Tired of the incessant hum drowning your peace? Discover the secret to serenity with our guide on How to Make a Generator Quiet. Imagine enjoying the convenience of power without the disruptive noise. In a world where tranquility is a luxury, we understand the need for a generator that seamlessly blends into your lifestyle.

Dive into a journey where silence meets power, as we unravel practical tips and tricks to transform your generator into a whisper-quiet marvel. Because your moments of quiet contemplation shouldn’t be interrupted by the roar of a generator. Unleash the power, not the noise!

Jump to a Specific Section

- 1 Main Highlights

- 2 Why are Generators Noisy?

- 3 How To Make A Generator Quiet?

- 3.1 Choose the Right Generator

- 3.2 Location

- 3.3 Face the Exhaust Pipes Up or Away from You

- 3.4 Build a Quiet Enclosure

- 3.5 Use Sound Deflectors

- 3.6 Place The Generator On a Soft Surface

- 3.7 Add a Larger Muffler

- 3.8 Use Water As Your Generator Muffler

- 3.9 Use a Sound Attenuation System

- 3.10 Use Rubber Grommets

- 3.11 Choose the Right Fuel Type

- 3.12 Apply Mass Loaded Vinyl

- 4 Troubleshooting Common Generator Issues

- 5 Generator Maintenance Tips

- 6 Generator Safety Tips

- 7 Conclusion

- 8 References

- 9 Frequently Asked Questions

- 9.1 What types of noise reduction techniques can be used?

- 9.2 Can I use a generator indoors?

- 9.3 How much maintenance is required to keep a generator quiet?

- 9.4 What is the best type of generator for a quiet operation?

- 9.5 What safety precautions should be taken when using a generator?

- 9.6 How do you reduce the noise of a generator?

- 9.7 Can you make a regular generator quieter?

- 9.8 Can you put a silencer on a generator?

Main Highlights

- Choosing the right generator type can make a big difference in noise levels.

- Building a quiet enclosure around the generator or using sound deflectors can reduce noise output.

- Placing the generator on a soft surface or adding a larger muffler can make it quieter.

- Sound attenuation systems can be installed to block noise before it leaves the generator, resulting in a quiet environment without additional hassle.

Why are Generators Noisy?

When it comes to generators, one common concern that many users encounter is the issue of noise. Understanding the reasons behind the noise generated by these essential machines is crucial for both consumers and manufacturers. So, why exactly are generators noisy?

- Engine Vibration and Operation: Generators produce noise primarily due to the inherent vibrations of their internal combustion engines. The operation of the engine involves the controlled explosion of fuel, causing rapid movement of internal components. This movement results in vibrations that propagate through the generator’s structure, producing audible sound waves.

- Exhaust System Noise: Another significant contributor to generator noise is the exhaust system. The process of expelling combustion gases produces a distinctive sound. The design and efficiency of the exhaust system play a role in determining the noise level. High-quality mufflers and advanced exhaust designs can help mitigate this aspect of generator noise.

- Generator Size and Power Output: The size and power output of a generator also impact its noise level. Larger generators with higher power ratings often have more robust engines, which can lead to increased noise levels. Conversely, smaller generators may produce less noise due to their smaller engines, but they might not meet the power demands of larger applications.

- Airflow and Cooling Fans: Generators require efficient cooling to prevent overheating during operation. Cooling fans, essential for this purpose, can contribute to the overall noise level. The design of these fans, their speed, and the materials used in their construction can influence the noise generated by the cooling system.

For instance, a portable generator designed for camping purposes might prioritize reduced noise levels for a quiet outdoor experience. In contrast, an industrial generator built for heavy-duty applications may prioritize power output over noise reduction, resulting in a louder operation.

Understanding the various factors contributing to generator noise is vital for consumers looking to make informed choices based on their specific needs and preferences. Noise reduction technologies and advancements continue to be a focus in the generator industry, aiming to strike a balance between power efficiency and a quieter operation.

How To Make A Generator Quiet?

