In a world where power outages can disrupt our daily lives, the question arises: Can you hook 2 portable generators together to amplify your power supply? Picture this: you’re in the midst of a blackout, and a single generator might not be cutting it. Here’s where the curiosity kicks in, as individuals seek ways to enhance their energy solutions.

Whether you’re a camping enthusiast or facing an unexpected outage, the prospect of doubling your generator power becomes a beacon of hope. Let’s embark on a journey to unravel the possibilities and discover how connecting two portable generators might just be the key to ensuring uninterrupted power when you need it most.

Jump to a Specific Section

- 1 TLDR

- 2 What is a Portable Generator and How It Works?

- 3 How Does a Portable Generator Produce Power?

- 4 What is Paralleling?

- 5 Can You Hook 2 Portable Generators Together?

- 6 How to Safely Connect Two Portable Generators?

- 7 Why Do You Need to Run Two Portable Generators in Parallel?

- 8 How Generator Parallel Kits Work?

- 9 Benefits of Running Two Portable Generators in Parallel

- 10 Tips to Safely Run Two Portable Generators in Parallel

- 11 Common Mistakes to Avoid When Connecting Two Portable Generators

- 12 Troubleshooting Common Generator Paralleling Issues

- 13 Parallel Generators Maintenance Tips

- 14 Parallel Generators Safety Tips

- 15 Conclusion

- 16 References

- 17 Frequently Asked Questions

- 17.1 Can I Connect More Than Two Portable Generators Together?

- 17.2 Is It Possible to Connect Generators of Different Wattage or Brand?

- 17.3 Can I Connect Generators of Different Fuel Types (E.G., Gasoline and Propane)?

- 17.4 What Are the Limitations or Risks Associated With Connecting Multiple Generators?

- 17.5 Can I Connect Portable Generators With Different Output Voltage Levels?

- 17.6 What are the things to be considered while installing two generators parallelly?

- 17.7 Can generators be connected in series?

- 17.8 Can you parallel two non-inverter generators?

TLDR

- Connecting multiple portable generators allows for increased overall power output and efficiency.

- Generator synchronization is crucial for seamless and efficient power generation, considering factors such as frequency, voltage, and phase angle.

- Proper generator grounding is essential for safety and reliable operation of the electrical system.

- Safety considerations, such as avoiding voltage overload and following manufacturer guidelines, should be followed when linking portable generators.

What is a Portable Generator and How It Works?

A Portable Generator is a versatile device designed to provide a convenient and temporary source of electrical power. These compact machines are particularly useful in situations where a reliable electrical supply is not readily available, such as during power outages, outdoor events, or construction projects. The key advantage of a portable generator lies in its mobility, allowing users to easily transport and deploy it wherever power is required.

Portable generators typically operate on various fuels, including gasoline, propane, or diesel. The basic working principle involves converting mechanical energy into electrical energy through a process known as electromagnetism. Inside the generator, a small engine, powered by the chosen fuel, turns an alternator, which consists of a rotor and a stator. As the rotor spins within a magnetic field created by the stator, it induces an electrical current. This alternating current (AC) is then processed through a built-in inverter to produce the desired electrical output suitable for powering a range of devices, from lights and appliances to electronic gadgets.

One of the notable features of portable generators is their user-friendly control panel, where individuals can easily start or stop the unit and regulate the power output. Additionally, many models come equipped with safety features such as circuit breakers to protect against overloads. While portable generators offer a convenient solution for temporary power needs, it’s essential to operate them safely by following manufacturer guidelines.

How Does a Portable Generator Produce Power?

Portable generators are versatile devices that provide on-the-go electrical power. Understanding how they produce power involves breaking down the process into key components:

- Engine: The generator houses an internal combustion engine, often fueled by gasoline or propane. This engine is responsible for converting chemical energy from the fuel into mechanical energy.

- Mechanical Energy: As the engine runs, it spins a shaft, generating mechanical energy. This rotational force is a crucial intermediary step in the power generation process.

