Embark on a journey into the heart of innovation as we unravel the captivating world of electricity generation. Ever wondered, in the hum of modern life, How does an electric generator work? It’s not just about machines; it’s about empowering people. Picture this: a seamless blend of engineering marvels and human ingenuity. Imagine turning a simple flick of a switch into a conduit for transformation, where the invisible dance of electrons powers our homes and fuels our aspirations.

Join us as we demystify the magic behind the switch, exploring the dynamic interplay that illuminates our lives and sparks the flame of curiosity.

Core Lessons

- Electric generators convert mechanical energy to electrical energy using a combination of stator and rotor with magnets and poles.

- Generators use a fuel source and an engine as a power source. The fuel system includes a pump, injectors, fuel tank, and filter, while the voltage regulator maintains the correct voltage level.

- Regular maintenance, including proper ventilation, cooling and exhaust systems, lubrication, and battery charging, is essential for reliable generator operation.

- There are different types of generators, including whole-house, portable, inverter, and solar generators, each with specific advantages and characteristics. Alternators produce AC current and are lighter and more efficient, while generators produce DC current and are larger and heavier.

What is an Electric Generator?

An electric generator is a device that converts mechanical energy into electrical energy. It plays a crucial role in generating the electricity we use in our daily lives. The basic principle behind a generator is electromagnetic induction.

Generators are vital for ensuring a continuous and reliable power supply. They are essential in situations where a direct connection to a power grid is unavailable, such as remote areas or during power outages. Portable generators are also widely used for various applications, including camping and construction sites.

How Does an Electric Generator Work?