Generator noise can be a constant nuisance, especially in residential areas where peace and quiet are highly valued. Fortunately, there are various practical strategies you can employ to ensure your generator operates as quietly as possible. Here are our top 25 tips on how to make a generator quiet:

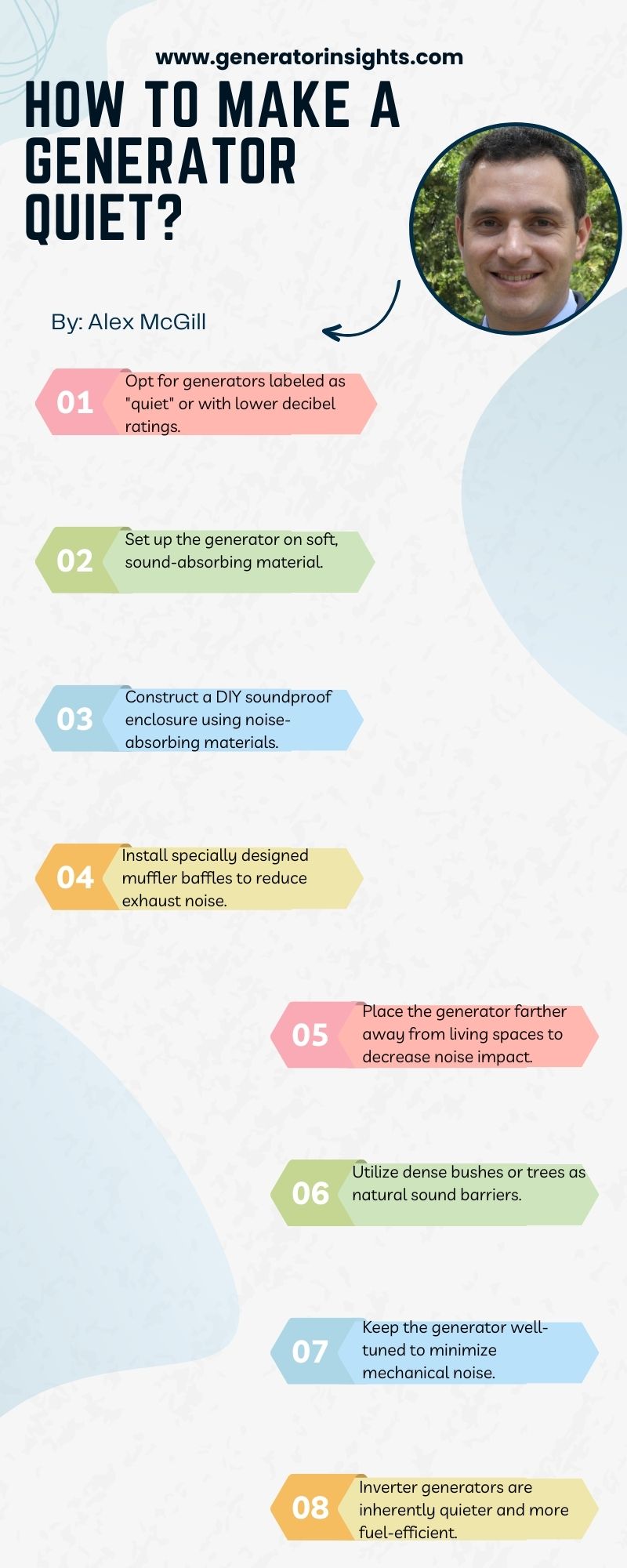

- Choose a Quiet Generator Model: Opt for generators with lower decibel levels, typically labeled as “quiet” models. Brands like Honda and Yamaha are known for producing generators with reduced noise output.

- Install a Generator Silencer: Attach a generator silencer or muffler to the exhaust system. This addition significantly dampens the sound produced during operation.

- Use a Soundproof Enclosure: Construct or invest in a soundproof enclosure for your generator. This can be a purpose-built structure or a DIY project using sound-absorbing materials.

- Adjust Generator Placement: Position the generator strategically, taking into account the direction of the exhaust and placing it farther away from living or working spaces.

- Invest in Anti-Vibration Pads: Place anti-vibration pads under the generator to absorb and dampen vibrations, reducing both noise and wear on the generator.

- Check and Tighten Loose Parts: Regularly inspect the generator for loose components such as bolts, nuts, or panels. Tightening these parts can prevent rattling and additional noise.

- Modify the Exhaust Pipe: Extend and redirect the exhaust pipe to guide noise away from areas where it can be disruptive. Consider using flexible pipe extensions to achieve optimal placement.