- Alternator: Connected to the engine’s shaft is an alternator, also known as a generator head. The alternator contains a coil of wire that rotates within a magnetic field. This rotation induces an alternating current (AC) in the wire.

- Conversion to Electricity: The generated AC is not yet suitable for most household appliances, which operate on direct current (DC). To make it usable, the AC is passed through a component called a rectifier, which converts it into DC.

- Voltage Regulation: The portable generator includes a voltage regulator to maintain a consistent voltage level. This is crucial for protecting connected devices from potential damage caused by voltage fluctuations.

- Power Outlets: Finally, the converted and regulated electricity is sent to the generator’s power outlets. These outlets allow you to plug in various devices, from lights to appliances, drawing power as needed.

What is Paralleling?

Paralleling generators refers to the practice of connecting multiple power generators to operate together in a synchronized and coordinated manner. This is a common approach in power systems to achieve higher power output, enhance system reliability, and facilitate flexibility in managing loads. When generators are paralleled, they share the electrical load, with each generator contributing a portion of the total power required. This process is crucial for balancing the demand for electricity and ensuring a stable power supply.

To understand the concept better, imagine a scenario where a single generator is unable to meet the entire electricity demand of a facility or a community. In such cases, additional generators can be brought online and connected in parallel. The synchronization process involves matching the voltage, frequency, and phase angle of the incoming generator with those of the existing power supply. Once synchronized, the generators work together seamlessly, distributing the load effectively.

Can You Hook 2 Portable Generators Together?

No, you cannot directly connect two portable generators together. Attempting to do so can result in electrical hazards, damage to the generators, and potential harm to connected devices or systems.

Portable generators are designed to operate independently and are not equipped with the necessary hardware to safely synchronize their output. Attempting to connect them directly can cause phase mismatches, which can lead to voltage spikes, electrical fires, or damage to connected equipment.

If you need more power than one generator can provide, it is recommended to use a parallel kit or a transfer switch with a compatible generator. A parallel kit allows you to connect two generators of the same model, brand, and wattage together safely. This synchronizes their outputs and effectively doubles the power capacity.

Using a transfer switch allows you to connect multiple generators to a central distribution panel, ensuring a balanced load distribution. This setup is commonly used in backup power systems for homes or businesses.

Always consult the user manuals and guidelines provided by the generator manufacturer for specific instructions on safe operation and parallel connection options.

How to Safely Connect Two Portable Generators?

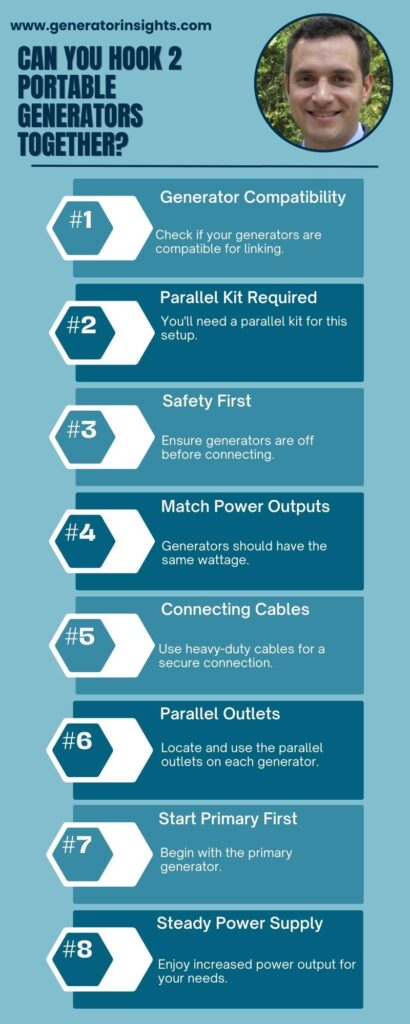

Paralleling two generators can significantly enhance power output, making it a practical solution in scenarios where increased electrical capacity is required. Parallel operation involves connecting two generators to work together seamlessly, sharing the load. This guide will walk you through the step-by-step process of paralleling generators, ensuring a smooth and efficient power supply.

