues with the wiring of your generator can disrupt electrical connections and lead to shutdowns. To address wiring problems:

- Inspect Wiring: Regularly inspect the wiring for any signs of damage, wear, or loose connections. Damaged or compromised wiring can interrupt the electrical flow.

- Repair or Replace: If you identify any issues with the wiring, repair or replace the damaged sections promptly. Ensure all connections are secure and properly insulated.

- Professional Inspection: If you’re uncertain about the condition of the wiring or if issues persist, consider seeking professional inspection and repair. A qualified technician can identify and address wiring problems effectively.

Maintaining a sound electrical wiring system is crucial for the reliable operation of your generator. Regular inspections and timely repairs contribute to a stable and uninterrupted power supply during outages.

Governor Issues

The governor in a generator plays a vital role in controlling and regulating the engine speed. If there are problems with the governor, it can affect the generator’s performance. To address governor-related issues:

- Check Governor Settings: Ensure that the governor is set to the correct speed according to the manufacturer’s specifications. Incorrect settings can lead to instability.

- Governor Maintenance: Regularly maintain the governor by cleaning and lubricating it as per the manufacturer’s guidelines. This ensures smooth operation and accurate speed control.

- Professional Assistance: If you encounter persistent governor issues or are unsure about the maintenance process, consider seeking professional assistance. A technician can inspect, adjust, or replace the governor as needed.

Proper governor function is essential for maintaining a consistent and stable engine speed, contributing to the overall reliability of your generator during power outages. Regular maintenance helps prevent disruptions and ensures optimal performance.

Exhaust System Blockages

A clear and unobstructed exhaust system is crucial for proper ventilation and the efficient operation of your generator. To address blockages in the exhaust system:

- Inspect Exhaust Components: Regularly inspect the exhaust system for any signs of blockages, such as debris, nests, or other obstructions. Ensure the exhaust pipe and muffler are free from restrictions.

- Clear Obstructions: If blockages are detected, carefully clear them to restore proper airflow. Be cautious when working near the exhaust system, especially when the generator is hot.

- Periodic Maintenance: Implement a periodic maintenance schedule for the exhaust system. Clean or replace components as necessary, and ensure that the exhaust gases can escape freely.

Maintaining a clear exhaust system prevents overheating, enhances ventilation, and ensures the efficient operation of your generator. Regular checks contribute to the overall reliability and performance during power outages.

Faulty Voltage Regulator

The voltage regulator in a generator is responsible for maintaining a steady output voltage. If the voltage regulator malfunctions, it can lead to irregular power supply. To address issues with the voltage regulator:

- Voltage Checks: Regularly monitor the output voltage of the generator. If you notice fluctuations or irregularities, it may indicate a problem with the voltage regulator.

- Adjustment or Replacement: Depending on the type of voltage regulator, it may be possible to adjust settings. However, if the regulator is faulty, consider replacing it to ensure stable voltage output.

- Professional Inspection: For complex issues or if you are unsure about the condition of the voltage regulator, seek professional inspection and, if necessary, replacement. A qualified technician can diagnose and address voltage regulation problems effectively.

A properly functioning voltage regulator is crucial for delivering a consistent and stable power supply. Regular checks and timely adjustments or replacements contribute to the overall reliability of your generator during power outages.

Engine Overheating

Engine overheating can be a critical issue that triggers automatic shutdowns in generators. To address this concern:

- Monitor Temperature: Keep an eye on the generator’s temperature gauge. If it consistently reads high or reaches dangerous levels, it indicates potential overheating.

- Check Coolant Levels: Inspect the coolant levels and top up if necessary. Low coolant levels can contribute to overheating.

- Clear Airflow Paths: Ensure proper ventilation around the generator. Remove any debris or obstructions that might impede airflow and contribute to overheating.

- Inspect Radiator and Fans: Regularly inspect the radiator and cooling fans. Clean or replace them as needed to maintain efficient heat dissipation.

- Professional Inspection: If overheating persists or if you’re uncertain about the cause, seek professional inspection. A technician can identify and address underlying issues contributing to engine overheating.

Proactive monitoring and addressing overheating concerns contribute to the longevity and reliable performance of your generator during power outages. Regular maintenance is key to preventing disruptions.

