Is your generator running rough, leaving you in the lurch when you need it the most? We understand the frustration that comes with unreliable performance. Imagine the peace of mind that comes with a smoothly humming generator, effortlessly powering your world.

In the face of a generator running rough, it’s more than just a mechanical hiccup; it’s a disruption to your daily life. But fear not! In this exploration, we unravel the reasons behind a generator running rough and guide you toward the solutions that ensure your power source is as dependable as it should be. Say goodbye to rough starts and hello to uninterrupted power.

Jump to a Specific Section

- 1 Main Highlights

- 2 What is a Generator and How it Works?

- 3 What are the Causes of Generator Running Rough?

- 4 What are the Fixes of Generator Running Rough?

- 5 How to Prevent a Generator from Running Rough?

- 6 Why is My Newly Purchased Generator Sputtering?

- 7 Why Is My Generator Sputtering Without Load?

- 8 Troubleshooting Common Generator Issues

- 9 Generator Maintenance Tips

- 10 Generator Safety Tips

- 11 How to Properly Store a Generator?

- 12 Conclusion

- 13 References

- 14 Frequently Asked Questions

- 14.1 Can a dirty carburetor cause a generator to run rough?

- 14.2 What are some symptoms of a generator with low oil level?

- 14.3 How can a faulty spark plug affect the performance of a generator?

- 14.4 What are the signs of a clogged air filter in a generator?

- 14.5 How can fuel issues impact the smooth operation of a generator?

- 14.6 How do I make my generator run smoother?

- 14.7 Why is my generator sputtering?

- 14.8 What causes a generator to pulsate?