- Install a Baffle Box: Create or purchase a baffle box designed to trap and absorb noise before it escapes. This can be particularly effective for portable generators.

- Opt for Inverter Generators: Inverter generators are generally quieter than traditional models, as they adjust the engine speed based on the required load, reducing overall noise levels.

- Use Noise-Reducing Extension Cords: Employ extension cords designed with noise reduction in mind. These cords can minimize electrical interference, especially if your generator powers sensitive electronics.

- Install Soundproofing Material: Line the generator enclosure with soundproofing materials such as acoustic foam or mass-loaded vinyl to absorb and block noise effectively.

- Maintain Regular Generator Maintenance: Keep up with routine generator maintenance, including oil changes and filter replacements. A well-maintained generator tends to operate more quietly.

- Invest in a Generator Noise Reduction Box: Purchase or build a noise reduction box specifically designed for generators. These boxes often feature sound-absorbing materials and proper ventilation.

- Create a Barrier with Foliage: Plant dense vegetation around the generator to act as a natural sound barrier. This not only adds aesthetic value but also helps in noise reduction.

- Use Rubber Grommets: Replace metal screws and bolts with rubber grommets wherever possible. This helps minimize vibrations, which are a significant contributor to generator noise.

- Choose the Right Fuel Type: Some fuel types burn quieter than others. Propane, for example, tends to produce less noise compared to gasoline or diesel.

- Install a Generator Muffler: Upgrade your generator’s muffler to a high-quality, aftermarket option. This can make a substantial difference in reducing exhaust noise.

- Apply Mass Loaded Vinyl: Attach mass-loaded vinyl to the generator’s housing. This dense material effectively dampens sound and can be a valuable addition to your noise reduction efforts.

- Create a DIY Noise Barrier: Build a barrier around the generator using materials like plywood or foam. This makeshift barrier can deflect and absorb sound waves, reducing overall noise.

- Install a Noise Reduction Air Filter: Opt for an air filter designed specifically to reduce the noise produced during the generator’s air intake process.

- Implement Remote Start Technology: Utilize remote start technology if your generator supports it. This allows you to start the generator from a distance, minimizing the initial noise impact.

- Check and Tighten Belts: Inspect the generator’s belts for signs of wear and tear. Tighten or replace them as needed to reduce noise associated with belt movement.

- Utilize Generator Baffles: Install baffles on the generator. These devices disrupt and absorb sound waves, especially those emanating from the exhaust.

- Monitor Exhaust Temperature: Lowering the exhaust temperature can contribute to reducing noise levels. Consider modifications such as additional cooling or insulation to achieve this.

- Consult Professional Installation: When in doubt or if you want a tailored solution, seek the expertise of professionals. They can advise on optimal generator placement and additional noise reduction measures for your specific situation.

Combining several of these strategies tailored to your generator’s make and model can result in a significantly quieter operation, allowing you to enjoy the benefits of backup power without the disruptive noise.

Now let’s discuss some key points in more detail.

Choose the Right Generator

Choosing the right generator can make a big difference in noise levels – so you want to pick one that suits your needs. There are two different types of generators: traditional and inverter generators. Traditional generators tend to be louder than inverter generators, but they also provide more power and cost less. Inverter generators, on the other hand, are quieter and more energy-efficient while costing more upfront.

When deciding between a traditional or an inverter generator, consider factors such as budget, power output requirements, portability needs, and sound levels.

To make a generator quieter still, look into purchasing or building soundproof boxes for camping use or homemade exhaust silencers to reduce engine noise. You may also want to consider investing in accessories such as foam insulation and acoustical blankets for additional sound reduction throughout the entire system.

With these options available to you, it’s easy to find something that will work best for you when trying to make your generator quiet – no matter where it is located!

Location

Placing your generator in the right location can drastically reduce noise levels, so take time to scout out the ideal spot for it.

Some tips are to find a spot with natural obstacles like trees or buildings that will block sound from traveling too far. It is also helpful to build a generator box or soundproof box for the generator, which can help make it quieter.

All these strategies combined can result in significant noise reduction and help make sure your generators don’t disturb anyone else’s peace and quiet.

