Embarking on your outdoor adventure often requires reliable power sources, and the question echoing through the camping community is, Can You Run Two Portable Generators in Parallel? Picture this: you’re surrounded by nature’s beauty, but your energy needs demand a bit more. In the quest for seamless power, enthusiasts are curious about the possibilities of coupling portable generators.

As we dive into the world of parallel generator connections, join us on a journey where electricity meets the great outdoors. Discover the potential, the buzz, and the whisper of a solution that harmonizes power with the rhythm of your exploration.

Jump to a Specific Section

- 1 TLDR

- 2 What is a Portable Generator and How Does it Work?

- 3 What is Paralleling of Generators?

- 4 Why Do You Need to Parallel Generators?

- 5 Can You Run Two Portable Generators in Parallel?

- 6 How to Run Two Portable Generators in Parallel?

- 7 Factors to Consider before Paralleling Two Portable Generators

- 8 How Many Portable Generators can You Run in Parallel?

- 9 Can You Parallel Two Different Inverter Generators?

- 10 What are the Advantages of Running Two Generators in Parallel?

- 11 Is it Safe to Parallel Two Generators?

- 12 Tips for Running Portable Generators in Parallel

- 13 Conclusion

- 14 References

- 15 Frequently Asked Questions

- 15.1 Are There Any Additional Maintenance Requirements When Running Two Portable Generators in Parallel?

- 15.2 Can I Use Different Brands or Models of Portable Generators for Parallel Operation?

- 15.3 What Are the Potential Risks or Hazards Associated With Running Two Portable Generators in Parallel?

- 15.4 Is It Possible to Connect Multiple Types of Appliances or Equipment to the Parallel Generator Setup?

- 15.5 How Does Running Two Portable Generators in Parallel Affect the Overall Lifespan of the Generators?

- 15.6 What are the requirements for connecting generators in parallel?

- 15.7 Are generator parallel kits universal?

- 15.8 Can I use 2 generators to make 220 volts?

TLDR

- Running two portable generators in parallel can increase power output and improve fuel efficiency.

- Parallel operation allows for load distribution and automatic load balancing, resulting in more reliable and stable power generation.

- Synchronizing the generators ensures power compatibility and can provide redundancy in case of generator failure or maintenance.

- It is important to consider safety precautions such as proper grounding, load balancing, and regular maintenance when running generators in parallel.

What is a Portable Generator and How Does it Work?

Portable generators are invaluable power sources, offering flexibility and convenience during times of electrical outage or in remote locations where access to the grid is limited.

A portable generator operates on the principle of electromagnetic induction. Its core components include a fuel-powered engine, an alternator, and a control panel. The engine, often running on gasoline or propane, provides the necessary mechanical energy. This energy is then converted into electricity through the alternator, which contains a rotating magnetic field and a stationary coil.

- Fuel Conversion: The combustion of fuel in the engine produces a rotational force that drives the alternator. This rotation induces a magnetic field in the coil, generating an alternating current (AC). To make this power usable in homes and businesses, the generator further converts the AC into direct current (DC) through a built-in inverter.

- Control Panel and Voltage Regulation: Portable generators are equipped with a control panel that allows users to manage various aspects of power production. Users can monitor voltage, control output, and even find specialized outlets for different devices. Voltage regulation is crucial, ensuring that the power generated is consistent and safe for sensitive electronics.

- Automatic Voltage Regulators (AVR): To maintain stability, high-quality portable generators are often equipped with Automatic Voltage Regulators. AVR systems adjust the voltage output to keep it within a safe range, preventing electrical fluctuations that could damage connected devices.

In summary, a portable generator is a versatile power solution, relying on the principles of electromagnetic induction to convert mechanical energy into electrical power. Understanding its components, fuel conversion process, control panel features, and voltage regulation is essential for utilizing these generators effectively in various situations.

What is Paralleling of Generators?

Paralleling of Generators is a critical aspect of power generation systems, allowing multiple generators to operate together seamlessly. Paralleling refers to the connection of two or more generators to a common bus, creating a unified power source. This practice ensures a reliable and efficient power supply by distributing the electrical load among multiple generators. The primary goal of paralleling generators is to enhance overall system capacity, improve reliability, and enable flexibility in managing varying power demands.

