In the hum of uncertainty during power outages, portable generators emerge as silent heroes, ready to illuminate our homes. Amidst the excitement of owning one, a common question echoes: What type of oil do portable generators use? It’s a query born out of a desire for reliability and longevity. Like any companion, these generators have their preferences.

So, let’s embark on a journey to understand their oil needs, ensuring our power allies thrive. After all, knowing the right blend for their well-being ensures they reciprocate with unwavering support during those crucial moments of darkness.

Jump to a Specific Section

- 1 Key Takeaways

- 2 What is a Portable Generator and How Does it Work?

- 3 How Does a Portable Generator Produce Power?

- 4 Why Does a Portable Generator Need Oil?

- 5 What Type of Oil Do Portable Generators Use?

- 6 Different Types of Oil for Portable Generators

- 7 How to Choose the Right Type of Oil for Your Portable Generator?

- 8 Is the Generator Engine 2 Stroke or 4 Stroke?

- 9 How to Change Oil of Your Portable Generator?

- 10 How Often Should You Change the Oil in Your Generator

- 11 Can You Run a Generator Without Oil?

- 12 Impact of Neglected Maintenance

- 13 Tips for Properly Checking and Maintaining Generator Oil Levels

- 14 Common Mistakes to Avoid When Changing Generator Oil

- 15 How to Properly Store Your Portable Generator Oil?

- 16 Portable Generator Maintenance Tips

- 17 Portable Generator Safety Tips

- 18 Conclusion

- 19 References

- 20 Frequently Asked Questions

- 20.1 Can I Use the Same Type of Oil in All Portable Generator Models?

- 20.2 Is It Necessary to Use Synthetic Oil in My Portable Generator?

- 20.3 How Often Should I Check the Oil Level in My Generator?

- 20.4 What Are Some Common Mistakes to Avoid When Changing the Oil in a Generator?

- 20.5 Are There Any Specific Oil Considerations for Operating a Portable Generator in Extreme Weather Conditions?

- 20.6 Can I use any 10w30 oil in my generator?

- 20.7 What kind of oil do you put in a generator set?

- 20.8 Can you use lawnmower oil in a generator?

Key Takeaways

- Regular oil changes and maintenance are important for the smooth operation and longevity of portable generators.

- Different generator models may require different types and viscosities of oil, so following manufacturer recommendations is crucial.

- Using the wrong oil type can result in engine damage and void the warranty, so it is important to verify compatibility before using alternative options.

- Synthetic oil offers better lubrication and resistance to breakdown at high temperatures, while conventional oil is more affordable and works well for intermittent use. The choice between synthetic and conventional oil depends on factors such as usage frequency, operating conditions, and budget.

What is a Portable Generator and How Does it Work?

A portable generator is a versatile device that provides a convenient source of electricity, especially in situations where a traditional power source may be unavailable. These generators are designed for mobility, allowing users to move them easily to different locations. Portable generators are commonly used during power outages, outdoor activities, camping trips, and construction sites.

So, how does a portable generator work? These generators operate on the principle of electromagnetic induction. The primary components include an engine, an alternator, a fuel system, and a control panel. The engine, often powered by gasoline or propane, drives the alternator. The alternator, in turn, produces electrical power. This power is then channeled through the control panel, which allows users to regulate the output and connect various devices.

During operation, the engine burns fuel, producing mechanical energy that drives the alternator’s rotor. This rapid rotation induces a flow of electrons in the conductive coils within the alternator, generating an electric current. The control panel enables users to manage the generator’s output, ensuring compatibility with different devices and preventing overloading.

One essential consideration when using a portable generator is to match the power requirements of connected devices with the generator’s capacity. It’s crucial not to exceed the generator’s wattage limit to prevent damage to both the generator and the devices connected to it.

For example, if you’re running essential household appliances during a power outage, you might use a portable generator with a wattage capacity suitable for powering refrigerators, lights, and charging devices. This practical application demonstrates the importance of understanding both the generator’s capabilities and the power requirements of your specific needs.

How Does a Portable Generator Produce Power?

Portable generators are versatile machines that provide on-the-go power, often crucial during emergencies or outdoor activities. Understanding how these generators produce power involves delving into their key components and processes.

