Embarking on the journey of understanding how to break in a portable generator can be both enlightening and empowering. Picture this: your trusty generator standing by, ready to be a beacon of reliability in times of need. But, like any sturdy companion, it needs a thoughtful initiation.

In this guide, we’ll unravel the secrets of breaking in your portable power ally, ensuring it becomes a stalwart source of energy when you need it most. Join us on this adventure, as we explore the intricacies of generator care and witness firsthand how a little attention at the start can yield a powerhouse performance down the road.

Jump to a Specific Section

- 1 Key Takeaways

- 2 How to Break in a Portable Generator?

- 3 What Should You Use as Load when Breaking in a Generator?

- 4 How Long Does it Take to Break in a Generator?

- 5 Conclusion

- 6 References

- 7 Frequently Asked Questions

- 7.1 What Type of Fuel Is Best for a Portable Generator?

- 7.2 How Often Should I Check the Oil Level?

- 7.3 What Safety Measures Should I Take When Using a Generator?

- 7.4 How Do I Know When It’s Time to Replace the Generator?

- 7.5 Do I Need to Use a Surge Protector With a Portable Generator?

- 7.6 Do you have to break in a portable generator?

- 7.7 How long should you run a generator before giving it a break?

- 7.8 Do I need to break in a refurbished generator?

Key Takeaways

- Read the manufacturer’s instructions and familiarize yourself with the generator’s features

- Follow recommended refueling intervals and cold start processes

- Regularly check and maintain oil and fuel levels

- Perform necessary maintenance tasks as outlined in the manufacturer’s instructions

How to Break in a Portable Generator?

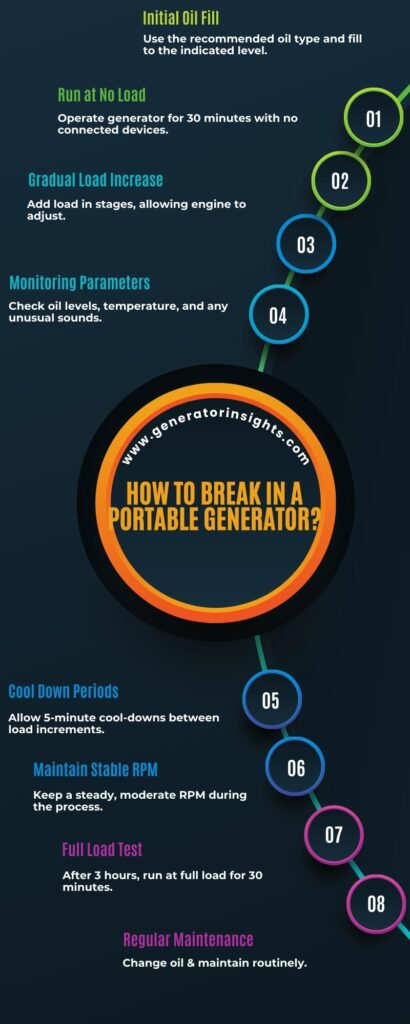

Breaking in a portable generator is a crucial step to ensure its longevity and optimal performance. Here’s how to do it:

- Read the Manual: Start by thoroughly reading the manufacturer’s manual. Different generators may have specific break-in procedures, which could vary based on their make and model.

- Initial Oil Fill: Ensure the generator has the correct amount and type of oil as recommended by the manufacturer. This initial oil fill is critical for proper lubrication during the break-in period.

- Run at No Load: Start the generator and let it run at no load for the first 30 minutes. This allows the engine components to settle in without the stress of powering any appliances.

- Gradually Add Load: After the initial 30 minutes, begin to add load in stages. Start with light loads and gradually increase over the next few hours.

- Avoid Overloading: During the break-in period, avoid overloading the generator. This could lead to premature wear and potential damage to the engine.

- Monitor Vital Signs: Keep an eye on the generator’s vital signs like oil pressure and temperature. Any unusual readings should be addressed immediately.

- Allow for Cool Down: After a few hours of operation, let the generator cool down for at least 15-20 minutes.

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule. This includes oil changes, air filter checks, and spark plug inspections.

Breaking in a generator is akin to a ‘shakedown cruise’ for a new vehicle. It allows the engine’s components to settle and adapt to working together. Starting with no load reduces the initial stress on the engine, while gradually adding load ensures a smooth transition to full operation.

Avoiding overloading is crucial to prevent excessive strain on the engine during this critical period. Monitoring vital signs ensures that any issues are addressed promptly.

Following the manufacturer’s maintenance schedule is essential for the long-term health and performance of the generator. Regular oil changes, air filter replacements, and spark plug inspections are vital for sustained functionality.

Now let’s discuss how to break in a portable generator in detail.

Choose the Right Generator

When selecting a portable generator, it is important to consider the intended use and power requirements. Factors such as fuel type, size of the generator, noise level, budget constraints, and safety features should also be taken into account when making your selection.