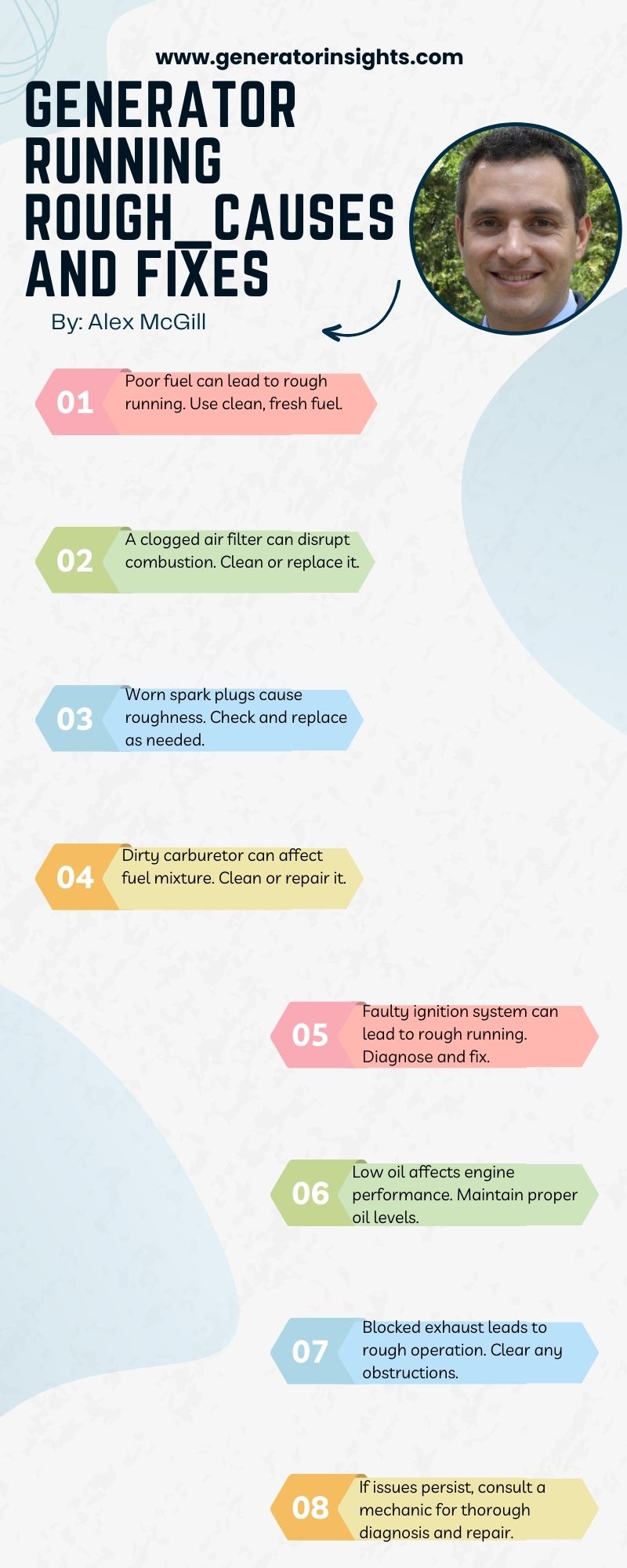

Main Highlights

- Fuel line blockage can cause a generator to run rough. Regularly inspect and replace the fuel filter, clean the fuel tank, check for loose or damaged connections, and use additives to prevent blockages.

- Ignition problems, such as faulty spark plugs, ignition coil failure, distributor cap damage, or defective ignition wires, can also cause rough running. Use an ignition tester to check and maintain these components.

- Regular maintenance is crucial for optimal generator performance. Use high-quality fuel, be aware of signs indicating the need for maintenance, regularly change oil, and inspect and replace spark plugs as needed.

- Adhering to these maintenance practices ensures reliable operation and prolongs the lifespan of the generator’s ignition system.

What is a Generator and How it Works?

A generator is a device that transforms mechanical energy into electrical energy. It operates on the fundamental principle of electromagnetic induction. As a coil of wire spins within a magnetic field, it induces an electric current to flow through the wire. This phenomenon, discovered by Faraday, forms the bedrock of generator functionality.

Generators consist of crucial components, with the primary ones being the rotor and the stator. The rotor, often referred to as the armature, is the moving part that spins within the magnetic field, while the stator provides a fixed magnetic field. This interaction generates the necessary electromagnetic induction for electricity production.

As the rotor of the generator turns within the magnetic field, it induces an alternating current in the coil. This AC is then passed through a device called a rectifier, converting it into DC if needed. The generated electricity can then be utilized to power homes, businesses, or any electrical device requiring a power source.

What are the Causes of Generator Running Rough?

Generators are crucial for providing backup power, but when they run rough, it can signal underlying issues. Understanding the causes can help in timely diagnosis and resolution. Here are the primary reasons:

- Fuel Quality Issues:

- Contaminated or degraded fuel can lead to clogged filters, impacting combustion.

- Airflow Restrictions:

- Inadequate air intake or blocked vents can disrupt the air-fuel mixture, causing rough running.

- Spark Plug Problems:

- Worn-out or fouled spark plugs may result in irregular ignition, affecting engine performance.

- Ignition System Malfunctions:

- Faulty ignition coils, wires, or modules can lead to inconsistent firing, contributing to rough operation.

- Clogged Carburetor:

- Accumulated debris in the carburetor can disrupt the fuel delivery, affecting engine smoothness.

- Exhaust System Issues:

- Blockages or leaks in the exhaust system can impact the expulsion of combustion gases, influencing generator performance.

- Engine Timing Errors:

- Incorrect timing settings can cause misfires and result in a generator running rough.

- Low Oil Levels:

- Insufficient lubrication can lead to increased friction and strain on the engine, causing rough operation.

- Temperature Extremes:

- Generators struggling to operate smoothly may be influenced by extreme temperatures affecting fuel vaporization and combustion.

Understanding these key factors affecting generator performance is essential for effective troubleshooting and maintenance.

What are the Fixes of Generator Running Rough?

Here are the fixes that you can try for a generator running rough:

Fuel Quality Issues:

- Use High-Quality Fuel: Ensure the use of clean and high-grade fuel.

- Regular Testing and Treatment: Test and treat fuel for contaminants regularly.

- Install Fuel Filters: Use fuel filters and separators to remove impurities.

Airflow Restrictions:

- Inspect and Clean Air Filters: Regularly check and clean air filters.