- Fuel Source: Portable generators typically run on common fuels like gasoline, propane, or diesel. The fuel is stored in a tank attached to the generator.

- Internal Combustion Engine: The heart of a portable generator is its internal combustion engine. This engine operates similarly to a car engine, converting fuel into mechanical energy.

- Mechanical Energy to Alternating Current (AC): The engine’s mechanical energy is then transformed into electrical energy through an alternator. The alternator contains a coil of wire that rotates within a magnetic field, inducing an alternating current (AC).

- Conversion to Direct Current (DC): While the alternator initially produces AC, many appliances use direct current (DC). The generator includes a component called a rectifier that converts the AC to DC, making it compatible with various devices.

- Voltage Regulation: To ensure a stable power supply, portable generators incorporate voltage regulators. These devices control the output voltage, preventing fluctuations that could damage sensitive electronics.

Understanding the process of power generation in portable generators helps users make informed decisions when selecting, operating, and maintaining these essential devices.

Why Does a Portable Generator Need Oil?

Portable generators, like any other internal combustion engine, require oil to function properly and efficiently. The oil in a portable generator serves several crucial purposes, primarily lubrication and cooling. Without oil, the various moving parts inside the generator engine would experience excessive friction, leading to increased wear and tear. This friction generates heat, and without proper lubrication, the components can become damaged over time. Additionally, oil plays a vital role in dissipating heat away from the engine, preventing it from overheating during extended use.

The lubrication provided by oil helps reduce friction between the engine’s piston and cylinder, ensuring smooth movement and preventing premature wear. As the engine operates, it generates heat due to the combustion process. The oil absorbs this heat and carries it away from critical engine components, such as the cylinder walls and pistons. In essence, oil acts as a protective barrier, preserving the longevity and efficiency of the generator.

Regularly checking and changing the oil in your portable generator is essential to maintain its optimal performance and prevent potential damage. Failure to do so could lead to increased friction, overheating, and, eventually, engine failure. It’s a straightforward but crucial maintenance task that ensures your portable generator remains a reliable source of power when you need it most.

What Type of Oil Do Portable Generators Use?

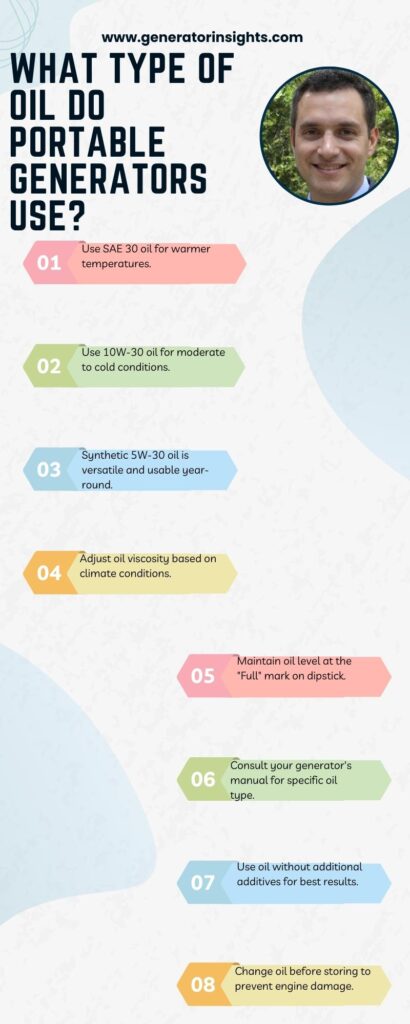

Portable generators typically use different types of oil depending on the temperature range in which they are operated. Here are the recommended oil types for portable generators based on temperature:

- Above 32°F (0°C): Use SAE 30 oil. This viscosity grade is suitable for warmer temperatures and provides proper lubrication in those conditions.

- Between 40°F (4°C) and -10°F (-23°C): Use 10W-30 oil. This multi-viscosity oil is designed to perform well in a range of temperatures, making it suitable for moderate to cold conditions.

- In all temperature ranges: Synthetic 5W-30 oil can be used. Synthetic oils have excellent low-temperature flow properties and can also perform well in warmer conditions. They provide versatility and can be used year-round.