For example, if you are looking for a generator that can power essential home appliances during an emergency situation or natural disaster, you will want to choose one that runs on gasoline or diesel fuel. Additionally, if noise levels are a concern in your area or neighborhood then it would be wise to select a model with lower decibel ratings.

Another factor to consider is portability; some generators weigh more than others and may require special transportation equipment depending on where they need to go. In addition to this, those operating on different fuel sources will have different price points depending on their efficiency and capacity.

Furthermore, budget-conscious buyers should make sure that the generator they choose includes all necessary safety features such as overload protection and automatic shutoff capabilities.

Overall, when choosing a portable generator it is important to take into account factors such as fuel type, noise level, weight considerations and budget constraints before making your final selection in order to ensure that you get the most out of your purchase while still belonging with the community standards of safety and performance.

Prepare Generator for Use

Prior to use, certain steps must be taken in order to ensure the safety and proper functioning of a portable generator. The fuel type should be checked, ensuring that it is suitable for the particular model. Once the correct fuel type has been established, it is important to fill the tank with fresh gasoline and place a few drops of oil into the cylinder. In addition, storage tips must be noted in order to maintain longevity of use.

| Activity | Resource | Time |

|---|---|---|

| Check Fuel Type | User Manual | 10 Minutes |

| Fill Tank with Gasoline | Gasoline Station | 5 Minutes |

| Place Drops of Oil Into Cylinder | Oil Container | 1 Minute |

It is also essential to check all connections for leaks prior to use, as well as operate the device on flat ground outside in an open area that allows for ventilation. Furthermore, it is recommended that wearing protective gear such as gloves and safety glasses when handling any flammable liquid or fuel related products. Finally, always make sure that all cords are properly connected and follow all safety precautions listed within your user manual before using your portable generator.

Set Up the Generator

Properly setting up a generator is essential for safety and efficiency. Before beginning, ensure that the area selected is free from any combustible materials. Additionally, check to make sure that the generator has plenty of ventilation and is placed in an area where it will not be exposed to excess moisture or dampness.

Comply with all local regulations regarding fuel storage and generator placement. Secure the generator safely to prevent it from vibrating excessively during operation. Make sure there are no objects blocking the air flow around the unit.

When preparing to set up your portable generator, consult your user manual for specific instructions on installation and safety protocols. Follow all recommended guidelines when connecting extension cords or other electrical devices into outlets on your generator. In addition, inspect all connections for looseness or damage prior to powering up the device. Use only approved cables designed specifically for use with generators, as improper wiring can cause serious injury or death due to electric shock.

Lastly, always wear protective gear such as gloves and eye protection when handling fuel and operating your portable generator.

Prim the Generator

When it comes to optimizing your generator’s performance, priming the generator during breaking in is a crucial step in ensuring its smooth operation. During the initial stages of using a generator, it’s essential to follow specific procedures to enhance its efficiency and longevity.

Priming the generator involves the process of preparing it for optimal functionality. This typically includes ensuring that all components are adequately lubricated and that the generator is ready to handle the demands it will face during regular operation. Proper priming helps prevent wear and tear, reduces the risk of malfunctions, and contributes to a more reliable performance over time.

One key aspect of priming is to pay attention to the fuel system. Make sure that the fuel lines are properly filled and that any air within the system is purged. This is crucial for the generator to start and operate smoothly. Air bubbles in the fuel lines can lead to interruptions in fuel delivery, potentially causing the generator to stall or operate inefficiently.

Additionally, during the breaking-in period, pay attention to the lubrication of moving parts. Adequate lubrication is vital for reducing friction and preventing premature wear. Regular checks and adjustments to the oil levels ensure that the generator’s engine functions optimally, promoting a longer lifespan for the equipment.

In summary, priming the generator during breaking in is a fundamental step in ensuring its reliability and longevity. By focusing on proper fuel system preparation and lubrication, you contribute to the overall efficiency of the generator, reducing the likelihood of issues during operation. Remember, a well-primed generator is a more dependable power source in the long run.

Do a Load Run

During a load run, the generator is subjected to varying levels of electrical demand to assess its ability to handle different loads. This process is essential for detecting weaknesses, malfunctions, or potential points of failure within the generator system. It goes beyond routine checks and offers a more comprehensive evaluation of the generator’s overall health.

One key aspect to monitor during a load run is how the generator responds to increased loads. Observing the stability and efficiency of the generator under stress conditions provides valuable insights into its capacity and performance thresholds. This proactive approach aids in preventing unexpected breakdowns during critical operations, which can be particularly detrimental in various industries.

Regular load runs contribute to predictive maintenance strategies, allowing for timely interventions and reducing the likelihood of unplanned downtime. This proactive approach not only extends the lifespan of the generator but also minimizes the risk of costly repairs or replacements.

Thus, a meticulous load run of the generator is an indispensable practice for any facility reliant on a stable power supply. It serves as a preemptive measure, allowing for the identification and resolution of potential issues, thereby ensuring the generator’s resilience in the face of varying electrical demands.