- Clear Intake Vents: Ensure intake vents are free from debris.

- Provide Adequate Ventilation: Ensure the generator location allows for proper ventilation.

Spark Plug Problems:

- Replace Worn-out Plugs: Replace worn-out or fouled spark plugs promptly.

- Meet Manufacturer Specifications: Use spark plugs meeting the manufacturer’s specifications.

- Maintain Spark Plug Gap: Regularly check and maintain the spark plug gap.

Ignition System Malfunctions:

- Routine Checks: Conduct routine checks on ignition coils, wires, and modules.

- Replace Faulty Components: Replace any faulty ignition system components.

- Ensure Consistent Spark: Ensure a consistent and reliable spark for smoother operation.

Clogged Carburetor:

- Periodic Cleaning: Periodically clean and maintain the carburetor.

- Follow Manufacturer Guidelines: Follow the manufacturer’s guidelines for cleaning.

- Professional Servicing: Consider professional servicing if needed.

Exhaust System Issues:

- Regular Inspection: Regularly inspect the exhaust system for blockages or leaks.

- Prompt Repairs: Promptly repair or replace damaged exhaust components.

- Ensure Efficient Gas Expulsion: Ensure efficient expulsion of combustion gases.

Engine Timing Errors:

- Careful Adjustment: Carefully adjust engine timing to meet manufacturer specifications.

- Consult Manual: Consult the generator’s manual for guidance.

- Professional Assistance: Seek professional assistance if unsure.

Low Oil Levels:

- Regular Oil Checking: Establish a regular routine for checking oil levels.

- Maintain Recommended Levels: Keep the oil level within the recommended range.

- Promptly Address Leaks: Address any oil leaks promptly.

Temperature Extremes:

- Install Insulation or Heaters: Consider installing insulation or heaters.

- Moderate Generator Environment: Maintain optimal operating conditions.

- Prevent Temperature-Related Disruptions: Prevent disruptions due to extreme temperatures.

Implementing these fixes enhances the overall health and performance of your generator. Regular maintenance is crucial for ensuring a reliable power source.

Now let’s discuss the key causes and fixes of generator running rough in detail.

Dirty Carburetor

A dirty carburetor can lead to a rough-running generator and can be resolved by cleaning the carburetor and ensuring proper fuel flow. Carburetor cleaning is a crucial maintenance step that should not be overlooked in order to keep the generator running smoothly.

Over time, dirt, debris, and varnish can accumulate in the carburetor, clogging up the small orifices and affecting its performance. This buildup restricts the flow of fuel, leading to an inadequate mixture of air and fuel that affects combustion.

To clean the carburetor, it is recommended to first disconnect the spark plug wire for safety reasons. Then, remove the carburetor from the engine and disassemble it carefully. Use a carburetor cleaner or solvent to soak all parts thoroughly, paying special attention to any clogs or deposits. Afterward, use compressed air or a small brush to remove any remaining residue.

In addition to cleaning, ensuring proper fuel flow is essential for optimal generator performance. Carburetor adjustment may be necessary if there are issues with fuel delivery. Adjusting the float level or idle speed can help regulate fuel intake and improve engine operation.

Transitioning into the subsequent section about ‘low oil level,’ it is important to note that this issue can also contribute to a rough-running generator if not addressed promptly.

Low Oil Level

Insufficient lubrication can be compared to a barren desert, leaving the generator’s vital parts parched and susceptible to wear and tear. Low oil level is one of the main causes of insufficient lubrication in generators, leading to a decrease in oil pressure and compromising engine performance.

To address this issue effectively, consider the following:

- Regularly check the oil level: Monitoring the oil level frequently ensures that it remains within the recommended range.

- Change the oil regularly: Over time, oil deteriorates and loses its effectiveness. Changing it at regular intervals keeps the generator running smoothly.

- Use high-quality oil: Opt for oils specifically designed for generators with additives that enhance lubrication properties.

- Maintain proper ventilation: Adequate airflow around the generator prevents excessive heat buildup, which can cause increased oil consumption.