It’s important to note that the oil should be changed after the first 20-30 hours of operation and then every 100 hours of run time thereafter. Regular oil changes help maintain the generator’s performance and longevity.

Different Types of Oil for Portable Generators

Choosing the right oil for your portable generator is crucial for ensuring optimal performance and longevity. The type of oil you use directly impacts the engine’s efficiency and overall functionality.

| Oil Type | Description | Recommended Viscosity |

|---|---|---|

| SAE 10W-30 | A versatile oil suitable for various temperature ranges. | Ideal for moderate climates |

| SAE 5W-30 | Cold-weather option, flows easily during startup. | Best for colder climates |

| SAE 30 | For warmer climates and consistent operating temperatures. | Good for stable conditions |

| Synthetic Oil | Engineered for high-performance and extended durability. | Maintains viscosity in extreme temperatures |

| Conventional Oil | Standard oil derived from crude, suitable for basic needs. | Economical and widely available |

When selecting oil for your portable generator, consider the ambient temperature of your location. In colder climates, opt for oils with a lower viscosity like SAE 5W-30 or Synthetic Oil to ensure easy startup. In moderate or warmer climates, SAE 10W-30, SAE 30, or Conventional Oil are suitable choices, providing the right level of protection for your generator’s engine. Always consult your generator’s manual for specific recommendations and to maintain warranty coverage.

How to Choose the Right Type of Oil for Your Portable Generator?

Choosing the right type of oil for your portable generator is crucial for its optimal performance and longevity. The oil you select plays a vital role in lubricating the engine, reducing friction, and dissipating heat. In this section, we’ll break down the factors to consider when selecting oil for your portable generator.

1. Check the Manufacturer’s Recommendations

Always refer to your generator’s manual for the manufacturer’s recommended oil type and viscosity. Different generators may have specific requirements, and using the wrong oil can lead to poor performance and potential damage. Common oil types include 10W-30 or 5W-30.

2. Consider Ambient Temperature

Ambient temperature influences the oil’s viscosity, affecting how well it flows. For colder climates, a lower viscosity oil like 5W-30 is suitable, as it flows more easily in cold conditions. In warmer climates, 10W-30 might be preferable. Ensure the chosen oil matches the temperature range of your operating environment.

3. Understanding Oil Viscosity

Oil viscosity is denoted by the numbers on the bottle, such as 10W-30. The first number (e.g., 10W) represents the oil’s flow characteristics in cold temperatures, while the second number (e.g., 30) indicates its performance at operating temperatures. Strike a balance based on your region’s temperature variations.

4. Synthetic vs. Conventional Oils

Consider the benefits of both synthetic and conventional oils. Synthetic oils generally offer better stability across a broader temperature range, improved lubrication, and longer change intervals. While they may be more expensive, they could provide enhanced protection, especially in extreme conditions.

5. Oil Change Frequency

The frequency of oil changes depends on usage and operating conditions. Heavy usage or extreme temperatures may require more frequent changes. Regular oil changes are essential to remove contaminants and ensure the engine runs smoothly.

For instance, if you live in a region with fluctuating temperatures, such as New England, where winters are cold and summers are warm, a multi-viscosity oil like 10W-30 might be a suitable choice. It provides proper lubrication during cold starts while maintaining stability in warmer weather.

Thus, choosing the right oil for your portable generator involves considering factors like the manufacturer’s recommendations, ambient temperature, oil viscosity, and the benefits of synthetic vs. conventional oils. By making an informed choice, you can ensure optimal generator performance and extend its lifespan.

Is the Generator Engine 2 Stroke or 4 Stroke?

When considering the operational mechanism of a generator engine, one crucial factor to understand is whether it operates on a 2-stroke or 4-stroke cycle. The fundamental difference lies in the number of strokes or movements the engine’s piston makes to complete one combustion cycle. A 2-stroke engine completes a cycle in two movements – compression and combustion, while a 4-stroke engine takes four strokes – intake, compression, power, and exhaust.