Face the Exhaust Pipes Up or Away from You

Facing the exhaust pipes away from you can help prevent loud echoes and reverberations, ensuring a peaceful camping experience. This can be done by either angling the generator so the exhaust is pointing up or away from you. If possible, it is best to face the exhaust away from any tents, campers, or other living areas that could be disturbed by noise.

Build a Quiet Enclosure

Constructing a soundproof box around your generator can dramatically reduce its noise level, allowing you to enjoy the outdoors in peace without having to worry about it being too loud.

Materials needed for building a generator quiet box include wood, plywood, insulation, and foam. Measure the size of the generator and cut the wood pieces according to those measurements.

Make sure that all edges are sealed as tightly as possible with foam or weather stripping. Insulate all sides of the wooden box with foam or fiberglass insulation which will help absorb sound from escaping out of any gaps.

To make sure your generator is securely mounted inside the enclosure and won’t move around while running, use straps to fasten it in place. With these steps completed you can now enjoy using your generator without disturbing anyone else in your vicinity. Taking extra steps like adding sound deflectors will further improve noise reduction capabilities of this setup.

Use Sound Deflectors

Positioning sound deflectors strategically around your enclosure can significantly reduce its noise output, allowing you to relax without any distractions. Using sound deflectors to dampen the noise of a generator requires:

- Thick materials that absorb sound waves

- Adequate space between the walls of the enclosure and the machine

- Properly angled surfaces to bounce sound away from where it is not wanted

- Coverings of perforated metal sheets for further deflection of unwanted noise

- A good sealant to ensure that no gaps are present in the structure. By taking these measures into consideration, you can be sure that your generator has been properly insulated so as to minimize its disruptive sounds. This will provide an effective solution for reducing generator noise and creating a quieter environment.

Place The Generator On a Soft Surface

Placing the generator on a soft surface, like rubber or foam, can drastically reduce its noise output and make your space much quieter.

For example, installing a rubber mat underneath an outdoor generator in a suburban backyard resulted in sound levels being reduced by 50%. This is because these materials absorb vibrations from the generator which would otherwise be amplified through other surfaces.

Furthermore, they act as insulation to muffle the sound of the engine. With this simple step alone you will already notice a big difference in terms of noise pollution. To further reduce noise levels, adding a larger muffler can provide even more relief.

If you are new to generators and want to know more about these powerhouses, we recommend you read our guide on what is a generator, what is a portable generator, what is a power generator and what is an inverter generator. These articles can help you understand these miraculous devices and their working easily.

Add a Larger Muffler

Adding a larger muffler to your generator can significantly reduce the noise level and create a much calmer environment. There are three different types of mufflers available: absorptive, reflective and dissipative.

Each type of muffler has its own unique advantages – absorptive mufflers absorb sound waves, reflective ones reflect them away from the source, and dissipative mufflers scatter them.

The benefits of adding a larger muffler include reducing noise levels, minimizing environmental pollution, increasing efficiency by reducing back pressure on the engine, and improving fuel consumption.

Installing a larger muffler is relatively easy if you have basic mechanical knowledge. Firstly disconnect the exhaust pipe from the engine and remove any old gaskets or clamps before you install the new one. Make sure it fits snugly in place with no gaps before replacing any gaskets or clamps that were removed earlier. Finally connect it to the existing exhaust pipe using either welding or connecting brackets depending on what fits best for your application.

With these steps completed, you’ll have successfully added a larger muffer to help make your generator quieter!

Use Water As Your Generator Muffler

Using water as your generator muffler is an effective way to reduce noise levels and create a more peaceful atmosphere. It works by having the exhaust pass through a container of water, which acts as a barrier between the source of the sound and its destination. This causes vibrations to be absorbed before they reach the intended location, resulting in significantly reduced noise levels.

By controlling the amount of water used in this process, you can adjust how much sound is attenuated according to your needs. With this method, you can avoid using expensive materials that may not always provide satisfactory results. The cost-effective nature of this approach makes it one of the most popular methods for reducing noise from generators.

Additionally, it’s relatively easy to set up and does not require any special skills or tools to do so. Consequently, it’s a great option for anyone looking for a quiet generator solution without having to break the bank. As such, using water as your generator muffler is definitely worth considering when trying to keep noise levels down.