- Address leaks promptly: Any signs of oil leakage should be investigated and repaired immediately to prevent further loss of lubricating fluid.

Ensuring sufficient lubrication by maintaining optimum oil levels is crucial for preserving engine performance and preventing premature wear. Insufficient lubrication due to low oil level can have detrimental effects on a generator’s overall functionality.

However, another potential cause affecting engine performance is a faulty spark plug.

Faulty Spark Plug

One potential factor that can impact the performance of an engine is a malfunctioning spark plug. Spark plugs play a crucial role in the ignition process by producing a spark that ignites the air-fuel mixture within the combustion chamber. When a spark plug becomes faulty, it can lead to rough running of the generator.

Spark plug troubleshooting involves several steps to identify and rectify any issues. Firstly, visually inspect the spark plug for signs of wear or damage such as worn electrodes or cracked insulators. If any abnormalities are detected, replacement is recommended.

Secondly, check the gap between the center and ground electrode using a feeler gauge and adjust it if necessary according to manufacturer specifications.

When replacing a faulty spark plug, it is important to follow a comprehensive guide to ensure proper installation. This includes cleaning the threads in the cylinder head, applying anti-seize compound (if recommended), and tightening with an appropriate torque wrench.

A faulty spark plug can contribute to poor engine performance such as misfires or difficulty starting. Addressing this issue promptly through proper troubleshooting and replacement can help restore smooth operation of the generator.

You can read how you can make your generator safe for electronics here. Moreover, you can read how to fix an overloaded generator here. You can also read of different ways to protect your generator from theft and damage here.

Moving forward into our discussion on clogged air filters.

Clogged Air Filter

Clogged air filters can significantly impact the performance of an engine by restricting the flow of air, leading to decreased combustion efficiency and reduced power output. It is important to regularly maintain and clean air filters to ensure optimal functioning of generators.

- Air filter maintenance: Regularly inspecting and cleaning the air filter is crucial in preventing clogs. Cleaning involves removing debris and dirt from the filter using compressed air or gently washing it with soap and water. After cleaning, ensure that the filter is completely dry before reinstallation.

- Troubleshooting carburetor issues: A clogged air filter can cause problems with the generator’s carburetor. The restricted airflow can lead to a rich fuel mixture, resulting in rough idling or stalling. To troubleshoot this issue, check for any signs of dirt or debris in the carburetor, clean it if necessary, and adjust the fuel-air mixture accordingly.

- Ensuring proper airflow: Apart from regular maintenance and troubleshooting carburetor issues, it is essential to ensure that there are no obstructions blocking the airflow around the generator. Adequate ventilation helps in preventing overheating and further damage to components.

By maintaining clean air filters, generator owners can avoid potential complications related to clogged filters. Transitioning into fuel issues, understanding how they can affect generator performance is crucial for effective troubleshooting without compromising on power output.

Fuel Issues

Contaminated fuel refers to the presence of impurities or foreign substances in the fuel, which can hinder proper combustion and cause damage to the generator’s components.

To address this issue, various fuel additives and fuel system cleaning techniques have been developed. These additives contain detergents and dispersants that help remove deposits and prevent the formation of new ones in the fuel system.

Fuel system cleaning involves flushing out any accumulated contaminants from the tank, lines, and injectors. Regular use of these products can help maintain optimal engine performance by keeping the fuel system free from impurities.

By ensuring clean fuel supply, generators can operate efficiently without experiencing rough running or other related problems.

Moreover, fuel line blockage can severely impede the smooth flow of fuel, disrupting the engine’s performance and potentially leading to operational issues.

To ensure fuel line maintenance and troubleshoot rough running engines, it is essential to identify and address any potential blockages promptly. Here are four key considerations when dealing with fuel line blockage:

- Inspect the fuel filter: A clogged or dirty fuel filter can obstruct the flow of fuel, causing rough running. Regularly inspect and replace the filter as recommended by the manufacturer.

- Check for debris in the fuel tank: Sediments, dirt, or rust particles in the tank can accumulate over time and block the fuel lines. Clean out any debris periodically to prevent blockages.