The process involves synchronizing the frequency, voltage, and phase of each generator before connecting them to the shared bus. This synchronization is crucial to prevent issues like voltage differences and frequency variations, which can disrupt the stability of the power system. Synchronizing devices play a pivotal role in achieving this coordination, ensuring that the generators operate in harmony.

To illustrate, consider a scenario where a facility requires a variable amount of electricity throughout the day. By paralleling generators, the system can efficiently match the power demand at any given time, optimizing fuel consumption and minimizing wear and tear on individual units. This adaptability is particularly valuable in industries with dynamic energy needs.

Thus, paralleling generators is a sophisticated yet crucial technique in power generation, offering enhanced reliability, scalability, and operational efficiency. Proper synchronization and monitoring ensure that these generators function seamlessly as a unified power source, contributing to the overall stability of the electrical grid.

Why Do You Need to Parallel Generators?

One primary reason for opting to parallel generators is enhanced redundancy. By distributing the load across multiple units, the risk of a single point of failure is significantly reduced. This approach ensures a continuous power supply, even if one generator experiences issues or requires maintenance.

Moreover, parallel generators offer scalability. As the power demand grows, additional generators can be seamlessly integrated, preventing the need for a single, larger generator that might be both costly and less flexible. This scalability is especially beneficial in dynamic environments where power requirements may vary.

Additionally, parallel operation facilitates improved fuel efficiency. Generators running at partial load tend to be less fuel-efficient. By paralleling generators, it becomes possible to match the load more closely to the generators’ rated capacity, optimizing fuel consumption and reducing operational costs.

In practical terms, envision a scenario where a facility experiences a sudden surge in power demand due to increased operations. Parallel generators allow for a swift response by seamlessly distributing the additional load among the connected units, preventing disruptions and ensuring a continuous and reliable power supply.

Can You Run Two Portable Generators in Parallel?

Yes, you can run two portable generators in parallel. Some portable generators are designed with the capability to be connected in parallel, allowing you to effectively double your power output.

Before attempting this, it’s crucial to check the specifications of your generators. Look for terms like parallel capability or parallel operation in the user manual or product description. Generators equipped with this feature usually have specialized outlets or ports for parallel connections. The primary advantage of running generators in parallel is the increased power capacity, enabling you to handle larger loads or more appliances simultaneously.

However, it’s essential to be cautious and follow the manufacturer’s guidelines precisely. Connecting generators improperly can lead to electrical issues or damage the equipment. Additionally, ensure that the generators have similar power ratings and types to prevent imbalances.

In summary, running two portable generators in parallel is feasible if your generators support this feature. Always refer to the manufacturer’s instructions to ensure a safe and effective parallel operation, and consider consulting a professional if you have any doubts about the compatibility or setup.

How to Run Two Portable Generators in Parallel?

Running two portable generators in parallel can significantly enhance power output for increased efficiency. This setup is particularly useful when you require more power than a single generator can provide. Below are step-by-step instructions on how to run two portable generators in parallel.

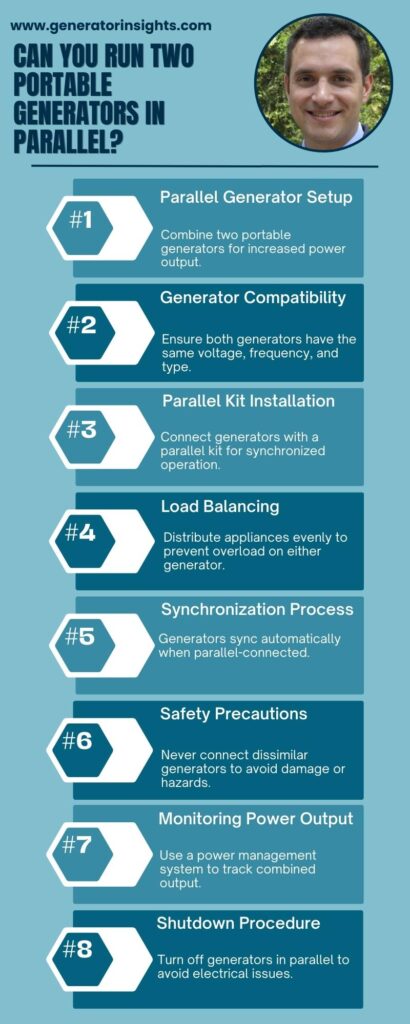

- Choose Compatible Generators: Ensure that both generators are compatible for parallel operation. Check the user manuals or labels on the generators for information on parallel capabilities.