The next step is to use a sound attenuation system such as baffles or insulation panels in order to further reduce noise emissions from your generator.

Use a Sound Attenuation System

Another option for making your generator quieter is to install a sound attenuation system. Unlike water, which serves as an external muffler, sound attenuation systems block the noise before it even leaves the generator by using internal components. There are several different types of sound attenuation systems depending on the size and power of your generator. The benefits to this method include reduced noise pollution from the generator, improved air quality at the site of use, and increased safety due to reduced resonance or vibration.

The installation process for these systems depends on the type you choose but typically involves a combination of insulation materials and acoustic panels that are either bolted directly onto the engine enclosure or mounted inside it. It’s important to consult with an expert when installing these systems as improper setup can lead to damage or ineffective muffling. With proper installation however, you’ll be able to enjoy a quiet environment without any additional hassle.

Use Rubber Grommets

When aiming to reduce generator noise, paying attention to the mechanical components is crucial. Replace metal screws and bolts with rubber grommets to address one of the primary sources of noise – vibrations. Vibrations generated by the operation of the generator can resonate through metal components, amplifying the overall noise level. By using rubber grommets, you introduce a flexible and dampening material that absorbs vibrations before they have a chance to reverberate.

Installing rubber grommets at key points where metal parts connect can have a noticeable impact on noise reduction. Focus on areas where the generator attaches to its frame or any components that may vibrate during operation. This simple yet effective solution not only helps in minimizing noise but also contributes to the overall stability and longevity of the generator by reducing wear and tear on metal parts.

Choose the Right Fuel Type

The choice of fuel plays a significant role in the noise output of a generator. Different fuel types burn in distinct ways, resulting in varying noise levels. Propane, for example, tends to produce less noise compared to gasoline or diesel. This is because propane combustion generally occurs more efficiently and with fewer explosive sounds.

When selecting a generator or deciding on the fuel type to use, consider the environment and noise regulations in your area. While propane is known for its quieter combustion, it’s essential to balance this consideration with other factors like cost and availability. Understanding the noise characteristics of different fuels allows you to make an informed decision that aligns with your specific requirements.

Apply Mass Loaded Vinyl

To address airborne noise produced by the generator, focusing on the generator’s housing is crucial. Attach mass-loaded vinyl to the generator’s housing as a strategic measure to dampen sound effectively. Mass-loaded vinyl is a dense and flexible material designed to block and absorb sound waves, preventing them from escaping the generator enclosure.

When applying mass-loaded vinyl, cover areas with high noise potential, such as the sides and top of the generator. Ensure a tight and secure fit to create a barrier that inhibits the transmission of sound. This addition not only helps in reducing the overall noise level but also contributes to creating a more acoustically controlled environment around the generator.

Consider combining the application of mass-loaded vinyl with other soundproofing measures for comprehensive noise reduction. This can include using sound-absorbing materials on the interior of the generator enclosure and addressing any potential gaps or openings that could allow sound to escape.

Troubleshooting Common Generator Issues

Generators are indispensable during power outages, ensuring a continuous power supply. However, users may encounter issues that hinder their optimal performance. Below is a comprehensive guide to troubleshoot common generator issues and restore seamless operation.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| 1. Engine Fails to Start | – Silent operation | – Check fuel levels and ensure there’s an adequate supply. |

| – Starter motor cranks but fails to ignite | – Inspect the spark plug for signs of damage or wear. Replace if necessary. | |

| – Strong smell of gasoline | – Examine the carburetor for blockages and clean or replace if needed. | |

| 2. Low Power Output | – Dimming lights and fluctuating power output | – Verify the load capacity and ensure it doesn’t exceed the generator’s limit. |

| – Appliances not running at full capacity | – Inspect the voltage regulator for malfunctions and replace if necessary. | |

| 3. Generator Overheating | – Unusual heat emanating from the generator | – Check the cooling system, including the radiator and coolant levels. Clean or replace components as required. |

| – Frequent shutdowns due to overheating | – Ensure proper ventilation around the generator and clean any debris obstructing airflow. | |

| 4. Excessive Noise Levels | – Unusual or loud sounds during operation | – Inspect the muffler for damage and replace if needed. Adjust engine RPM to recommended levels. |

| – Vibrations and rattling noises | – Tighten any loose bolts and secure all components properly. | |