Step 1: Check Generator Compatibility

Before attempting to parallel two generators, it’s crucial to confirm that they are compatible for parallel operation. Check the manufacturer’s specifications and user manuals for both generators. Ensure that they have the same voltage rating, frequency, and are equipped with a parallel operation capability.

Step 2: Prepare the Generators

- Set the Operating Parameters: Adjust the operating parameters on both generators to match each other precisely. This includes synchronizing the voltage, frequency, and any other relevant settings.

- Turn Off Automatic Voltage Regulator (AVR): Disable the AVR on both generators. This ensures that each generator adjusts its voltage based on the load it is carrying, allowing for a balanced distribution of power.

Step 3: Connect the Generators

- Use Parallel Cables: Connect the generators using specialized parallel cables designed for this purpose. These cables facilitate communication between the generators, enabling them to synchronize and share the load evenly.

- Ensure Proper Phasing: Check and ensure that the generators are in phase with each other. This is critical for maintaining a stable and synchronized power supply.

Step 4: Synchronize the Generators

- Start the Generators: Begin by starting one generator and allowing it to stabilize. Then, start the second generator.

- Adjust Frequency and Voltage: Use the built-in controls to adjust the frequency and voltage of the generators until they match. Some generators come equipped with automatic synchronization features, simplifying this process.

Step 5: Load Sharing

- Activate Load Sharing: Once the generators are synchronized, activate the load-sharing function. This allows the generators to distribute the electrical load evenly, preventing one generator from taking on more load than the other.

- Monitor System Parameters: Continuously monitor the system parameters, including voltage, frequency, and load distribution, to ensure that both generators are operating within their specified limits.

By following these steps, you can successfully parallel two generators, providing a reliable and efficient power supply tailored to your specific needs.

Why Do You Need to Run Two Portable Generators in Parallel?

When it comes to power generation, the use of generators plays a crucial role in meeting our energy needs. However, there’s a growing trend toward employing multiple generators simultaneously, a practice known as parallel generation. Let’s explore why this approach is gaining popularity and the benefits it offers.

- Enhanced Reliability:

- Parallel generators provide a reliable backup in case one generator fails. If a single unit malfunctions, the others can seamlessly take over, ensuring a continuous and uninterrupted power supply.

- Increased Power Output:

- Parallel operation allows for the combined output of multiple generators, resulting in a higher overall power capacity. This is especially beneficial in situations where a higher energy demand needs to be met.

- Efficient Load Sharing:

- When generators operate in parallel, they can share the load more efficiently. This prevents individual units from being overloaded and promotes a balanced distribution of the power demand among the generators.

- Fuel Efficiency:

- Running generators in parallel at partial loads can contribute to improved fuel efficiency. Instead of operating a single generator at low loads, which is often less efficient, multiple generators can collectively handle the load more optimally.

- Scalability:

- Parallel generators offer a scalable solution for varying power requirements. As demand increases, additional generators can be added to the system, providing a flexible and cost-effective way to adapt to changing energy needs.

- Maintenance Flexibility:

- Parallel operation facilitates easier maintenance schedules. When one generator is taken offline for maintenance or repairs, the others can continue to supply power, reducing downtime and ensuring a more consistent energy supply.

How Generator Parallel Kits Work?

Generator parallel kits are essential accessories for those looking to enhance the power output and flexibility of their generators. These kits are designed to enable the simultaneous operation of multiple generators, creating a combined power source that can handle higher loads than a single unit alone. Generator parallel kits typically consist of a parallel connection box, special cables, and connectors. The connection box facilitates the synchronization of multiple generators by balancing the electrical output and ensuring they work together seamlessly.

To understand how generator parallel kits work, it’s crucial to grasp the concept of parallel connection. In a parallel setup, each generator operates independently but shares the load with others. The parallel connection box constantly monitors and adjusts the voltage and frequency of each generator to maintain a synchronized and harmonious power output. This enables users to combine the wattage of individual generators, providing a more robust power supply to meet increased energy demands.