- Verify Parallel Kit Compatibility: Confirm that you have a parallel kit designed for your specific generator models. A parallel kit typically includes the necessary cables and connectors.

- Turn Off Generators: Before connecting anything, turn off both generators and unplug any loads. Safety is paramount when dealing with electricity.

- Locate Parallel Outlets: Identify the parallel outlets on each generator. These are usually labeled and may be covered with protective caps.

- Connect Parallel Cables: Use the parallel kit to connect the generators. Attach the cables to the parallel outlets on both generators, ensuring a secure and snug connection.

- Ground the Generators: Ground both generators as per the manufacturer’s instructions. This step is crucial for safety and helps prevent electrical hazards.

- Start the Generators: Start both generators following the proper starting procedures outlined in the user manuals. Allow them to run for a few minutes to stabilize.

- Adjust Load Distribution: Monitor the power distribution between the generators. Some models have features that allow you to adjust the load-sharing ratio to optimize performance.

- Connect Loads: Once the generators are running smoothly in parallel, you can begin connecting your loads. Be mindful of the total power capacity to avoid overloading the system.

- Monitor and Maintain: Regularly monitor the generators and maintain them according to the manufacturer’s recommendations. This includes checking oil levels, fuel, and overall condition.

For instance, if you have two 2000-watt generators, running them in parallel effectively provides a 4000-watt power source. This flexibility is especially handy for powering larger appliances or tools during outdoor activities or in case of power outages.

Remember, always refer to the user manuals of your specific generators for accurate information and safety guidelines.

Factors to Consider before Paralleling Two Portable Generators

When contemplating the parallel operation of two portable generators, a meticulous examination of critical factors is paramount to ensure a robust and effective power setup. Before embarking on this endeavor, it’s essential to assess the following key factors.

1. Generator Compatibility

Before proceeding, reiterate the importance of verifying generator compatibility. The units must not only match in voltage, frequency, and phase but should also ensure the production of an adequate sine wave. A consistent and clean sine wave output is crucial for the safe and reliable operation of sensitive electronic devices.

2. Synchronization Capability

Synchronization is critical when paralleling generators. It ensures that the output voltage and frequency of each generator are precisely aligned before connecting them. Using generators without synchronization capability can result in power fluctuations, damaging connected devices and appliances. Opt for generators with built-in synchronization features or invest in external synchronization equipment.

3. Waveform

A significant consideration in paralleling generators is the quality of the waveform they produce. The generators must generate a stable sine wave to avoid electrical noise and harmonics that could harm connected equipment. Ensure that both generators are capable of producing a clean and undistorted sine wave under various load conditions.

4. Phase Sequence

Understanding the phase sequence is crucial to prevent phase conflicts when paralleling generators. The order in which voltage peaks are reached on the sine wave must match for synchronized operation. Consistent phase sequence ensures a smooth and harmonious power supply, reducing the risk of electrical issues and equipment damage.

4. Frequency Synchronization

In addition to ensuring compatible frequencies, delve into the specifics of frequency synchronization. Generators must operate at the same frequency to avoid instability and potential damage to connected loads. Accurate frequency synchronization is fundamental for maintaining a reliable and constant power supply in a parallel configuration.

5. Load Sharing Mechanism

Reiterate the importance of an efficient load-sharing mechanism in the context of waveform and frequency. A well-designed load-sharing system should consider not only the overall load but also the dynamic changes in frequency and waveform to ensure balanced power distribution among paralleled generators.

6. Control System Complexity

Consider the complexity of the control system required for paralleling generators. Advanced control systems provide automation and ease of operation, simplifying the parallel connection process. Investing in generators with user-friendly control interfaces and comprehensive monitoring capabilities can enhance overall system performance.

7. Fuel Compatibility and Consumption

Examine the fuel compatibility of the generators, ensuring they use the same type of fuel. Additionally, assess the fuel consumption rates of each unit when operating in parallel. Understanding fuel efficiency is crucial for managing costs and optimizing the runtime of the power system.

8. Maintenance and Serviceability

Evaluate the maintenance requirements and serviceability of the generators. Accessibility for routine maintenance tasks and ease of troubleshooting are essential aspects to consider. Opt for generators with clear maintenance instructions and readily available spare parts to minimize downtime.

Thus, before parallelizing two portable generators, a thorough consideration of these factors ensures a reliable and efficient power solution. By focusing on compatibility, synchronization, load sharing, control system complexity, fuel considerations, and maintenance aspects, you can create a robust parallel generator system tailored to your specific needs.