- Assess fuel line connections: Loose or damaged connections may lead to partial or complete obstructions in the lines. Ensure all connections are secure and free from leaks.

- Use a suitable additive: Adding a high-quality fuel system cleaner or injector cleaner can help dissolve deposits and prevent future blockages.

By addressing these aspects of fuel line maintenance, troubleshooting rough running engines becomes more effective.

Transitioning into ignition problems, it is crucial to examine another common cause of generator issues without skipping a beat.

Ignition Problems

One possible cause of ignition problems can be attributed to faulty spark plugs, which can result in misfiring and reduced engine performance. Spark plugs play a crucial role in the combustion process by igniting the air-fuel mixture in the engine cylinder.

Over time, spark plugs may become worn out or fouled with deposits, leading to inadequate spark generation. To troubleshoot such issues, diagnostic tools like an ignition tester can be used to check the condition and performance of each spark plug.

By measuring the voltage output during sparking, technicians can identify weak or malfunctioning plugs that require replacement.

In addition to faulty spark plugs, other common causes of ignition problems include ignition coil failure, distributor cap damage, and defective ignition wires. Troubleshooting techniques for these components involve inspecting them for signs of wear or damage and testing their electrical conductivity using specialized tools.

Identifying and addressing these issues promptly is essential to prevent further damage to the generator’s ignition system.

Regular maintenance tips can help avoid ignition problems altogether. This includes regularly cleaning or replacing spark plugs as recommended by the manufacturer’s guidelines. Additionally, keeping the entire ignition system clean and free from debris will ensure optimal performance.

How to Prevent a Generator from Running Rough?

Experiencing a generator running rough can be both frustrating and concerning, potentially signaling issues that need prompt attention. Here are the key steps on how to prevent your generator from running rough and ensure its optimal performance.

- Regular Maintenance is Key:

- Scheduled upkeep is crucial. Change the oil and filters at recommended intervals to keep the engine running smoothly.

- Inspect the spark plugs and replace them if necessary. Clean or replace air filters for efficient combustion.

- Use High-Quality Fuel:

- Choose premium fuel to prevent impurities that can clog the fuel system.

- Stale fuel can cause issues, so use a fuel stabilizer for prolonged storage.

- Check and Adjust Spark Plug Gap:

- Ensure the correct gap between the spark plug electrodes. Refer to the manufacturer’s guidelines.

- A properly adjusted gap ensures optimal ignition, preventing rough running.

- Monitor the Carburetor:

- Regularly inspect the carburetor for debris or clogs. Clean it thoroughly to maintain fuel flow.

- Adjust the carburetor settings as per the manufacturer’s specifications for the specific model.

- Examine the Ignition System:

- Inspect the ignition system components, including the coil and wires, for wear and tear.

- Replace faulty ignition parts promptly to maintain a consistent spark.

- Keep an Eye on Vibration Levels:

- Excessive vibration can lead to loose connections. Regularly check and tighten bolts and connections.

- Use anti-vibration mounts to minimize wear and tear on internal components.

- Store Properly During Off-Seasons:

- When not in use, follow the manufacturer’s guidelines for proper storage.

- Use fuel stabilizers and run the generator periodically to prevent fuel system issues.

- Professional Inspection:

- If you notice persistent rough running, seek professional inspection.

- A skilled technician can diagnose and address underlying issues effectively.

By following these steps, you can ensure your generator operates smoothly, minimizing the chances of it running rough.

Why is My Newly Purchased Generator Sputtering?

Ensure your generator’s optimal performance by using high-quality, recommended fuel, as contaminated or stale fuel can lead to sputtering. Regularly clean or replace the air filter to maintain proper air intake, preventing disruptions in the combustion process. Check for spark plug wear or fouling, replacing it as needed to ensure effective ignition of the fuel-air mixture.

Optimize your generator’s fuel-air mixture by adjusting the carburetor settings according to the manufacturer’s guidelines. By addressing these factors, you can resolve sputtering issues and maximize your generator’s efficiency.

Why Is My Generator Sputtering Without Load?