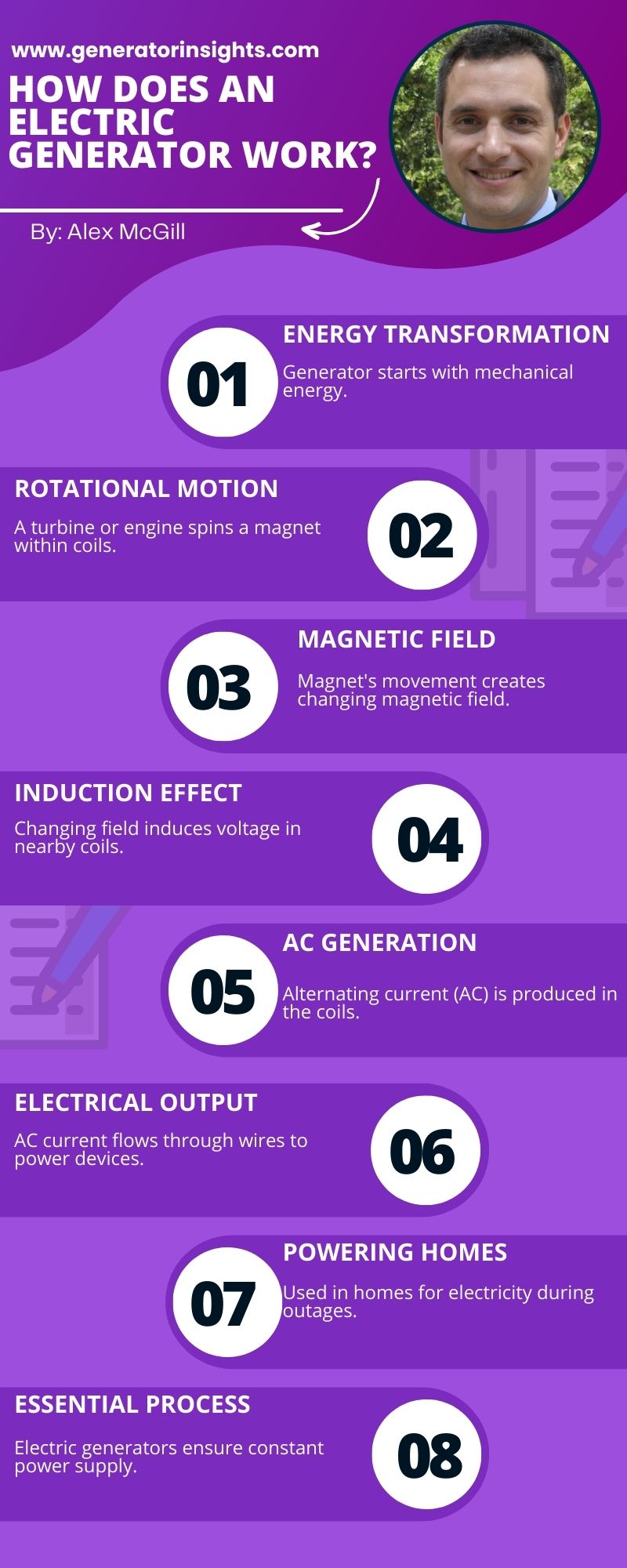

Electric generators transform mechanical energy into electrical energy through a process based on Faraday’s law of electromagnetic induction. In simpler terms, a generator converts kinetic energy (motion) into electrical energy.

The key components of an electric generator include a rotor (the moving part) and a stator (the stationary part). As the rotor spins within a magnetic field created by the stator, it induces an electric current in nearby coils. The principle of electromagnetic induction explains that a changing magnetic field induces an electric current in a conductor. In the case of a generator, this change occurs as the rotor continuously moves within the magnetic field.

To delve into more detail, when the rotor turns, it produces an alternating current (AC) as the magnetic field around the coils fluctuates. In many applications, this AC is then transformed into direct current (DC) using a device called a rectifier. The generated electricity can be harnessed for various purposes, from powering homes to running industrial machinery.

How Does an Electric Generator Produce Power?

Electric generators play a crucial role in converting mechanical energy into electrical energy, providing power for various applications. Understanding the process of how an electric generator produces power is essential for appreciating its significance.

- Magnetic Field Setup:

- Rotor Rotation: The generator’s rotor, typically a coil of wire, is connected to a mechanical energy source, such as a turbine. As the rotor spins, it induces a rotating magnetic field.

- Stator and Coil Interaction:

- Stationary Stator: Surrounding the rotor is the stator, which contains coils of wire. These coils are crucial for the generation of electrical power.

- Faraday’s Law: According to Faraday’s law of electromagnetic induction, a changing magnetic field induces an electromotive force (EMF) in a nearby conductor.

- Electromagnetic Induction:

- Flux Variation: As the rotor’s magnetic field rotates, it causes a continuous change in magnetic flux passing through the stator coils.

- EMF Generation: This changing flux induces an EMF in the stator coils, resulting in the generation of an electric current.

- Alternating Current (AC) Generation:

- AC Output: The induced current in the stator coils is alternating in nature, constantly changing direction.

- Voltage Production: The alternating current produced in the stator coils corresponds to the rotational motion of the rotor.

- Conversion to Usable Power:

- Rectification (if needed): In some applications, the generated AC may be rectified to direct current (DC) using devices like diodes.

- Power Distribution: The generated electrical power is then distributed through a power grid or used locally to drive electrical devices.

What are Parts of an Electric Generator?

An engine, an alternator, a fuel system, a voltage regulator, cooling and exhaust systems are all part of a generator. Together they work to efficiently produce the power you need for your home or business.

Engine

An internal combustion engine is typically used as the power source for an electric generator. This type of engine provides mechanical energy to turn the generator shaft, which in turn creates electricity through the use of a coil and magnet system known as an alternator.

The internal combustion engine works by combining air and fuel inside the cylinders, causing a rapid combustion process. This combustion process causes reciprocating motion in pistons that are connected to crankshafts, ultimately transferring power to the generator shaft.

| Engine | Alternator |

|---|---|

| Combustion Process | Coil & Magnet System |

| Reciprocating Motion | Generates Electricity |

| Transfers Power | Shaft Rotation |

| Cylinders | Magnets |

The transfer of energy from the internal combustion engine to the alternator is what allows electricity to be produced from an electric generator. As such, this component plays a critical role in powering up homes and businesses with electrical energy. Without it, these activities would not be possible!

Alternator

The alternator is a crucial component in the production of electricity, utilizing a coil and magnet system to generate power from the rotation of its shaft. The alternator works by allowing alternating current (AC) to be generated through induction.

It consists of two main parts: an armature winding that produces the AC voltage, and a stator that contains a permanent magnet or electromagnet which supplies the magnetic field needed for induction.