What Should You Use as Load when Breaking in a Generator?

When breaking in a generator, choosing the right load is crucial to ensure optimal performance and longevity. Load refers to the amount of power the generator needs to produce to operate efficiently. Selecting an appropriate load during the break-in period helps the generator’s components settle and function optimally.

During the initial hours of operation, it is recommended to use a load that is at least 30-50% of the generator’s maximum capacity. This moderate load allows the engine and other internal components to experience a gradual and controlled stress, aiding in the proper seating of piston rings and other critical parts. Avoid running the generator with no load or at very light loads during this break-in period, as it may lead to glazing of cylinder walls and hinder the break-in process.

Varying the load is also beneficial during the break-in phase. Introducing fluctuations in the load helps different engine components adjust to varying stress levels. This promotes a more uniform break-in and contributes to the overall durability of the generator.

It’s important to consult the generator’s manual for specific guidelines on load requirements during the break-in period. Manufacturers often provide detailed instructions to ensure the optimal break-in conditions for their generators.

In summary, selecting an appropriate load, maintaining moderate stress levels, and varying the load during the break-in period are key considerations for ensuring the long-term reliability and performance of your generator.

How Long Does it Take to Break in a Generator?

Generators play a crucial role in providing backup power during emergencies or in areas with unreliable electricity sources. However, many users wonder about the break-in period for a new generator and how long it takes to ensure optimal performance.

The break-in period for a generator typically ranges from 50 to 100 hours of operation. During this initial phase, it’s essential to follow the manufacturer’s guidelines to allow the various components, such as the engine and alternator, to settle and function smoothly. This process is crucial for the longevity and efficiency of the generator.

One key aspect during the break-in period is to vary the load on the generator. Avoid keeping it at a constant high load for an extended period. Instead, alternate between light and moderate loads to help distribute the stress evenly across the engine and components.

Regular maintenance is also crucial during this period. Check the oil levels, air filters, and other components as recommended by the manufacturer. This ensures that the generator functions optimally and minimizes the risk of potential issues in the future.

In conclusion, investing time in properly breaking in a generator is a proactive step that pays off in the long run. It sets the stage for reliable performance and extends the lifespan of the equipment, providing you with a dependable power source when you need it most.

Conclusion

In conclusion, How to Break in a Portable Generator is the cornerstone of ensuring its longevity and dependable performance. By following the prescribed steps and allowing the generator to adapt gradually, you pave the way for a reliable power source in times of need. Remember, the initial moments are crucial for its overall lifespan.

Let this guide serve as your trusted companion, reminding you of the importance of a proper break-in process. With this foundation, your portable generator will stand ready to provide you with the power you require, whenever you need it.

References

- Linear electric actuators and generators

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

Frequently Asked Questions

What Type of Fuel Is Best for a Portable Generator?

Fuel selection for a portable generator is important, as it can affect its life expectancy. The best type of fuel to use is usually unleaded gasoline that has been stored in an airtight container with stabilizer additives and kept between 40-90 days. Additionally, following storage tips such as avoiding sunlight exposure and storing in a cool, dry place can help ensure the fuel remains viable.

How Often Should I Check the Oil Level?

Maintaining and changing oil regularly is important for the longevity of a portable generator. It should be checked before every use, and then changed at least twice a year to ensure optimal performance. Doing so will help ensure its reliability and efficient operation.

What Safety Measures Should I Take When Using a Generator?

To ensure safety when using a generator, consider protecting children and securing it in storage; for an enjoyable experience, take the time to gain knowledge of the product and its use. Ensure proper handling, use protective gear, and follow manufacturer instructions for secure operation.

How Do I Know When It’s Time to Replace the Generator?

It is important to regularly inspect the generator for signs of wear and tear. Look for fuel selection that might be inadequate or oil changes that haven’t been done. If any of these concerns are present, it may be time to replace the generator.

Do I Need to Use a Surge Protector With a Portable Generator?

When operating a portable generator, it is recommended to use a surge protector to ensure proper startup process and reduce noise levels. It can also be beneficial to consult an expert on the best protection for your particular generator model.

Do you have to break in a portable generator?

Yes, it’s essential to break in a portable generator for optimal lifespan. The initial hours of operation significantly influence its overall durability. So, before embarking on your next camping adventure or backyard activities, ensure to go through the break-in process.

How long should you run a generator before giving it a break?

Manufacturers advise running the generator continuously for a maximum of 500 hours. However, for portable generators, it’s recommended to operate them in shorter intervals, typically between six to 18 hours, depending on the specific model.

Do I need to break in a refurbished generator?

Yes, a Break-In period is recommended for both new and refurbished generators, particularly for re-manufactured engines. In the case of refurbished generators, it’s advisable to perform an early oil change around the 50-hour mark, instead of the usual 100-hour interval. This helps ensure the removal of any debris, corrosion, sand, etc., promoting better performance and longevity.