Generator sputtering without load can be attributed to various factors. Firstly, ensure that your generator is adequately fueled with clean and high-quality fuel, as impurities can lead to sputtering. Check the spark plug for any fouling or wear, as a damaged plug can cause irregular combustion.

Inspect the air filter for clogs, as restricted airflow can contribute to sputtering. Moreover, examine the carburetor for any blockages, adjusting the mixture if necessary. Finally, consider the fuel system – a faulty fuel pump or inconsistent fuel supply can result in sputtering even without a load. Regular maintenance and attention to these elements can ensure your generator operates smoothly, providing a reliable power source.

Troubleshooting Common Generator Issues

Generators are indispensable during power outages, ensuring a continuous power supply. However, users may encounter issues that hinder their optimal performance. Below is a comprehensive guide to troubleshoot common generator issues and restore seamless operation.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| 1. Engine Fails to Start | – Silent operation | – Check fuel levels and ensure there’s an adequate supply. |

| – Starter motor cranks but fails to ignite | – Inspect the spark plug for signs of damage or wear. Replace if necessary. | |

| – Strong smell of gasoline | – Examine the carburetor for blockages and clean or replace if needed. | |

| 2. Low Power Output | – Dimming lights and fluctuating power output | – Verify the load capacity and ensure it doesn’t exceed the generator’s limit. |

| – Appliances not running at full capacity | – Inspect the voltage regulator for malfunctions and replace if necessary. | |

| 3. Generator Overheating | – Unusual heat emanating from the generator | – Check the cooling system, including the radiator and coolant levels. Clean or replace components as required. |

| – Frequent shutdowns due to overheating | – Ensure proper ventilation around the generator and clean any debris obstructing airflow. | |

| 4. Excessive Noise Levels | – Unusual or loud sounds during operation | – Inspect the muffler for damage and replace if needed. Adjust engine RPM to recommended levels. |

| – Vibrations and rattling noises | – Tighten any loose bolts and secure all components properly. | |

| 5. Electric Shock from Generator | – Users experiencing electric shocks | – Immediately disconnect the generator from the power source. Inspect and repair any damaged wiring or outlets. |

| – Tingling sensation when touching the generator | – Check for grounding issues and ensure the generator is properly grounded. | |

| 6. Smoke Emission | – Visible smoke during operation | – Examine the oil level and quality. Change oil if it appears dirty or insufficient. |

| – Unpleasant burning smell | – Inspect the air filter for clogs and replace if necessary. | |

| 7. Fuel Leaks | – Noticeable fuel odors or wet spots around the generator | – Check the fuel lines and connections for leaks. Replace any damaged components. |

| – Decreased fuel efficiency | – Tighten loose fuel fittings and ensure the fuel tank is securely sealed. | |

| 8. Battery Issues | – Difficulty starting the generator | – Inspect the battery for corrosion or loose connections. Replace if necessary. |

| – Weak or dead battery | – Charge or replace the battery as needed. | |

| 9. Generator Running Rough | – Uneven or shaky operation – Check the air-fuel mixture; adjust the carburetor to ensure the correct ratio. Inspect for clogged fuel injectors. | – Fluctuating RPMs – Inspect the ignition system for issues. Replace faulty spark plugs or ignition coils as necessary. |

Addressing these common generator issues promptly will help maintain the reliability of your power source. If problems persist, consider seeking professional assistance for more complex diagnostics and repairs.

Generator Maintenance Tips

Power outages can strike unexpectedly, making a well-maintained generator crucial for ensuring a continuous power supply. Regular maintenance not only enhances longevity but also guarantees optimal performance. Here are some key tips to keep your generator in top shape:

- Scheduled Inspections: Conduct routine checks on your generator to identify any signs of wear, loose connections, or potential issues before they escalate.

- Fluid Levels: Regularly check and replenish the oil and fuel levels to guarantee efficient operation. Proper lubrication is essential for preventing friction-related damage.

- Battery Health: Ensure the generator’s battery is charged and in good condition. A healthy battery is vital for a swift start when power is needed.