In a 2-stroke engine, the compression and combustion phases occur in a single upward and downward movement of the piston. This simplicity allows for a lighter and more compact design, making 2-stroke engines suitable for applications where weight and size are critical factors. They are often found in smaller power tools, mopeds, and some portable generators. However, the trade-off for this simplicity is typically higher fuel consumption and emissions.

On the other hand, 4-stroke engines are more common in larger generators and vehicles. The additional strokes in the cycle allow for better fuel efficiency and reduced emissions. Each stroke has a dedicated function – intake brings in the fuel-air mixture, compression compresses it, power is the combustion itself, and exhaust expels the spent gases. While 4-stroke engines tend to be heavier and bulkier, their efficiency makes them preferable for larger applications where sustained power output and environmental considerations are crucial.

In summary, the choice between a 2-stroke and 4-stroke generator engine depends on the specific requirements of the application. Smaller, portable generators may opt for the simplicity and compactness of a 2-stroke design, while larger generators prioritize the fuel efficiency and lower emissions of a 4-stroke configuration.

How to Change Oil of Your Portable Generator?

Regularly changing the oil in your portable generator is crucial for maintaining optimal performance and extending its lifespan. Here’s a step-by-step guide to help you through the process:

- Gather Materials:

- Ensure you have the correct type and amount of oil for your generator. Refer to the user manual for specifications.

- Have a drain pan, funnel, socket wrench, and a rag handy.

- Safety First:

- Turn off the generator and let it cool down.

- Disconnect the spark plug to prevent accidental starts.

- Locate the Oil Drain Plug:

- Identify the oil drain plug on the bottom of the generator engine. Refer to the manual if unsure.

- Position the Generator:

- Place the generator on a level surface to ensure proper drainage.

- Drain the Old Oil:

- Position the drain pan beneath the oil drain plug.

- Loosen the plug using a socket wrench and let the old oil drain completely.

- Replace the Oil Filter (if applicable):

- Some generators have an oil filter. If yours does, replace it according to the manufacturer’s recommendations.

- Add New Oil:

- Use a funnel to pour the recommended amount and type of new oil into the oil fill cap. Check the manual for specifications.

- Check Oil Level:

- Start the generator briefly to circulate the oil, then let it sit for a minute.

- Check the oil level using the dipstick, and adjust if necessary.

- Dispose of Old Oil Properly:

- Take the used oil to a recycling center or an auto parts store for proper disposal.

- Reconnect the Spark Plug:

- Reconnect the spark plug once you’ve completed the oil change.

- Record the Maintenance:

- Keep a record of the oil change, noting the date and hours of operation, to help track future maintenance needs.

Regularly changing the oil in your portable generator is a simple yet crucial task that ensures smooth operation and prolongs the life of your equipment.

How Often Should You Change the Oil in Your Generator

Regular oil changes are crucial for maintaining the performance and longevity of your portable generator. The frequency of oil changes will depend on the usage and manufacturer’s recommendations, but as a general guideline, it is recommended to change the oil every 50-100 hours of operation.

Neglecting regular oil changes can lead to decreased efficiency, increased fuel consumption, and potential engine damage.

Frequency of Oil Changes

Determining the optimal frequency for oil changes in your generator depends on various factors such as usage, operating conditions, and manufacturer recommendations. The recommended oil change interval for portable generators typically ranges from 50 to 100 hours of operation.

However, it is important to consider the following factors when deciding on the frequency of oil changes:

- Usage: Generators that are used frequently or for extended periods of time may require more frequent oil changes compared to those that are used sporadically.

- Operating Conditions: Generators operating in dusty or high-temperature environments may require more frequent oil changes due to increased wear and contamination.

- Type of Oil: The type of oil used in the generator can also impact the recommended oil change interval. Synthetic oils, for example, tend to have longer change intervals compared to conventional oils.

- Manufacturer Recommendations: It is crucial to consult the generator’s manufacturer recommendations for the specific oil change interval that is suitable for your generator model.

Recommended Oil Change Interval

When considering the recommended oil change interval for your generator, it is important to take into account various factors such as usage, operating conditions, and manufacturer guidelines. The frequency of oil changes can vary depending on these factors.

Generally, it is recommended to change the oil in your portable generator every 50 to 100 hours of operation or at least once a year, whichever comes first. However, if your generator is used in extreme conditions or for heavy-duty applications, more frequent oil changes may be necessary.