Control Board Malfunctions

The control board, also known as the generator’s electronic control module (ECM) or panel, is responsible for regulating various functions. If the control board malfunctions, it can impact the overall performance of the generator. To address issues related to control board malfunctions:

- Check for Error Codes: Modern generators often have diagnostic features that display error codes. Check the control panel for any error messages or codes that indicate issues with the control board.

- Inspect Wiring Connections: Ensure that all wiring connections to the control board are secure and free from damage. Loose or damaged connections can disrupt communication and functionality.

- Power Cycling: In some cases, power cycling the generator by turning it off and then on again may reset the control board. However, this is a temporary solution, and if issues persist, further investigation is needed.

- Professional Assistance: If you are unable to identify or resolve control board malfunctions, seek professional assistance. A qualified technician can conduct a thorough inspection, diagnose the problem, and perform any necessary repairs or replacements.

A well-functioning control board is essential for the proper operation of your generator. Regular checks and prompt resolution of control board issues contribute to the overall reliability during power outages.

Seek Professional Assistance if Necessary

If all else fails and the generator persists in its obstinate refusal to function properly, it may be prudent to enlist the aid of a knowledgeable professional to diagnose and rectify any underlying complexities. Seeking professional assistance is crucial when troubleshooting common generator issues that cannot be resolved through basic maintenance procedures.

Here are some signs that indicate a need for professional generator repair:

- Persistent engine starting problems: If the generator struggles or fails to start consistently despite proper fuel and ignition system inspection, it is advisable to consult with an expert who can identify and address any mechanical or electrical malfunctions.

- Continuous stalling or shutdowns: If the generator frequently stalls or shuts down unexpectedly during operation, there may be serious issues with components such as the carburetor, fuel pump, voltage regulator, or alternator. A professional technician will have the expertise to diagnose these problems accurately and perform repairs accordingly.

When seeking professional assistance, it is essential to choose a reputable service provider with experience in generator repair. They will possess specialized knowledge and diagnostic tools necessary for identifying complex issues that may not be apparent even after thorough inspection by an untrained individual.

By relying on their expertise, one can ensure a timely resolution of the generator’s malfunctioning and prevent further damage from occurring.

If interested you can also read about the generator vs inverter here. Moreover, you can read about portable vs standby generator here.

Generator Maintenance Tips

Ensuring your generator runs smoothly is crucial for uninterrupted power supply. Regular maintenance not only extends its lifespan but also prevents costly breakdowns. Here are essential tips to keep your generator in peak condition:

- Scheduled Inspections: Conduct thorough visual inspections every month, checking for loose wires, leaks, and any signs of wear and tear.

- Oil Level Check: Regularly monitor the oil levels. Low oil can lead to engine damage. Follow the manufacturer’s guidelines for the correct oil type and change intervals.

- Air Filter Replacement: Clean or replace the air filter as recommended by the manufacturer. A clogged filter reduces efficiency and can strain the generator.

- Fuel System Maintenance: Ensure the fuel system is clean and free of contaminants. Use a fuel stabilizer if the generator is not in frequent use to prevent fuel degradation.

- Battery Inspection: Check the battery terminals for corrosion and ensure they are tightly connected. Weak batteries can hinder starting and overall performance.

- Cooling System Care: Inspect the cooling system for debris and make sure the radiator fins are clean. Overheating can cause serious damage to the generator.

- Run the Generator Monthly: Even if there’s no power outage, run the generator for a short period each month. This keeps internal parts lubricated and ensures it’s ready when needed.

- Keep a Log: Maintain a maintenance log, noting each inspection, oil change, and part replacement. This log helps in tracking the generator’s health and aids in timely preventive measures.

Following these generator maintenance tips diligently ensures that your power backup system is reliable and ready to serve when required.

Generator Safety Tips

Generators are invaluable during power outages, but it’s crucial to prioritize safety. Follow these tips to ensure the proper and secure use of your generator:

- Outdoor Placement: Always operate your generator outdoors to prevent the buildup of harmful fumes. Maintain a safe distance from windows and doors.

- Ventilation: Adequate ventilation is essential. Keep the generator in an open space to disperse exhaust fumes and reduce the risk of carbon monoxide poisoning.