- Air Filter Checks: Keep the generator’s air filter clean and replace it as recommended by the manufacturer. A clogged filter can compromise performance and fuel efficiency.

- Coolant System Inspection: Verify the coolant levels and inspect the system for leaks. Overheating can lead to severe damage, so maintaining the right coolant levels is crucial.

- Capacitor Maintenance: Check and test the generator’s capacitors regularly. Faulty capacitors can lead to electrical issues, affecting the generator’s ability to produce a consistent power output.

- Run the Generator Regularly: Regularly starting the generator, even if it’s not in use, helps keep the engine components lubricated and prevents fuel system issues.

- Storage Considerations: If the generator is stored for an extended period, use a fuel stabilizer to prevent fuel deterioration. Empty the fuel tank or run the generator dry before storage to avoid gumming.

By adhering to these maintenance tips, you’ll ensure that your generator is ready to provide reliable power when you need it the most.

Generator Safety Tips

Generators are indispensable for providing power during outages, but ensuring their safe operation is paramount. Here are essential Generator Safety Tips to keep in mind:

- Proper Ventilation: Always operate generators in well-ventilated areas to prevent the buildup of harmful gases like carbon monoxide.

- Read the Manual: Familiarize yourself with the manufacturer’s guidelines for your specific generator model to understand its unique safety requirements.

- Regular Maintenance: Conduct routine checks on the generator, including fuel lines, filters, and oil levels, to guarantee optimal performance and identify potential issues early.

- Keep Flammable Materials Away: Position the generator away from flammable materials to reduce the risk of fire hazards.

- Carbon Monoxide Alarms: Install and regularly test carbon monoxide detectors near the generator area to provide an early warning of any dangerous gas levels.

- Grounding: Ensure proper grounding of the generator to prevent electrical shocks and protect both the equipment and users.

- Fuel Safety: Store fuel in approved containers, away from heat sources, and follow guidelines for proper storage to avoid spills and contamination.

- Emergency Shutdown: Understand and practice the emergency shutdown procedures to swiftly respond to potential dangers.

- Children and Pets: Keep children and pets away from the generator during operation to prevent accidents and injuries.

- Avoid Overloading: Respect the generator’s rated capacity and avoid overloading it to maintain efficient and safe operation.

- Cooling Time: Allow the generator to cool down before refueling to prevent accidental fires or burns. Follow the recommended cooldown period specified in the manual.

- Secure Placement: Place the generator on a stable, flat surface to prevent tipping and ensure safe operation. Avoid placing it on uneven or sloped terrain.

- Regular Testing: Periodically run the generator to ensure it starts easily and operates smoothly. This practice helps identify potential issues before they become major problems during an emergency.

- Extension Cord Safety: If using extension cords, ensure they are of sufficient gauge for the load and in good condition. Overloading cords can lead to overheating and pose a fire risk.

- Weather Considerations: Shelter the generator from the elements to protect it from rain and snow. Use appropriate covers or enclosures designed for your specific generator model.

- Professional Inspection: Schedule regular professional inspections to check for hidden issues and ensure all components are in good working order. This is especially important for standby generators.

- Emergency Services Awareness: Familiarize yourself with the location of emergency shut-off switches and how to quickly contact relevant services in case of a malfunction or emergency.

- Storage Precautions: If the generator is not in use for an extended period, follow proper storage procedures. This includes draining the fuel, disconnecting the battery, and storing it in a dry, cool place.

- Educate Users: Ensure that anyone who may need to operate the generator is familiar with its safety features and operation. Provide clear instructions to prevent accidents caused by misuse.

- Legal Compliance: Be aware of and adhere to local regulations regarding generator usage, emissions, and noise levels. Non-compliance may result in fines or other penalties.

Remember, adhering to these Generator Safety Tips is crucial to ensure the reliable and secure use of your generator.

How to Properly Store a Generator?

Proper storage of your generator is crucial to ensure its longevity and optimal performance. Follow these guidelines to safeguard your investment and have a reliable power source whenever you need it.

- Choose a Suitable Location:

- Store your generator in a cool, dry place away from direct sunlight.