It is also important to monitor the condition of the oil regularly and look for signs of dirty oil, such as a dark or milky appearance, a burnt smell, or the presence of debris. Regular oil changes will help ensure optimal performance and longevity of your generator.

Can You Run a Generator Without Oil?

Generators are essential devices that provide backup power during outages or in areas without a reliable electricity supply. However, it’s crucial to understand that running a generator without oil is a risky and damaging practice. Oil plays a vital role in the proper functioning of a generator’s engine. The oil lubricates the engine’s moving parts, reducing friction and preventing overheating. Without proper lubrication, the engine can seize up, leading to irreversible damage.

When a generator runs without oil, the internal components can rub against each other, causing excessive heat and friction. This can result in the engine overheating and, ultimately, a breakdown. Generators are designed to operate efficiently with a specific type and amount of oil, and deviating from these recommendations can have severe consequences. Neglecting oil changes and allowing the oil level to drop too low can also lead to similar issues.

To emphasize the point, imagine a car engine without oil—eventually, it would seize up and fail to function. Similarly, a generator requires proper lubrication to maintain its reliability and longevity. In summary, running a generator without oil is not advisable, as it jeopardizes the engine’s well-being and can lead to costly repairs or even the need for a replacement. Regular maintenance, including checking and changing the oil as recommended by the manufacturer, is essential to ensure the smooth operation of a generator.

Impact of Neglected Maintenance

Why is it important to frequently change the oil in your generator and how does neglecting this maintenance impact its performance? Regular oil changes are a crucial part of recommended maintenance for portable generators. Neglecting this task can have serious consequences for the performance and longevity of your generator. Here are four reasons why changing the oil regularly is essential:

- Lubrication: Oil lubricates the moving parts of the generator’s engine, reducing friction and preventing wear and tear. Neglecting oil changes can lead to increased friction and premature engine failure.

- Cooling: Oil helps to cool down the engine by dissipating heat. When the oil is old and dirty, it loses its ability to cool effectively, resulting in overheating and potential damage to the engine.

- Contaminant Build-up: Over time, dirt, debris, and other contaminants can accumulate in the oil. Neglecting oil changes allows these contaminants to build up, which can cause blockages and reduced engine performance.

- Reduced Fuel Efficiency: Dirty oil can increase fuel consumption, leading to decreased fuel efficiency and higher operating costs.

Neglecting regular oil changes can have a detrimental impact on your generator’s performance and lifespan. To ensure optimal performance, it is crucial to follow recommended maintenance schedules and change the oil at the specified intervals.

In the next section, we will discuss tips for properly checking and maintaining generator oil levels.

Tips for Properly Checking and Maintaining Generator Oil Levels

Generators play a crucial role in providing backup power during outages. Regularly checking and maintaining generator oil levels is essential for ensuring their smooth and efficient operation. Here are some practical tips:

- Frequency of Checks:

- Check the oil level before every use and at least once a month during periods of inactivity.

- Frequent checks are vital to catch any issues early on and prevent potential damage.

- Use the Right Oil:

- Always refer to the generator’s manual to determine the correct type and viscosity of oil.

- Using the wrong oil can lead to poor performance and even damage the generator over time.

- Warm-Up Period:

- Allow the generator to run for a few minutes to warm up the oil before checking the levels.

- This ensures a more accurate measurement as cold oil may give a false reading.

- Check on a Level Surface:

- Place the generator on a flat, level surface before checking the oil.

- This ensures an accurate reading, preventing potential overfill or underfill situations.

- Proper Shutdown Procedure:

- Follow the manufacturer’s guidelines for shutting down the generator.

- This allows the oil to settle, providing a more accurate measurement when checking levels.

- Safe Oil Change Practices:

- Change the oil as per the recommended schedule outlined in the manual.

- Use a suitable oil pan and dispose of used oil in an environmentally responsible manner.

- Monitor for Leaks:

- Regularly inspect the generator for any signs of oil leaks.

- Addressing leaks promptly prevents potential damage to the engine and surrounding components.

- Record Keeping:

- Keep a log of oil checks and changes, noting the date and amount added or replaced.