One significant advantage of using generator parallel kits is the scalability they offer. Users can connect generators of varying sizes and brands, maximizing their power capacity based on specific needs. For instance, if you have two generators with a capacity of 2000 watts each, using a parallel kit would effectively provide a combined output of 4000 watts. This flexibility is particularly useful in situations where additional power is required for RVs, camping, construction sites, or during power outages.

In summary, generator parallel kits enhance the overall power capabilities by allowing multiple generators to work together efficiently. This practical solution ensures a reliable and scalable power source, offering users the flexibility to adapt to changing energy requirements without the need for a larger, single generator.

Benefits of Running Two Portable Generators in Parallel

This setup offers several benefits:

| Benefit | Explanation |

|---|---|

| Increased Power Output | Running two generators in parallel effectively doubles the available power, providing more electricity for demanding tasks or equipment. |

| Improved Reliability | Parallel operation enhances reliability as if one generator fails, the other can continue to supply power, minimizing downtime and ensuring a continuous power source. |

| Flexibility in Power Management | Parallel generators allow for flexibility in distributing power. You can allocate the load between generators based on specific requirements, optimizing fuel efficiency. |

| Scalability for Growing Power Needs | This setup provides a scalable solution. As power needs grow, additional generators can be added to the parallel system, adapting to increased demands effortlessly. |

| Redundancy for Critical Applications | In scenarios where a constant power supply is crucial, parallel generators offer redundancy—an extra layer of assurance against unexpected power failures. |

Tips to Safely Run Two Portable Generators in Parallel

When running two generators in parallel, efficiency and proper management become crucial. Here are some tips to ensure a smooth operation.

- Synchronize Voltage and Frequency:

- Maintain consistent voltage and frequency between the generators to prevent potential damage to connected devices.

- Match Generator Capacities:

- Use generators with similar power capacities to avoid overloading one while underutilizing the other.

- Parallel Connection Setup:

- Follow the manufacturer’s guidelines for proper parallel connection, ensuring a secure and stable configuration.

- Automatic Voltage Regulators (AVRs):

- Ensure both generators are equipped with effective AVRs to automatically adjust voltage fluctuations, maintaining a stable output.

- Load Sharing Control:

- Implement a reliable load-sharing control system to distribute the load evenly between the generators, preventing imbalance and optimizing performance.

- Synchronization Panel:

- Utilize a synchronization panel to align the generators’ phases precisely, preventing electrical conflicts and ensuring seamless parallel operation.

- Proper Grounding:

- Establish a robust grounding system for both generators to enhance safety and minimize the risk of electrical issues.

- Regular Maintenance:

- Conduct routine maintenance checks on both generators to identify and address any issues promptly, ensuring long-term reliability.

- Emergency Shutdown Procedures:

- Establish clear emergency shutdown procedures, enabling a quick response in case of any abnormalities or malfunctions during parallel operation.

Remember, proper synchronization and load management are key to successfully running two generators in parallel, ensuring a reliable and efficient power supply.

Common Mistakes to Avoid When Connecting Two Portable Generators

When running two generators in parallel, it’s crucial to be mindful of certain common mistakes that can hinder efficiency and performance. Here are some key points to consider:

| Mistake | Explanation |

|---|---|

| Insufficient Power Supply | Ensure that both generators receive an adequate power supply to avoid performance issues. Inadequate power can lead to equipment damage and system failures. |

| Mismatched Generator Capacities | Use generators with compatible capacities. Mismatched capacities may lead to overloading or underutilization, impacting overall efficiency. |

| Incorrect Synchronization | Proper synchronization is vital to prevent power imbalances and ensure seamless operation. Incorrect synchronization can lead to equipment damage and safety hazards. |

| Neglecting Load Distribution | Distribute the load evenly between the generators to prevent one from overworking while the other remains underutilized. This promotes optimal performance and longevity. |

| Inadequate Maintenance | Regularly conduct maintenance checks on both generators to identify and address issues promptly. Neglecting maintenance can result in unexpected breakdowns. |

By avoiding these common mistakes, you can ensure the smooth and effective operation of two generators running in parallel.