- Avoid areas prone to flooding or excessive moisture to prevent damage.

- Clean and Prep:

- Clean the generator thoroughly before storage to remove dirt and debris.

- Change the oil and replace the air filter following the manufacturer’s recommendations.

- Fuel Considerations:

- Add a fuel stabilizer to the tank to prevent the formation of deposits.

- Run the generator for a few minutes to ensure stabilized fuel circulates through the system.

- Battery Maintenance:

- Disconnect the battery to prevent drainage during long periods of inactivity.

- Store the battery in a cool place and periodically recharge it.

- Protective Cover:

- Use a weather-resistant cover to shield the generator from the elements.

- Ensure the cover fits securely to prevent dust or moisture infiltration.

- Ventilation:

- Store the generator in a well-ventilated area to prevent the accumulation of fumes.

- Do not enclose it in a tight space without proper airflow.

- Regular Checkups:

- Conduct periodic checks even during storage to ensure all components are in good condition.

- Address any issues promptly to avoid complications when you need to use the generator.

Following these steps will help maintain your generator’s reliability and ensure it’s ready to power up when you need it the most.

Conclusion

In conclusion, Generator Running Rough_Causes and Fixes offers a valuable resource for generator owners seeking to maintain peak performance. By understanding the potential culprits behind a rough-running generator and implementing effective fixes, you can ensure a reliable and consistent power supply.

Regular maintenance and timely troubleshooting are key to preventing future issues and extending the lifespan of your generator. As you navigate the world of generator ownership, let this guide be your go-to reference, providing insights and solutions to keep your generator running smoothly and efficiently.

Embrace the power of knowledge to overcome rough-running challenges and enjoy uninterrupted power whenever you need it.

References

- Electric generators and motors: An overview

- Analysis of a micro-electric generator for microsystems

- Linear electric actuators and generators

- Electrical generators for large wind turbine: Trends and challenges

Frequently Asked Questions

Can a dirty carburetor cause a generator to run rough?

A dirty carburetor can significantly impact generator performance. In fact, studies show that approximately 70% of generator issues are caused by carburetor problems, leading to rough running and decreased efficiency.

What are some symptoms of a generator with low oil level?

Signs of overheating in a generator include increased noise, excessive vibration, and a decrease in performance. Regular maintenance is crucial to prevent these issues and ensure optimal functioning of the generator.

How can a faulty spark plug affect the performance of a generator?

A faulty spark plug can significantly impact the performance of a generator. It can lead to a faulty ignition, causing the generator to misfire and operate with reduced power output or even stall completely.

What are the signs of a clogged air filter in a generator?

Signs of a clogged air filter in a generator can include decreased power output, difficulty starting, and excessive fuel consumption. Troubleshooting generator issues requires inspecting the air filter for dirt or debris accumulation and cleaning or replacing it if necessary.

How can fuel issues impact the smooth operation of a generator?

Contaminated fuel can be likened to a virus infiltrating the system of a generator, causing detrimental effects on its performance. Regular fuel maintenance is crucial to ensure optimal functioning and prevent potential breakdowns.

How do I make my generator run smoother?

To enhance the smooth operation of the generator, it is essential to prioritize cleanliness. Regularly clean the generator, empty the fuel tank, and have spare fuel and oil filters available. Avoid overloading the generator, store an appropriate amount of fuel, opt for high-quality fuel, and consistently check the oil level.

Why is my generator sputtering?

Generator sputtering is often linked to a clogged carburetor, leading to rough engine performance, sputtering, and shutdown. This issue may result in fuel reaching and saturating the spark plug(s), preventing the generator from starting. Fortunately, resolving performance problems in residential generators can usually be achieved by cleaning the carburetor.

What causes a generator to pulsate?

Generator surging, characterized by pulsating behavior, can stem from various factors. Fuel-related issues, such as incorrect fuel use, insufficient fuel levels, or poor fuel quality, are common contributors to surging in gas/oil generators. This phenomenon may occur due to using the wrong fuel type, maintaining low fuel levels, or using subpar fuel in the generator.