As the alternator rotates, it creates an electromagnetic field that induces current into its coil windings which are connected to external circuits. This current is then used to power electric devices such as lights, motors, and pumps. To maximize efficiency, the engine must be running at full load when using an alternator.

Moving on from this component, another crucial part of generating electricity is the fuel system.

Fuel System

Your car’s fuel system is the key to keeping your engine running and producing electricity for all your electronic needs. It consists of components such as a pump, injectors, fuel tank, and filter. The pump is responsible for making sure that gas gets from the tank to the engine in an efficient way.

The injectors are responsible for delivering precise amounts of fuel into the cylinders of the engine. The filter is there to make sure that only clean gas enters the system, ensuring proper operation.

The fuel system works with several other parts of the car in order to ensure that power is generated efficiently. This includes working with the alternator, which charges up a battery within your vehicle so you can use it when you need it most. It also works with a voltage regulator, which helps maintain consistent amounts of voltage being sent out from the alternator to keep everything functioning properly.

All these pieces work together to create reliable electricity for all your needs!

Voltage Regulator

You need a voltage regulator to keep your car’s electrical system running smoothly. It is responsible for maintaining the correct voltage level in the system, preventing it from becoming too high or too low.

When the voltage becomes too high, it may cause damage to components in the car, while when it drops below a certain point, lights and other features won’t work properly. The regulator constantly monitors the current state of the electric system and either increases or decreases its output accordingly.

In addition to regulating the overall voltage of the car, some regulators also allow you to adjust settings such as idle speed or minimum charging levels. To ensure that your vehicle runs optimally, make sure you have a functioning voltage regulator installed at all times.

The next key component of an electric generator is its cooling and exhaust systems. These systems help keep temperatures within safe operating ranges so that components don’t overheat and performance isn’t affected.

Without proper cooling and exhaust systems, an electric generator could be damaged beyond repair due to excessive heat buildup. As such, these are critical parts of any well-maintained power plant setup.

Cooling and Exhaust Systems

Maintaining a properly functioning cooling and exhaust system is essential for optimal operation of your electric generator. An efficient system will reduce the risk of overheating, ensure proper ventilation is maintained and protect sensitive components from damage.

Here are 4 points to keep in mind when maintaining your electric generator’s cooling and exhaust systems:

- Make sure air intakes are clean and free of debris in order to ensure enough airflow is available to cool the engine.

- Check belts regularly for wear or cracks that may cause them to break down, leading to loss of power or overheating.

- Replace clogged fuel filters as needed, which can disrupt fuel flow and lead to engine damage if left unchecked.

- Inspect exhaust pipes for blockages that prevent the escape of combustion gasses which can build up pressure inside the engine causing it to overheat rapidly.

- Keeping these tips in mind will help you maximize efficiency while minimizing breakdowns due to poor cooling or exhaust system maintenance – allowing you to smoothly transition into looking at critical factors like lubrication system performance next.

Lubrication System

Keeping your electric generator’s lubrication system in top condition is key for smooth operation and long-term reliability. The lubrication system is critical to the reliable operation of any electric generator, so it is important to regularly check and maintain the oil levels and replace any filters as required.

A well-maintained lubrication system will reduce wear on internal components and enable superior performance over time.

Adopting a rigorous maintenance program for your electric generator’s lubrication system can help prevent serious damage to the engine, while also potentially extending its lifetime use.

By taking appropriate steps to ensure that your generator runs efficiently, you not only get more value out of it but also have peace of mind that you’re helping preserve the environment by reducing emissions from an inefficient machine. Battery charger is next on our list to explore.

Battery Charger

Ensuring your battery charger is in proper working order is essential for keeping your electric generator running smoothly. This is because the battery charger constantly replenishes energy that is lost from the generator’s battery during normal operation.

A typical battery charger consists of an AC power source, a rectifier/controller to convert the AC power into DC and regulate the charging current, and one or more batteries. The rectifier/controller will usually have some sort of indicator light to indicate when it is supplying power to the generator’s battery.

Additionally, it should have a fuse or circuit breaker in case any electrical fault occurs within the system. With all these components in place, it can help protect your electric generator from damage caused by overcharging or undercharging its battery. Next up we’ll discuss how the control panel works with an electric generator.