| 5. Electric Shock from Generator | – Users experiencing electric shocks | – Immediately disconnect the generator from the power source. Inspect and repair any damaged wiring or outlets. |

| – Tingling sensation when touching the generator | – Check for grounding issues and ensure the generator is properly grounded. | |

| 6. Smoke Emission | – Visible smoke during operation | – Examine the oil level and quality. Change oil if it appears dirty or insufficient. |

| – Unpleasant burning smell | – Inspect the air filter for clogs and replace if necessary. | |

| 7. Fuel Leaks | – Noticeable fuel odors or wet spots around the generator | – Check the fuel lines and connections for leaks. Replace any damaged components. |

| – Decreased fuel efficiency | – Tighten loose fuel fittings and ensure the fuel tank is securely sealed. | |

| 8. Battery Issues | – Difficulty starting the generator | – Inspect the battery for corrosion or loose connections. Replace if necessary. |

| – Weak or dead battery | – Charge or replace the battery as needed. | |

| 9. Generator Running Rough | – Uneven or shaky operation – Check the air-fuel mixture; adjust the carburetor to ensure the correct ratio. Inspect for clogged fuel injectors. | – Fluctuating RPMs – Inspect the ignition system for issues. Replace faulty spark plugs or ignition coils as necessary. |

Addressing these common generator issues promptly will help maintain the reliability of your power source. If problems persist, consider seeking professional assistance for more complex diagnostics and repairs.

Generator Maintenance Tips

Power outages can strike unexpectedly, making a well-maintained generator crucial for ensuring a continuous power supply. Regular maintenance not only enhances longevity but also guarantees optimal performance. Here are some key tips to keep your generator in top shape:

- Scheduled Inspections: Conduct routine checks on your generator to identify any signs of wear, loose connections, or potential issues before they escalate.

- Fluid Levels: Regularly check and replenish the oil and fuel levels to guarantee efficient operation. Proper lubrication is essential for preventing friction-related damage.

- Battery Health: Ensure the generator’s battery is charged and in good condition. A healthy battery is vital for a swift start when power is needed.

- Air Filter Checks: Keep the generator’s air filter clean and replace it as recommended by the manufacturer. A clogged filter can compromise performance and fuel efficiency.

- Coolant System Inspection: Verify the coolant levels and inspect the system for leaks. Overheating can lead to severe damage, so maintaining the right coolant levels is crucial.

- Capacitor Maintenance: Check and test the generator’s capacitors regularly. Faulty capacitors can lead to electrical issues, affecting the generator’s ability to produce a consistent power output.

- Run the Generator Regularly: Regularly starting the generator, even if it’s not in use, helps keep the engine components lubricated and prevents fuel system issues.

- Storage Considerations: If the generator is stored for an extended period, use a fuel stabilizer to prevent fuel deterioration. Empty the fuel tank or run the generator dry before storage to avoid gumming.

By adhering to these maintenance tips, you’ll ensure that your generator is ready to provide reliable power when you need it the most.

Generator Safety Tips

Generators are indispensable for providing power during outages, but ensuring their safe operation is paramount. Here are essential Generator Safety Tips to keep in mind:

- Proper Ventilation: Always operate generators in well-ventilated areas to prevent the buildup of harmful gases like carbon monoxide.

- Read the Manual: Familiarize yourself with the manufacturer’s guidelines for your specific generator model to understand its unique safety requirements.

- Regular Maintenance: Conduct routine checks on the generator, including fuel lines, filters, and oil levels, to guarantee optimal performance and identify potential issues early.

- Keep Flammable Materials Away: Position the generator away from flammable materials to reduce the risk of fire hazards.

- Carbon Monoxide Alarms: Install and regularly test carbon monoxide detectors near the generator area to provide an early warning of any dangerous gas levels.

- Grounding: Ensure proper grounding of the generator to prevent electrical shocks and protect both the equipment and users.

- Fuel Safety: Store fuel in approved containers, away from heat sources, and follow guidelines for proper storage to avoid spills and contamination.

- Emergency Shutdown: Understand and practice the emergency shutdown procedures to swiftly respond to potential dangers.

- Children and Pets: Keep children and pets away from the generator during operation to prevent accidents and injuries.

