Embarking on the journey of ensuring your portable generator’s reliability is both empowering and essential. Whether you’re gearing up for a camping adventure or preparing for unforeseen power outages, knowing how to test a portable generator is your key to uninterrupted convenience.

In this guide, we’ll unravel the simplicity behind ensuring your generator’s peak performance, providing you with the confidence to face any situation. No longer will uncertainty linger when the lights go out—mastering the art of testing your portable generator ensures you’re always in control. Let’s dive into the world of assurance and preparedness.

Jump to a Specific Section

- 1 Core Insights

- 2 How to Test a Portable Generator?

- 3 Troubleshooting Common Portable Generator Issues

- 4 How to Repair a Portable Generator?

- 5 Portable Generator Maintenance Tips

- 6 Generator Safety Tips

- 7 Conclusion

- 8 References

- 9 Frequently Asked Questions

- 9.1 What Are the Most Common Safety Hazards Associated With Using a Portable Generator?

- 9.2 How Do I Properly Connect and Ground a Portable Generator to My Home’s Electrical System?

- 9.3 Can I Safely Use a Portable Generator Indoors or in a Closed Space?

- 9.4 Are There Any Specific Tools or Equipment Required for Regular Maintenance of a Portable Generator?

- 9.5 How Often Should I Service or Tune-Up My Portable Generator to Ensure Its Optimal Performance?

- 9.6 How do you test if a generator is working?

- 9.7 How do I know if my generator is bad?

- 9.8 How do you inspect a portable generator?

Core Insights

- Safety precautions should be followed, including wearing PPE and ensuring proper ventilation.

- Gathering necessary equipment such as a multimeter, fuel stabilizer, spark plug wrench, engine oil, and load bank tester.

- Regularly checking fuel and oil levels, as well as performing maintenance checks on the air filter and battery.

- Following proper starting techniques and troubleshooting techniques for starting issues, as well as testing power output and implementing shutting down procedures.

How to Test a Portable Generator?

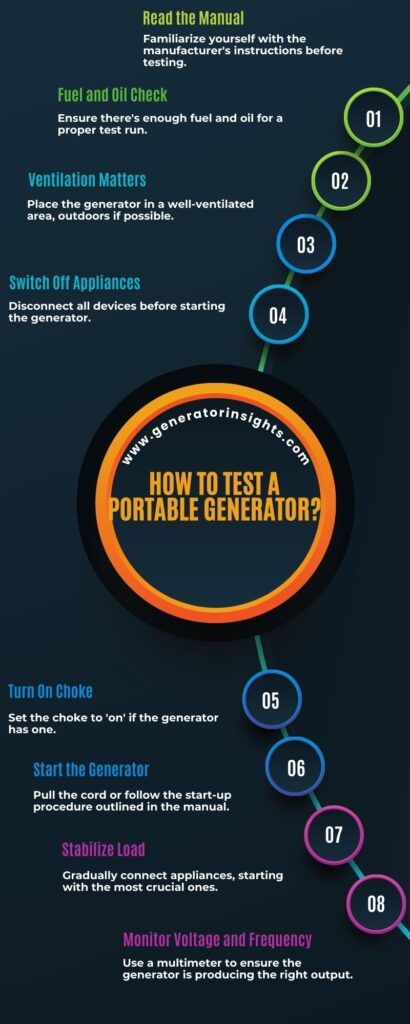

Testing a portable generator is crucial to ensure it’s in optimal working condition. Here’s a step-by-step guide on how to do it:

- Read the Manual: Begin by familiarizing yourself with the manufacturer’s instructions. This will give you specific guidelines for your particular generator model.

- Place the Generator: Set up the generator in a well-ventilated, outdoor area. Ensure it’s on a flat surface, away from combustible materials.

- Fuel and Oil Check: Confirm that there’s enough fuel and oil in the generator. Some models have an oil level sensor that prevents operation when oil is low.

- Switches and Choke: Turn off all the switches, set the choke to the ‘On’ position, and ensure the fuel valve is open.

- Start the Generator: Pull the starter cord or engage the electric start if your model has one. Allow the engine to run for a few minutes.

- Power a Load: Plug in a small, non-sensitive electronic device like a lamp. This will confirm that the generator is producing power.

- Check Voltage Output: Use a multimeter to measure the voltage output. For most household appliances, it should read between 110V and 120V.

- Test with Various Loads: Gradually add more appliances to the generator, monitoring the voltage. This simulates different levels of demand.

- Monitor Frequency: Use a frequency meter to check if the generator is providing power at the standard 60 Hz frequency.

- Idle Down: If your generator has an idle control feature, ensure it works by toggling it on and off.