- This helps establish a maintenance routine and provides a reference for any irregularities.

Adhering to these tips ensures that the generator’s oil levels are properly maintained, promoting longevity and reliable performance during critical times.

Common Mistakes to Avoid When Changing Generator Oil

One common mistake to avoid when changing generator oil is failing to use the recommended type and viscosity of oil. Using the wrong type of oil can lead to poor performance, increased wear and tear, and even engine damage. To ensure that you are using the correct oil for your generator, always refer to the manufacturer’s recommendations found in the owner’s manual. Moreover, here are some other common mistakes to avoid and the proper procedure for changing generator oil:

- Neglecting to warm up the generator: Before changing the oil, it is important to run the generator for a few minutes to warm up the oil. This helps to loosen any contaminants and ensures that the oil drains more easily.

- Forgetting to turn off the generator: Always make sure to turn off the generator and disconnect it from any power source before attempting to change the oil. This is a safety precaution that should never be overlooked.

- Not using a drain pan: Use a drain pan to collect the old oil as it drains out of the generator. This will prevent oil from spilling onto the ground and causing environmental damage.

- Overfilling or underfilling the oil: It is crucial to add the correct amount of oil to the generator. Overfilling can cause excessive pressure and damage the engine, while underfilling can lead to insufficient lubrication and increased wear. Always check the oil level using the dipstick or sight glass after adding oil.

How to Properly Store Your Portable Generator Oil?

Properly storing generator oil is crucial for maintaining the efficiency and longevity of your portable generator. Inadequate storage can lead to contamination and deterioration of the oil, impacting the generator’s performance. Follow these guidelines to ensure you store your generator oil effectively:

- Cool and Dry Location:

- Store your generator oil in a cool and dry place to prevent moisture absorption and contamination.

- Avoid areas with extreme temperatures, as both high heat and freezing cold can affect the oil’s viscosity.

- Sealed Containers:

- Use sealed containers to store the generator oil. This prevents exposure to air and contaminants, maintaining the oil’s quality.

- Ensure that the lids are tightly secured to prevent any leaks or spills.

- Labeling:

- Clearly label the containers with the date of purchase and type of oil to track its age and composition.

- This helps you use the oldest oil first and ensures you’re using the right type for your generator.

- Regular Inspections:

- Periodically inspect the oil containers for any signs of damage, leaks, or contamination.

- If you notice discoloration, a foul odor, or debris, it’s an indication that the oil may be compromised and should be replaced.

- Keep Away from Sunlight:

- Store the oil away from direct sunlight, as UV rays can accelerate oil degradation.

- Exposure to sunlight can cause the oil to break down faster, reducing its effectiveness.

- Secure and Elevated Storage:

- Keep the oil containers in a secure location to prevent accidental spills or unauthorized access.

- Elevate the containers slightly to avoid direct contact with the ground, reducing the risk of contamination.

Portable Generator Maintenance Tips

Portable generators are invaluable during power outages, ensuring you have a reliable source of electricity. To keep your generator in top-notch condition, regular maintenance is crucial. Here are some essential tips:

- Oil Check and Change:

- Why: Regularly check the oil level and change it as recommended by the manufacturer.

- How: Refer to your generator’s manual for specific instructions on oil checks and changes.

- Fuel System Inspection:

- Why: Stale fuel can clog the carburetor. Ensure the fuel system is clean for optimal performance.

- How: Use fresh fuel and add a fuel stabilizer if the generator will be stored for an extended period.

- Air Filter Cleaning/Replacement:

- Why: A clogged air filter can reduce efficiency and damage the engine.

- How: Clean or replace the air filter regularly. Refer to the manual for guidance on the frequency.

- Spark Plug Maintenance:

- Why: A dirty or faulty spark plug can affect starting and performance.

- How: Check and clean or replace the spark plug according to the manufacturer’s recommendations.

- Battery Check:

- Why: Ensure the battery is charged to facilitate smooth starts.

- How: Charge the battery regularly, especially during periods of inactivity.

- Cooling System Inspection:

- Why: Overheating can damage the generator. Check the cooling system regularly.

- How: Inspect the cooling fins and ensure they are clean and free of debris.