How Many Portable Generators can You Run in Parallel?

The number of generators you can run in parallel depends on the specific model and its design. Manufacturer guidelines play a pivotal role, outlining the maximum number of generators that can be safely connected. Typically, the majority of portable generators on the market support parallel operation of two generators. It’s essential to adhere to these guidelines to prevent overloading and ensure optimal performance.

Consider the combined wattage capacity when running generators in parallel; this sum should not exceed the recommended limits.

For instance, if you have two generators with a capacity of 3000 watts each, the combined output when running in parallel should not surpass the specified limit, ensuring a seamless and efficient power supply for your needs. Always consult the user manual and follow manufacturer recommendations for a safe and effective parallel generator operation.

Can You Parallel Two Different Inverter Generators?

Parallel operation is indeed a feasible option, but it comes with certain considerations. Inverter generators, known for their quiet operation and clean power output, can be parallel-connected to increase the overall power capacity. However, it is crucial to note that this is generally recommended for generators of the same make and model to ensure seamless synchronization.

Attempting to parallel generators from different manufacturers or even distinct models within the same brand might pose challenges. Each generator, despite being labeled as an inverter type, can have variations in internal electronics and control systems. These differences may lead to synchronization issues, impacting the stability and reliability of the combined power output. The frequency, voltage, and waveform consistency are essential factors that must align for successful parallel operation.

Moreover, parallel connection kits offered by manufacturers are typically designed for specific generator models. Attempting to parallel two different generators may void warranties and compromise the safety mechanisms integrated into the units. It’s crucial to refer to the product manuals and guidelines provided by the manufacturers to ensure a compatible and secure parallel setup.

In summary, while the concept of paralleling inverter generators holds potential advantages in boosting power output, it’s essential to prioritize compatibility and adhere to manufacturer recommendations. Always consult the user manuals, seek professional advice if needed, and err on the side of caution to ensure a reliable and safe power solution.

What are the Advantages of Running Two Generators in Parallel?

The advantages of adopting parallel generator setup are numerous, offering enhanced efficiency and reliability in power generation.

- Increased Power Output: By running generators in parallel, the combined power output is significantly higher than that of a single unit. This scalability proves invaluable in situations demanding a robust and adaptable power supply.

- Redundancy and Reliability: Parallel operation provides a layer of redundancy. In the event of a failure in one generator, the other can seamlessly compensate, ensuring a continuous power supply. This redundancy enhances the overall reliability of the power system.

- Fuel Efficiency: Running generators concurrently at partial loads rather than one at full capacity can lead to improved fuel efficiency. This is particularly advantageous during periods of lower power demand, contributing to cost savings and environmental sustainability.

- Load Sharing: Parallel generators can dynamically share the load based on the power demand. This load-sharing capability prevents overloading of a single generator and ensures a balanced distribution of power, optimizing the performance of each unit.

- Flexibility in Maintenance: Operating generators in parallel allows for more flexibility in maintenance schedules. With one unit taken offline for maintenance, the other can continue to supply power, minimizing disruptions in critical operations.

- Voltage Stability: Parallel operation facilitates better voltage regulation, ensuring a stable and consistent voltage supply. This is crucial for sensitive electronic equipment and systems that require a precise voltage level.

In summary, the advantages of running two generators in parallel are multifaceted, encompassing increased power output, enhanced reliability, fuel efficiency, load sharing, maintenance flexibility, and improved voltage stability. This approach proves particularly beneficial in applications where a robust and uninterrupted power supply is imperative.

Is it Safe to Parallel Two Generators?

Ensuring a safe parallel operation demands attention to several factors.

Firstly, compatibility between the generators is paramount. The generators should have matching voltage, frequency, and phase to prevent potential damage or malfunction. Mismatched parameters can lead to uneven power distribution and jeopardize connected devices.

Additionally, it’s imperative to employ a synchronization system when parallelizing generators. This system ensures that both generators are operating in harmony, minimizing the risk of electrical imbalances and ensuring a smooth power supply. Failure to synchronize can result in damaging electrical surges and compromise the stability of the entire system.

Moreover, having a clear understanding of each generator’s load-sharing capability is essential. Generators should be equipped with the ability to distribute loads proportionally to avoid overloading one unit while the other operates at a lower capacity.