- Dry Environment: Place the generator on a dry surface to avoid electrical hazards. Keep it away from puddles or wet areas to prevent the risk of electric shock.

- Grounding: Properly ground the generator to reduce the risk of electric shock. Follow the manufacturer’s guidelines for grounding procedures.

- Fuel Storage: Store fuel in approved containers in a cool, well-ventilated area, away from living spaces. Never store fuel near the generator while it’s running.

- Fire Safety: Keep a fire extinguisher nearby and know how to use it. Generator engines can get hot, and having a fire safety tool on hand is crucial.

- Carbon Monoxide Alarms: Install carbon monoxide alarms in your home, especially in sleeping areas. These detectors can provide early warnings if dangerous levels of carbon monoxide are detected.

- Turn Off Before Refueling: Always turn off the generator and let it cool down before refueling. Spilled fuel on hot engine parts can lead to fires.

- Extension Cords: Use only heavy-duty extension cords designed for outdoor use. Ensure they are in good condition and rated for the wattage of your generator.

- Regular Maintenance: Follow the manufacturer’s guidelines for maintenance. Regularly check oil levels, filters, and other components to keep the generator running smoothly.

Remember, prioritizing safety when using generators is essential for both your well-being and the longevity of your equipment.

Conclusion

In conclusion, What to Do If Generator Won’t Stay Running empowers you to become a savvy generator owner, capable of diagnosing and resolving issues that hinder its operation. By adhering to our troubleshooting tips and taking proactive maintenance measures, you can ensure that your generator remains reliable during times of need.

Remember to regularly inspect and service your generator to prevent future problems and extend its lifespan. As you venture into the realm of generator ownership, let this guide be your go-to resource, guiding you through challenges and ensuring your generator always performs at its best.

References

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

- Stabilization of two electricity generators

- Electrical generators for direct drive wave energy converters

- Waste heat recovery from thermo-electric generators (TEGs)

Frequently Asked Questions

What should I do if my generator won’t start at all?

If a generator fails to start, there are several troubleshooting tips to consider. Common reasons for this issue include fuel problems, ignition system malfunctions, or mechanical issues. Identifying and addressing these factors can help resolve the problem efficiently and effectively.

How often should I clean or replace the air filter in my generator?

The recommended frequency for cleaning or replacing the air filter in a generator depends on usage and environmental conditions. Signs of a clogged air filter may include decreased engine performance, increased fuel consumption, and difficulty starting the generator.

Can a faulty spark plug cause my generator to shut off randomly?

A faulty spark plug can potentially cause a generator to shut off randomly due to a faulty ignition. Troubleshooting the spark plug involves examining its condition, checking for proper connection, and ensuring the correct spark plug is being used.

How can I determine if the fuel in my generator is of good quality?

Testing fuel quality is crucial to determine if there is fuel contamination in a generator. Various tests, such as visual inspection, water separation, and fuel analysis, can be conducted to assess the purity of the fuel and ensure optimal generator performance.

Are there any common signs or symptoms that indicate a problem with the ignition system in my generator?

Common signs and symptoms of a faulty ignition system in a generator include difficulty starting, engine misfiring, stalling, or sudden shutdowns. These issues can be caused by spark plug problems, ignition coil malfunctions, or fuel delivery issues.

How do you fix a generator that keeps shutting off?

To address a generator repeatedly shutting off, one should first try running the generator with fewer connected loads by unplugging some devices. Ensure the fuel shut-off valve is fully open, as insufficient gas flow can impede proper engine function. If the valve is open, inspect the fuel filter and line for potential clogs.

Why does my generator run for 5 seconds then shut off?

If a generator runs for a brief period (5 seconds) before shutting down, it may be due to improper oil levels. Low oil levels cause a rapid temperature increase, triggering an automatic shutdown. Check and adjust the oil level within the recommended range to ensure proper generator operation.

How do I keep my generator running?

To maintain a generator’s consistent operation, it’s crucial to adopt several practices. Keep the generator clean, regularly empty the fuel tank, and have spare fuel and oil filters on hand. Avoid overloading the generator, store an appropriate amount of fuel, choose quality fuel, and dispose of any deteriorated fuel. Additionally, routine checks of the oil level contribute to sustained generator performance.