- Run the Generator Regularly:

- Why: Regular operation prevents stale fuel, lubricates moving parts, and helps identify potential issues.

- How: Run the generator at least once a month with a moderate load for about 30 minutes.

- Storage Considerations:

- Why: Proper storage prevents deterioration during periods of inactivity.

- How: Store the generator in a cool, dry place with a cover to protect it from the elements.

By following these maintenance tips, you can ensure that your portable generator is always ready to provide the power you need when you need it. Regular care extends the life of your generator and enhances its reliability during crucial times.

Portable Generator Safety Tips

Portable generators are handy devices that provide power during outages or in remote locations. However, improper use can lead to accidents. Follow these safety tips to ensure you use your portable generator safely.

- Location Matters:

- Place the generator outside, away from doors and windows, to prevent carbon monoxide buildup.

- Keep it on a dry surface to avoid electrocution risks.

- Ventilation is Key:

- Fuel Safety:

- Store fuel in approved containers away from living areas and heat sources.

- Turn off the generator and let it cool before refueling to prevent fires.

- Grounding:

- Use a grounding rod to connect the generator to the ground, reducing the risk of electrical shock.

- Extension Cords:

- Use heavy-duty extension cords designed for outdoor use to connect appliances.

- Ensure cords are in good condition to prevent electrical hazards.

- Regular Maintenance:

- Follow the manufacturer’s instructions for maintenance to keep the generator running efficiently and safely.

- Overloading Prevention:

- Calculate the wattage needed for appliances and avoid overloading the generator, which can damage both the generator and devices.

Following these guidelines ensures that portable generators provide the necessary power without compromising safety.

Conclusion

In conclusion, understanding the nuances of oil selection for portable generators is key to maximizing their performance and lifespan. What Type of Oil Do Portable Generators Use sheds light on the critical factors that influence this decision. By adhering to manufacturer specifications and considering factors like viscosity and oil type, you can ensure that your generator operates at its best. Regular maintenance, including oil changes, will further contribute to its longevity.

Let this guide be your go-to resource as you navigate the world of generator maintenance, ensuring that your portable power source remains reliable, efficient, and ready to serve whenever you need it.

References

- Should we use a portable generator in an emergency?

- Carbon monoxide poisoning from portable electric generators

- Active-passive control of portable generator set radiated noise

- Studies on control of noise from portable power generator

Frequently Asked Questions

Can I Use the Same Type of Oil in All Portable Generator Models?

Using regular oil in portable generators is not recommended. It is crucial to identify the specific oil type and viscosity recommended by the manufacturer. Some reputable oil brands for portable generators include Honda, Briggs & Stratton, and Generac.

Is It Necessary to Use Synthetic Oil in My Portable Generator?

Using synthetic oil in a portable generator offers several benefits such as improved engine performance, better lubrication, and longer oil change intervals. However, using conventional oil may be a more cost-effective option.

How Often Should I Check the Oil Level in My Generator?

Regularly checking the oil level in your generator is crucial for its proper functioning. Neglecting this important maintenance task can lead to engine damage and costly repairs. Make it a habit to check the oil level at least once a month.

What Are Some Common Mistakes to Avoid When Changing the Oil in a Generator?

When changing the oil in a generator, it is important to avoid common mistakes to ensure proper maintenance. Understanding the proper oil changing procedure, such as using the correct oil type, can help prevent damage and optimize generator performance.

Are There Any Specific Oil Considerations for Operating a Portable Generator in Extreme Weather Conditions?

Operating a portable generator in extreme weather conditions requires specific oil considerations. The performance of the generator can be significantly affected by extreme temperatures. Choosing the best oil brands for portable generators in such conditions is crucial for optimal performance.

Can I use any 10w30 oil in my generator?

Absolutely, any 10W-30 oil is suitable for use in the generator.

What kind of oil do you put in a generator set?

Some common types of oil for generators include SAE 10W-30, a widely used oil for small engines, and SAE 5W-30, recommended for colder temperatures or winter use.

Can you use lawnmower oil in a generator?

Most generators use standard motor oil, so it’s advisable to use the same type of oil suitable for cars or lawnmowers.