- Turn Off Safely: Gradually disconnect all loads, then switch off the generator following the manufacturer’s instructions.

Remember, safety always comes first. If you encounter any issues during the testing process, refer to the manual or seek professional assistance. Regular testing and maintenance will keep your portable generator in peak condition for reliable use during emergencies or outdoor activities.

Now let’s discuss the whole process of testing a portable generator in detail.

Gather Necessary Equipment

In order to properly evaluate the functionality of a portable generator, it is necessary to assemble the required equipment. This ensures that the maintenance and safety measures are carried out effectively.

Here are five essential tools needed for testing a portable generator:

- Multimeter: A multimeter is used to measure voltage, current, and resistance in electrical circuits. It helps in determining if the generator is producing the correct amount of electricity.

- Fuel Stabilizer: Adding fuel stabilizer to the generator’s fuel tank prevents gasoline from deteriorating over time, ensuring optimal performance.

- Spark Plug Wrench: This tool is necessary for removing and inspecting the spark plug. A damaged or dirty spark plug can affect the generator’s ignition system.

- Engine Oil: Checking and maintaining proper oil levels in the engine is crucial for smooth operation. The owner’s manual will provide specific information regarding recommended oil type and capacity.

- Load Bank Tester: This device simulates an electrical load on the generator, allowing you to assess its ability to handle different power requirements.

By gathering these tools, individuals can perform routine maintenance on their portable generators with confidence.

The next section will delve into checking fuel and oil levels for optimal functioning of these systems.

Check Fuel and Oil Levels

When testing a generator, ensuring proper fuel and oil levels is crucial for optimal performance and longevity. Begin by inspecting the fuel level. Locate the fuel gauge on the generator and check whether it indicates a sufficient amount of fuel. Keep in mind that an inadequate fuel level can lead to interruptions in power generation.

Moving on to the oil levels, it’s essential to conduct this check when the generator is not running. Identify the oil dipstick, usually situated near the engine, and carefully pull it out. Wipe off any oil with a clean cloth and reinsert the dipstick fully. Withdraw it again to examine the oil level. The dipstick typically has markings indicating the optimal oil level. Ensure the oil level falls within the recommended range.

In cases where the oil level is below the specified range, it’s imperative to add the appropriate type and amount of oil. Refer to the generator’s manual for precise details on the oil specifications. Use a funnel to pour the oil gradually, preventing spills and ensuring accuracy. Recheck the oil level using the dipstick to confirm that it now aligns with the recommended range.

Regularly monitoring and maintaining proper fuel and oil levels not only ensures the generator’s functionality but also contributes to its longevity and reliability. As a preventive measure, establish a routine for these checks, especially before periods of extended use or during routine maintenance intervals.

Start the Generator

When it comes to testing a generator, starting the generator is a crucial step in ensuring its functionality. Properly initiating the generator is not only a fundamental part of the testing process but also a key aspect of guaranteeing its reliability during actual usage. In this section, we’ll delve into the steps involved in starting a generator as part of the testing procedure.

To commence the generator, begin by checking the fuel level. Ensure that there is an adequate supply of fuel for the generator to operate seamlessly. Next, inspect the oil level and quality. Adequate lubrication is vital for the generator’s engine to function optimally.

Now, move on to the battery inspection. A charged and properly functioning battery is essential for initiating the generator. Verify that the battery terminals are clean and securely connected. If needed, charge the battery before proceeding.

After confirming the fuel, oil, and battery status, locate the generator’s start switch or key. Turn the key to the “Start” position or engage the start switch. In some cases, generators may have a pull-start mechanism; follow the manufacturer’s instructions for this procedure.

It is worth mentioning that as the generator starts, pay close attention to the initial sounds and any warning lights. Unusual noises or indicator lights can indicate potential issues that need further investigation. Allow the generator a few moments to stabilize after startup.

Test Power Output

To evaluate the power output of a portable generator, it is crucial to employ a reliable method that accurately measures the electrical capacity. One commonly used method is load testing, which involves applying a known load to the generator and measuring its response. This allows for an assessment of the generator’s ability to deliver power under different conditions.

Load testing involves several steps:

- Determine the power capacity of the generator: Before conducting any tests, it is important to know the rated power capacity of the generator. This information can usually be found in the manufacturer’s specifications or user manual.

- Connect appropriate loads: Select loads that represent typical usage scenarios for your portable generator. These may include resistive loads like light bulbs or inductive loads like motors.

- Gradually increase load: Start with a small load and gradually increase it while monitoring voltage and frequency readings using a digital multimeter or dedicated testing equipment.

- Observe performance: Note how well the generator maintains steady voltage and frequency as load increases. Any significant fluctuations could indicate limitations in its power output capabilities.