Troubleshooting Common Generator Paralleling Issues

In generator paralleling systems, combining multiple generators is a common practice to enhance power capacity and reliability. However, certain issues may arise, affecting the seamless operation of these parallel systems. Let’s explore some common problems and their troubleshooting solutions.

| Issue | Symptoms | Possible Causes | Troubleshooting Steps |

|---|---|---|---|

| 1. Load Imbalance | Uneven distribution of power among paralleled generators, leading to inefficiencies. | – Faulty load-sharing mechanisms. – Differences in generator set points. | – Verify Load Sharing: Check and recalibrate load-sharing devices. – Adjust Set Points: Ensure that generator set points are consistent. |

| 2. Frequency Drift | Variances in output frequency among generators, impacting system stability. | – Engine speed deviations. – Incorrect governor settings. | – Governor Calibration: Adjust governor settings to maintain consistent engine speed. – Engine Synchronization: Ensure all engines are synchronized for uniform frequency. |

| 3. Voltage Fluctuations | Unstable voltage levels compromising equipment performance. | – Voltage regulator malfunctions. – Poor connection points. | – Regulator Inspection: Check and recalibrate voltage regulators. – Connection Checks: Examine electrical connections for loose or damaged components. |

| 4. Sudden Load Changes | Inconsistent responses to load variations, affecting overall system reliability. | – Slow response time in load-sharing systems. – Inadequate communication between generators. | – Upgrade Load-Sharing Systems: Implement faster load-sharing devices. – Enhance Communication Protocols: Ensure efficient communication between generators. |

| 5. Overloading | Excessive load on one or more generators, risking equipment damage. | – Incorrect load distribution. – Generator capacity miscalculations. | – Load Redistribution: Balance loads evenly among generators. – Capacity Review: Reevaluate generator capacities to prevent overloading. |

Understanding these common issues and their troubleshooting steps is essential for maintaining the reliability and efficiency of paralleled generator systems. Regular inspections and proactive measures can significantly contribute to the smooth operation of such power setups.

Parallel Generators Maintenance Tips

- Regular Inspection: Perform scheduled inspections on parallel generators to identify and address potential issues before they escalate.

- Fluid Levels Check: Regularly check oil, coolant, and fuel levels to ensure optimal performance and prevent damage due to inadequate lubrication or overheating.

- Run Test: Conduct periodic load bank tests to verify that each generator can handle its share of the load, ensuring they are ready for simultaneous operation during peak demand.

- Belt and Hose Inspection: Check for signs of wear or damage in belts and hoses, replacing them as needed to prevent unexpected failures.

- Battery Health: Monitor the condition of batteries to ensure they are charged and capable of starting the generators when required.

- Air Filter Maintenance: Clean or replace air filters regularly to maintain efficient combustion and prevent engine damage from dust and debris.

- Cooling System Care: Inspect the cooling system for leaks or blockages, ensuring that the generators operate within the recommended temperature range.

- Fuel System Inspection: Regularly check the fuel system for leaks and contaminants, and address any issues promptly to prevent fuel-related problems.

- Exhaust System Check: Inspect the exhaust system for leaks or damage to prevent hazardous fumes from escaping and ensure proper engine performance.

- Controller Calibration: Verify the accuracy of the generator controllers and calibrate them as needed to ensure precise synchronization and load sharing.

- Emergency Shutdown Test: Periodically test the emergency shutdown system to confirm its functionality in case of any critical issues.

- Documentation: Maintain detailed maintenance records for each generator, documenting inspections, repairs, and replacements to track performance trends and aid in future troubleshooting.

Parallel Generators Safety Tips

When using parallel generators to increase power output, it’s crucial to prioritize safety. Follow these tips to ensure a secure and efficient setup.