- Avoid Overloading: Respect the generator’s rated capacity and avoid overloading it to maintain efficient and safe operation.

- Cooling Time: Allow the generator to cool down before refueling to prevent accidental fires or burns. Follow the recommended cooldown period specified in the manual.

- Secure Placement: Place the generator on a stable, flat surface to prevent tipping and ensure safe operation. Avoid placing it on uneven or sloped terrain.

- Regular Testing: Periodically run the generator to ensure it starts easily and operates smoothly. This practice helps identify potential issues before they become major problems during an emergency.

- Extension Cord Safety: If using extension cords, ensure they are of sufficient gauge for the load and in good condition. Overloading cords can lead to overheating and pose a fire risk.

- Weather Considerations: Shelter the generator from the elements to protect it from rain and snow. Use appropriate covers or enclosures designed for your specific generator model.

- Professional Inspection: Schedule regular professional inspections to check for hidden issues and ensure all components are in good working order. This is especially important for standby generators.

- Emergency Services Awareness: Familiarize yourself with the location of emergency shut-off switches and how to quickly contact relevant services in case of a malfunction or emergency.

- Storage Precautions: If the generator is not in use for an extended period, follow proper storage procedures. This includes draining the fuel, disconnecting the battery, and storing it in a dry, cool place.

- Educate Users: Ensure that anyone who may need to operate the generator is familiar with its safety features and operation. Provide clear instructions to prevent accidents caused by misuse.

- Legal Compliance: Be aware of and adhere to local regulations regarding generator usage, emissions, and noise levels. Non-compliance may result in fines or other penalties.

Remember, adhering to these Generator Safety Tips is crucial to ensure the reliable and secure use of your generator.

Conclusion

In conclusion of how to make a generator quiet, we discussed that you don’t have to put up with the noise your generator produces. By following these tips, you can make your generator much quieter and more tolerable. Use insulation to reduce sound vibrations from escaping, add a muffler to soften the engine noise, and position the generator away from populated areas. These simple steps are sure to bring peace and quiet back into your life. Symbolically, this silence is like a breath of fresh air that washes away all of the stress caused by loud noises before. Take control of your environment and give yourself permission to enjoy the serenity that a quiet generator brings.

References

- Control of electric generators: a review

- Significant power enhancement of magneto-mechano-electric generators by magnetic flux concentration

- Performance and power management of droplets-based electricity generators

- Towards modelling and design of magnetostrictive electric generators

Frequently Asked Questions

What types of noise reduction techniques can be used?

You can use acoustic insulation, sound baffles, and silencers to reduce noise. Installing a muffler or using sound-absorbing materials can also help make the generator quieter.

Can I use a generator indoors?

You can use a generator indoors, but it’s important to take noise reduction into account. Use techniques like soundproofing and mufflers to reduce the noise level.

How much maintenance is required to keep a generator quiet?

You’ll need to regularly maintain your generator to keep it running quietly. Change the oil, clean the air filter, and check for any worn parts. This will help reduce noise and keep your generator running smoothly.

What is the best type of generator for a quiet operation?

You should look into inverter generators as they are designed to be quieter and more efficient. They can offer a much quieter operation than traditional generators, making them ideal for your needs.

What safety precautions should be taken when using a generator?

Always use a generator in well-ventilated areas, and keep it away from flammable materials. Wear appropriate safety gear when refueling or handling the generator, and never touch it with wet hands. Keep children away from the generator at all times.

How do you reduce the noise of a generator?

To make a regular generator quieter, consider purchasing a generator that meets your specific needs. It’s also effective to point the exhaust pipes away or upward, move the generator further away, place it on a soft surface, use sound deflectors, build an acoustic enclosure, replace the muffler, or use water as a muffler.

Can you make a regular generator quieter?

Yes, a regular generator can be made quieter. One approach is to use anti-vibration mounts underneath the generator to isolate vibrations and decrease noise transmission. Options such as rubber mounts, spring mounts, or dampers can be chosen based on the desired noise level.

Can you put a silencer on a generator?

Yes, it is possible to install a silencer on a generator. Generator silencers come in various designs, with reactive silencers being one type that effectively reduces noise by bouncing it around inside one or multiple chambers. This design is particularly suitable for low to moderate noise level requirements.