Control Panel

Powering up your electric generator is essential for keeping things running smoothly, so it’s crucial to understand how the control panel works. The control panel is located on the side of the electric generator and contains all the necessary controls for operating it. It includes gauges that measure voltage output, amperage output, and frequency output as well as switches to regulate these outputs.

Additionally, there are switches used to start and stop the generator as well as turn on or off any external outlets connected to it. By monitoring and adjusting these settings you can ensure your generator is running correctly. With an understanding of how the control panel works you’ll be better prepared when using your electric generator.

Frame

Now that we’ve discussed the control panel of an electric generator, let’s move on to its frame. The frame is a critical part of any electric generator because it provides a strong and steady support system for all other components.

Constructed from durable materials, such as steel or aluminum, the frame helps to protect the inner workings of the generator while keeping everything in place. It also acts as a shield against external elements like dust and debris that could harm the mechanism over time. Moreover, depending on its size and strength, it can even be used to transport or lift the generator if need be.

If you are worried about your generator not producing power, we recommend you read our guide on how to fix a generator not producing power. Moreover, if you spot your generator blowing white smoke, you can read its potential causes and fixes in our guide here.

Types of Electric Generators

You may have heard of whole house generators, portable generators, inverter generators and solar generators. Each type of generator has its own unique purpose and benefits depending on your needs. From a more permanent home solution to an easy to transport option, there is a generator that can work for you.

Let’s take a closer look at the different types of electric generators and how they can meet your power needs.

Whole House Generators

Living without power is no fun, so whole house generators can save the day! Whole house generators are installed permanently outside a home and use either propane or natural gas to generate electricity. These types of generators have many advantages over using portable ones, such as:

- They provide enough power to run all or most of your appliances in case of an outage.

- Their fuel source is convenient and cost effective for long-term use.

- They generally have a longer lifespan than portable models due to their more durable construction materials. Whole house generators offer peace of mind during times when the power goes out, but they can be expensive to purchase and install compared to portable models.

- Nevertheless, if you want reliable backup power for your entire home then a whole house generator may be the perfect choice!

Portable Generators

If you’re looking for an affordable and convenient solution for backup power, a portable generator may be the perfect choice! Portable generators are lightweight and can provide temporary power when needed. They come in a variety of sizes to fit different needs, from small-scale camping needs to larger models that can run AC units or a whole house.

They typically run on gasoline or diesel fuel, meaning they’re easy to refill and maintain. Portable generators are also relatively quiet compared to other types of generators. While they can provide enough electricity to keep essential appliances running during an outage, they shouldn’t be used as your main source of power due to safety risks associated with long-term use. Without further ado, let’s look at inverter generators.

Inverter Generators

Inverter generators are a great choice if you want reliable power in a compact package. Unlike traditional portable generators, they use advanced inverter technology to produce cleaner power with less noise and fewer emissions. Additionally, these generators offer several features that make them better suited for certain applications:

- Portability: Inverter generators are much smaller and lighter than traditional portable models, making them easy to transport and store.

- Maintenance: They require less maintenance as they have fewer moving parts and don’t need frequent oil changes.

- Noise level: They operate more quietly than conventional portable units, making them ideal for camping trips or other activities where noise is an issue. Inverter generators provide a cost-effective way to generate electricity on the go without sacrificing the quality of the output or your peace of mind.

With their efficient design and robust features, they can be an excellent choice for anyone looking for reliable power in an easy-to-manage package. Their portability makes them perfect for outdoor adventures or emergency situations when access to electricity is limited.

With this in mind, it’s no wonder why inverter generators are quickly becoming one of the most popular choices among consumers looking for dependable power solutions. From here, we’ll transition into discussing solar generators – another popular option when it comes to providing reliable off-grid power sources.

Solar Generators

Solar generators are an excellent choice if you’re looking for a reliable and sustainable source of power. They use the sun’s energy to generate electricity, meaning they don’t require fossil fuels like natural gas or diesel to operate. Solar generators have no moving parts, making them low maintenance and efficient. They can also be scaled to fit your specific needs, whether you need enough energy to run a few small appliances or an entire home during a blackout.