- Same Model and Rating: Always connect generators of the same model and rating in parallel to avoid voltage and frequency mismatches, preventing potential damage to connected devices.

- Synchronization: Synchronize the generators before connecting them. This ensures that both generators produce power in harmony, minimizing the risk of electrical imbalances and damage to sensitive equipment.

- Matched Loads: Connect similar electrical loads to each generator to maintain a balanced distribution of power. This prevents overloading of one generator while the other remains underutilized.

- Proper Grounding: Ensure proper grounding of both generators to prevent electrical shocks and create a safe pathway for fault currents. This is vital for protecting equipment and ensuring operator safety.

- Break Before Make: Use a break-before-make switch or interlocking system when connecting or disconnecting generators. This prevents the risk of short circuits during the transition, reducing the chance of electrical faults.

- Monitoring Instruments: Install and regularly check monitoring instruments for each generator, including voltage, frequency, and current meters. This helps in identifying any irregularities promptly and taking corrective measures.

- Qualified Personnel: Only allow qualified personnel to operate and maintain parallel generator systems. Adequate training ensures they understand the risks and can respond effectively to any issues that may arise.

- Emergency Shutdown: Implement an emergency shutdown procedure to quickly disconnect generators in case of any abnormalities. This helps prevent further damage and ensures the safety of both equipment and personnel.

Remember, adhering to these safety tips is essential to prevent equipment damage, electrical hazards, and to maintain a reliable power supply in parallel generator setups.

Conclusion

In conclusion, the idea of linking two portable generators together can provide a valuable solution for increased power needs. However, it’s crucial to emphasize that this should be done with caution and following recommended practices. Always prioritize safety and consult your generator’s manual for specific guidance.

Can You Hook 2 Portable Generators Together is not only a question of technical possibility but also one of responsible power management. By understanding the process and taking proper precautions, you can ensure a reliable and secure power supply whenever the need arises.

References

- An electromagnetic, vibration-powered generator for intelligent sensor systems

- Electric generators and motors: An overview

- Analysis of a micro-electric generator for microsystems

- Linear electric actuators and generators

Frequently Asked Questions

Can I Connect More Than Two Portable Generators Together?

Connecting portable generators in parallel allows for increased power output and flexibility. Multiple generators can be connected to provide more power, ensuring a reliable power source. This setup has several benefits, such as increased capacity and redundancy in case of failure.

Is It Possible to Connect Generators of Different Wattage or Brand?

Connecting generators of different sizes or brands is possible, but it is important to consider the compatibility of their electrical outputs and the overall load distribution. Additionally, variations in noise levels should be taken into account for a harmonious operation.

Can I Connect Generators of Different Fuel Types (E.G., Gasoline and Propane)?

Connecting generators of different fuel types, such as gasoline and propane, can be feasible but requires careful consideration. While it may be possible, it is crucial to ensure safety and efficiency by following manufacturer guidelines and consulting a professional.

What Are the Limitations or Risks Associated With Connecting Multiple Generators?

The limitations of parallel generators and the risks associated with connecting them together should be considered. These include potential overload, improper synchronization, and electrical hazards. It is crucial to follow manufacturer guidelines to ensure safe and efficient operation.

Can I Connect Portable Generators With Different Output Voltage Levels?

When it comes to power compatibility, connecting portable generators with different voltage levels can pose risks. Wiring considerations are crucial as they determine the electrical requirements for safely connecting multiple generators.

What are the things to be considered while installing two generators parallelly?

When connecting generators in parallel or synchronizing with the utility, it’s crucial to ensure matched frequency, correct phase rotation, and phase voltages within the specified range.

Can generators be connected in series?

While not a direct connection, it is indeed possible with the use of synchronization devices. These devices facilitate the combination of output from each generator to work together seamlessly.

Can you parallel two non-inverter generators?

Absolutely, numerous gas-powered and rotating generators can be synchronized for simultaneous operation when connected.