- Record results: Keep detailed records of voltage, frequency, and any other relevant measurements during each stage of loading. This data will help assess whether the generator meets your power requirements consistently.

Shut Down the Generator

In addition to testing the power output of a portable generator, it is crucial to understand the shutting down procedures. When shutting down a portable generator, it is essential to follow specific procedures to prevent any damage or safety hazards. The table below outlines the recommended steps:

| Step | Procedure |

|---|---|

| 1 | Turn off all connected appliances and equipment. |

| 2 | Allow the generator to run without load for a few minutes to cool down. |

| 3 | Turn off the engine using the designated switch or key. |

| 4 | Close the fuel valve if available, preventing any leaks during storage. |

| 5 | Disconnect spark plug wire(s) to eliminate accidental starts. |

Troubleshooting Common Portable Generator Issues

Portable generators are essential for providing power in various situations. However, users may encounter issues that hinder their functionality. Understanding and troubleshooting these common problems is crucial for ensuring a reliable power source.

| Problem | Solution |

|---|---|

| 1. Starting Issues | If your generator fails to start, check the fuel level and ensure the ignition switch is on. |

| 2. No Power Output | Examine the circuit breakers and replace any blown fuses. Also, inspect the spark plug condition. |

| 3. Overheating | Ensure proper ventilation and check for dirt or debris obstructing the cooling system. |

| 4. Engine Stalling | Investigate the fuel filter and the air filter for clogs. Clean or replace them if necessary. |

| 5. Low Voltage Output | Adjust the engine speed to regulate voltage and troubleshoot the voltage regulator if needed. |

| 6. Fuel Leaks | Inspect the fuel lines and connections for leaks. Tighten or replace parts as required. |

| 7. Pull Cord Issues | Check the pull cord for any tangles or knots. Replace if damaged, and ensure proper winding. |

| 8. Carbon Buildup | Remove excessive carbon deposits on the spark plug and exhaust system to maintain optimal performance. |

How to Repair a Portable Generator?

Portable generators are indispensable in times of power outages, camping trips, or outdoor events. Ensuring your portable generator is in optimal condition is crucial for reliable performance. Let’s delve into a step-by-step guide on how to repair a portable generator in case it encounters issues.

Begin by conducting a thorough inspection of the generator. Check for any visible damage, loose wires, or components. Tighten any loose connections, and replace damaged parts if necessary. It’s essential to start with a clean slate to identify the root cause of the problem.

Inspect the fuel system, including the fuel tank, lines, and carburetor. Ensure there’s no debris or contamination that might be obstructing the fuel flow. Cleaning or replacing the fuel filter can often resolve issues related to fuel supply.

Next, focus on the ignition system. Check the spark plug for signs of wear or fouling. A worn-out spark plug can lead to starting issues or poor performance. Replace the spark plug if needed, and ensure the spark plug gap is within the manufacturer’s specifications.

Moving on, examine the air intake and exhaust system. A clogged air filter can hinder airflow and affect engine performance. Replace or clean the air filter regularly to maintain proper combustion. Additionally, inspect the exhaust system for any blockages or damage.

Take a closer look at the oil system. Ensure the oil level is adequate and the oil is clean. Change the oil at regular intervals as per the manufacturer’s recommendations. Low oil levels or dirty oil can lead to engine damage.

If your generator has an electric starter, check the battery’s condition. A weak or dead battery can prevent the generator from starting. Charge or replace the battery as needed to ensure a reliable start.

Lastly, run a test by starting the generator. Observe its performance and listen for any unusual sounds. If the issue persists, it may be necessary to consult the manufacturer’s manual for specific troubleshooting steps or seek professional assistance.

Regular maintenance and timely repairs are essential to keep your portable generator in top-notch condition, ensuring it’s ready to provide power when you need it most.

Portable Generator Maintenance Tips

In regions prone to power outages, ensuring portable generator maintenance is crucial for optimal performance. Neglecting upkeep can lead to malfunctions when you need power the most.

- Regular Oil Checks: Monitor oil levels consistently to guarantee the engine functions smoothly. Change oil every 50 hours of use or as recommended by the manufacturer.

- Fuel Freshness: Stale fuel can clog the carburetor. Add a fuel stabilizer and use fresh gasoline to prevent starting issues.

- Air Filter Inspection: Clean or replace the air filter every 25 hours of use to maintain proper airflow and prevent engine damage.

- Spark Plug Care: Examine and clean the spark plug regularly. Replace it if there’s significant wear to ensure efficient combustion.

- Battery Check: If your generator has a battery, inspect it for corrosion and ensure it’s charged. A functional battery is crucial for electric start models.