Additionally, solar generators are relatively inexpensive compared to other types of backup power sources. With little upkeep required and their affordability, solar generators offer an ideal solution for those looking for renewable energy solutions. Moving on from solar-powered generators, we’ll take a look at alternator vs generator systems.

Alternator Vs Generator

| Feature | Alternator | Generator |

|---|---|---|

| Function | Converts mechanical energy into alternating current (AC). | Converts mechanical energy into direct current (DC) or alternating current (AC). |

| Output Type | Typically produces AC output. | Can produce both AC and DC output depending on design. |

| Construction | Employs a rotating magnetic field and stationary coils to induce voltage. | Utilizes a rotating coil within a magnetic field to generate voltage. |

| Efficiency | Generally more efficient due to continuous AC production. | Slightly less efficient as it may require additional components for DC conversion. |

| Applications | Widely used in modern vehicles and power grids for AC distribution. | Historically used in older vehicles and specific applications requiring DC power. |

| Examples | Commonly found in cars, trucks, and power plants. | Older models of cars or in applications where DC power is specifically needed, such as battery charging. |

In summary, the choice between an alternator and a generator depends on the desired output, efficiency requirements, and the intended application. Alternators are more prevalent in modern contexts, especially in vehicles and power grids, due to their efficiency and compatibility with AC systems. Generators, on the other hand, find application in scenarios where direct current is necessary or in legacy systems.

How to Choose the Right Generator for Your Needs?

When selecting a generator, it’s crucial to assess your power needs comprehensively. This involves identifying the essential appliances and devices you intend to power during an outage or in an off-grid setting.

Calculate Your Wattage Requirements

Determine the wattage requirements of each device you plan to connect to the generator. Check the labels or user manuals for the running and starting wattage. Make a list and add up these values to get an estimate of your total power needs.

Consider Start-Up Surges

Keep in mind that some appliances, particularly those with motors, have a higher starting wattage than their running wattage. This surge is temporary but needs to be accommodated by the generator’s capacity.

Generator Size and Type

Choose a generator size that not only meets your current needs but also allows for potential future expansion. Consider whether a portable generator or a standby generator suits your requirements better. Portable generators offer flexibility, while standby generators provide automatic backup power.

Fuel Type and Runtime

Select a generator based on the available fuel types – gasoline, propane, or diesel. Consider the availability and convenience of the chosen fuel. Additionally, assess the generator’s runtime on a full tank, ensuring it meets your expected duration of use.

Noise Level

Evaluate the noise level of the generator, especially if you plan to use it in residential areas. Generators with lower decibel ratings are generally quieter and more suitable for environments where noise is a concern.

Portability and Mobility

For those needing a generator for various locations or outdoor activities, portability is key. Look for features such as handles and wheels for easy transport.

Safety Features

Prioritize generators with essential safety features such as overload protection, low-oil shutoff, and GFCI outlets. These features enhance the safety of both the generator and connected devices.

Budget Considerations

While it’s important to find a generator that meets your needs, consider your budget. Balance your requirements with the available budget to ensure a cost-effective and practical solution.

Read User Reviews

Before finalizing your decision, read user reviews and testimonials. Real-world experiences can provide valuable insights into the reliability, performance, and user-friendliness of a specific generator model.

Consultation with Experts

If you’re uncertain about your power requirements or the right generator for your needs, seek advice from professionals. Consulting with experts in the field can help you make an informed decision based on your specific circumstances.

Thus, choosing the right generator involves a thorough understanding of your power needs, careful consideration of generator features, and staying within your budget. By following these guidelines, you can ensure that the generator you select is a reliable and efficient power source for your unique requirements.

Generator Storage Tips

Generators are crucial tools, especially during power outages. Proper storage ensures they function optimally when needed. Here are some essential tips:

- Location Matters: Store the generator in a cool and dry place to prevent corrosion and damage. Avoid direct exposure to sunlight and rain, as it can affect the internal components.

- Ventilation is Key: Generators produce heat during operation. Ensure the storage area has adequate ventilation to prevent overheating. This extends the lifespan of the generator and reduces the risk of malfunctions.

- Fuel Considerations: If the generator uses fuel, store it in a well-ventilated outdoor area away from direct sunlight. Use stabilizers to prevent fuel deterioration, ensuring the generator starts smoothly when required.