Tips for Running Portable Generators in Parallel

When it comes to maximizing power output and efficiency, running portable generators in parallel is a smart strategy. Here are some essential tips to ensure a seamless parallel operation:

- Select Compatible Generators: Ensure that the generators are of the same make and model. Mismatched units may lead to uneven power distribution and potential damage.

- Matched Power Output: Verify that both generators have similar power outputs. This prevents one generator from overworking and promotes a balanced load sharing.

- Synchronize Frequencies: It’s crucial to synchronize the frequencies of the generators. This ensures that they are generating power in phase, preventing disruptions or power imbalances.

- Use Parallel Kits: Invest in parallel operation kits designed for your generators. These kits include the necessary cables and connectors to facilitate safe and efficient parallel connections.

- Mind Load Distribution: Be mindful of the distribution of electrical loads across both generators. Evenly distribute the load to prevent overloading of one generator while the other remains underutilized.

- Monitor Voltage Levels: Regularly check and monitor voltage levels to avoid any fluctuations. Maintaining a stable voltage is essential for the proper functioning of connected appliances and devices.

- Fuel Compatibility: Ensure that both generators use the same type of fuel. Mixing fuel types can lead to engine damage and affect the overall performance of the parallel setup.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s guidelines for parallel operation. Each generator model may have specific instructions that need to be followed for safe and effective parallel usage.

Implementing these tips will not only enhance the efficiency of your parallel generator setup but also extend the life of your equipment.

Conclusion

In conclusion, the answer to the question, Can You Run Two Portable Generators in Parallel is a resounding yes. This ingenious method empowers you to scale up your power capacity, providing flexibility and reliability in times of need. By synchronizing the output of two generators, you create a formidable power source capable of handling even the most demanding electrical loads. Whether for emergency backup or powering outdoor events, parallel operation is a game-changing technique. As you embark on this endeavor, remember to prioritize safety and follow manufacturer guidelines. With this knowledge, you’re poised to unlock a new level of power resilience and versatility.

References

- An electromagnetic, vibration-powered generator for intelligent sensor systems

- Electric generators and motors: An overview

- Analysis of a micro-electric generator for microsystems

- Linear electric actuators and generators

Frequently Asked Questions

Are There Any Additional Maintenance Requirements When Running Two Portable Generators in Parallel?

When running two portable generators in parallel, there are additional maintenance requirements to consider. Regular inspection of both generators, such as checking oil levels and filters, is necessary. Troubleshooting tips may include identifying any issues with the parallel connection or load balancing.

Can I Use Different Brands or Models of Portable Generators for Parallel Operation?

When running two portable generators in parallel, it is generally recommended to use the same brand and model for optimal compatibility and performance. Using different brands may pose challenges and reduce the advantages of parallel operation.

What Are the Potential Risks or Hazards Associated With Running Two Portable Generators in Parallel?

Running two portable generators in parallel can pose potential risks and hazards. These may include electrical overload, improper synchronization, fuel mixing issues, and increased noise and emissions. It is important to follow manufacturer guidelines and take necessary precautions to mitigate these risks.

Is It Possible to Connect Multiple Types of Appliances or Equipment to the Parallel Generator Setup?

Yes, it is possible to connect multiple appliances or equipment to a parallel generator setup. Different types of appliances and equipment can be connected, allowing for simultaneous operation and increased power output.

How Does Running Two Portable Generators in Parallel Affect the Overall Lifespan of the Generators?

Running two portable generators in parallel does not significantly affect the overall lifespan of the generators. However, it can increase the power output compared to using a single generator, while fuel efficiency may be affected, with two generators consuming more fuel.

What are the requirements for connecting generators in parallel?

To enable parallel operation of two or more generators, it’s crucial that they produce a sufficient sine wave and maintain the same order of voltage peaks on the waveform, ensuring matching phase sequences.

Are generator parallel kits universal?

Generator parallel kits, deemed universal, are compatible with most generator brands (both standard and inverter types) featuring ROUND parallel ports. The kit’s LOW PROFILE PLUG, with a 90° Degree Angle, minimizes protrusion, reducing the risk of damage and breakage, and it functions without requiring a companion generator.

Can I use 2 generators to make 220 volts?

The synchronization required for two generators to jointly produce 220 volts is challenging with home generators. Instead, a more feasible approach involves using a 110 to 220 volt step-up transformer for achieving the desired voltage without synchronization concerns.