- Run the Generator Regularly: Even if not in use, run the generator for a short period every month to keep components lubricated and prevent fuel system issues.

- Cooling System Maintenance: Check the cooling system, ensuring that the radiator fins are clean and unobstructed for proper heat dissipation.

- Inspect for Leaks: Regularly check for fuel or oil leaks. Address any issues promptly to avoid damage to the generator and the surrounding environment.

- Store Properly: When not in use, store the generator in a dry and cool place. Use a cover to protect it from dust and debris.

- Read the Manual: Always refer to the manufacturer’s manual for specific maintenance instructions. Follow the recommended schedule for checks and replacements.

Remember, consistent and thorough maintenance of your portable generator ensures it’s ready to provide power when you need it most.

Generator Safety Tips

In any setting, generator safety is paramount to prevent accidents and ensure smooth operation. Here are crucial tips to keep in mind:

- Ventilation Matters: Always operate your generator in a well-ventilated area to prevent the buildup of harmful gases.

- Grounding is Key: Ensure proper grounding to minimize the risk of electrical shocks and ensure the generator’s stability.

- Regular Maintenance: Schedule routine checks for fuel, oil, and filters to maintain optimal performance and longevity.

- Distance from Structures: Place the generator at a safe distance from buildings to avoid carbon monoxide exposure and fire hazards.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s instructions for installation, usage, and maintenance to guarantee safety.

- Use Quality Fuel: Choose high-quality fuel to enhance efficiency and prevent clogs or damage to the generator.

- Emergency Kit Ready: Keep an emergency kit nearby, including fire extinguishers and first aid supplies, for immediate response.

- Secure Cords and Wires: Prevent tripping hazards by securing cords and wires, reducing the risk of accidents.

Understanding and implementing these generator safety tips will ensure a secure and efficient power supply in any situation.

Conclusion

In conclusion, knowing How to Test a Portable Generator is an invaluable skill for every responsible generator owner. Regular testing ensures that your backup power source is reliable and ready to serve when needed most. By following the steps outlined in this guide, you can have confidence in your generator’s performance.

Remember to conduct tests at regular intervals and address any issues promptly. Let this guide be your trusted companion in maintaining a seamless power supply for your home. With proper testing and maintenance, you can rest easy knowing that you’re prepared for any power outage that may come your way.

References

- Electrical generators for large wind turbine: Trends and challenges

- Bio-inspired water-driven electricity generators: From fundamental mechanisms to practical applications

- Power electronic drives, controls, and electric generators for large wind turbines–an overview

- Stabilization of two electricity generators

Frequently Asked Questions

What Are the Most Common Safety Hazards Associated With Using a Portable Generator?

Common safety hazards associated with using a portable generator include carbon monoxide poisoning, electric shock, and fire. To mitigate these risks, proper generator maintenance and adherence to safety precautions such as proper ventilation and grounding are necessary.

How Do I Properly Connect and Ground a Portable Generator to My Home’s Electrical System?

Properly connecting a portable generator to a home’s electrical system involves ensuring the generator is grounded and following specific guidelines for safe installation. This process ensures proper functioning and reduces the risk of electrical hazards.

Can I Safely Use a Portable Generator Indoors or in a Closed Space?

The safety of using a portable generator indoors or in a closed space depends on following proper ventilation guidelines. Adequate ventilation is necessary to prevent the build-up of harmful gases and ensure the well-being of individuals.

Are There Any Specific Tools or Equipment Required for Regular Maintenance of a Portable Generator?

Regular maintenance of a portable generator requires proper cleaning and fuel system maintenance. This entails periodic inspection, cleaning of filters, spark plug replacement, fuel stabilizer usage, and regular oil changes to ensure optimal performance and longevity.

How Often Should I Service or Tune-Up My Portable Generator to Ensure Its Optimal Performance?

The frequency of servicing a portable generator for optimal performance depends on various factors such as usage, fuel type, and environmental conditions. Regular maintenance is recommended to ensure reliability and longevity.

How do you test if a generator is working?

To check if a generator is working, follow these simple steps: First, turn OFF the mainline breaker. Listen for the generator to start and the transfer switch to click. Allow the generator to run for about 10 minutes. After the test, remember to turn the mainline breaker back ON.

How do I know if my generator is bad?

Signs of a malfunctioning generator include visible damage, start-up delays, inconsistent power, no electricity output despite the generator running, strange smells or noises, and if the generator hasn’t been started in more than 6 months.

How do you inspect a portable generator?

When inspecting a portable generator, check the fuel for quality, test the battery, clean the air filter, inspect the carburetor, and ensure proper liquid levels. Common generator issues involve fuel quality, battery failure, and low liquid levels. Regular inspections help prevent these problems.