- Regular Maintenance: Perform routine checks even during storage. Inspect for any signs of damage, clean the air filters, and ensure all components are in good condition. This proactive approach guarantees the generator’s reliability.

- Battery Care: For generators with batteries, disconnect the battery during storage to prevent drainage. Keep it charged periodically and ensure the terminals are corrosion-free.

- Run the Generator: Start the generator and let it run for a brief period every three months. This prevents engine parts from seizing and keeps the internal components lubricated.

- Keep it Covered: Use a generator cover to protect it from dust, debris, and insects. This simple measure prevents unnecessary wear and tear, maintaining the generator’s efficiency.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for long-term storage. They provide specific instructions tailored to the generator model, ensuring optimal performance when needed.

- Emergency Kit: Store an emergency kit alongside the generator, including basic tools, spare parts, and the user manual. This ensures you are well-prepared for any unforeseen issues that may arise.

Generator Maintenance Tips

Ensuring your generator runs smoothly is crucial for uninterrupted power supply. Follow these generator maintenance tips to keep your equipment in optimal condition.

- Regular Inspections:

- Perform monthly visual inspections to spot any leaks, loose connections, or worn-out parts.

- Check the fuel and oil levels to guarantee proper functionality.

- Oil Changes:

- Change the oil after every 100 hours of operation to prevent engine damage.

- Use the manufacturer-recommended oil type and viscosity for optimal performance.

- Air Filter Checks:

- Inspect the air filter regularly, and replace it if it’s dirty or clogged.

- A clean air filter ensures efficient combustion and fuel consumption.

- Battery Care:

- Keep the generator battery terminals clean and corrosion-free to ensure a reliable start.

- Test the battery periodically and replace it if it shows signs of weakness.

- Cooling System Maintenance:

- Check the coolant level and top it up as needed to prevent overheating.

- Clean the radiator and cooling fins to maintain efficient heat dissipation.

- Run the Generator Regularly:

- Operate the generator at least once a month with a load to prevent fuel system issues.

- This helps keep the engine and various components in good working order.

- Store Fuel Properly:

- Use clean and stabilized fuel to prevent carburetor clogs and fuel system problems.

- Rotate stored fuel to ensure freshness and avoid engine issues.

- Professional Servicing:

- Schedule annual professional maintenance to address potential problems and extend the generator’s lifespan.

- Professional technicians can conduct in-depth inspections and address issues you might overlook.

By adhering to these generator maintenance tips, you’ll enhance the longevity and reliability of your power source, ensuring it’s ready when you need it most.

Generator Safety Tips

Power outages can happen unexpectedly, making generators a valuable asset. However, ensuring their safe use is crucial. Here are essential tips to keep in mind:

- Location Matters: Place your generator in a well-ventilated area, ideally outdoors, to prevent carbon monoxide buildup.

- Read the Manual: Familiarize yourself with your generator’s manual for proper operation and maintenance instructions.

- Fuel Storage: Store generator fuel in a cool, well-ventilated place, away from potential ignition sources.

- Regular Inspections: Conduct routine checks for fuel leaks, loose connections, and any signs of wear on cables.

- Grounding: Properly ground your generator to minimize the risk of electrical shocks and ensure safe operation.

- Keep it Dry: Protect your generator from the elements by using a generator tent or covering during rainy conditions.

- Load Management: Avoid overloading your generator by calculating the total wattage of connected devices.

- Exhaust Direction: Position the generator’s exhaust away from windows and doors to prevent fumes from entering enclosed spaces.

- Cooling Time: Allow the generator to cool down before refueling to prevent accidents and ensure safe handling.

Remember, prioritizing safety when using generators is essential for both your well-being and the longevity of the equipment.

Conclusion

You now understand how does an electric generator work. Generators are made up of several parts that work together to create electricity. There are two types of generators, alternators and generators, and they have different uses.

It’s important to know the differences between them so you can choose the right one for your needs. With the right knowledge, you can be sure that your generator will keep you powered up when needed!

References

- Generating efficiency: economic and environmental regulation of public and private electricity generators in Spain

- Carbon monoxide poisoning from hurricane-associated use of portable generators–Florida, 2004

- Carbon monoxide poisoning from portable electrical generators

- Development and performance evaluation of sound proof enclosure for portable generators